Rotary parlors offer continuous cow movement and streamlined milking, enhancing efficiency in large-scale dairy farming pet operations. Parallel parlors allow individual cow access, providing better monitoring and ease of maintenance for smaller herds. Choosing between these systems depends on herd size, labor availability, and desired milking speed for dairy farming pet management.

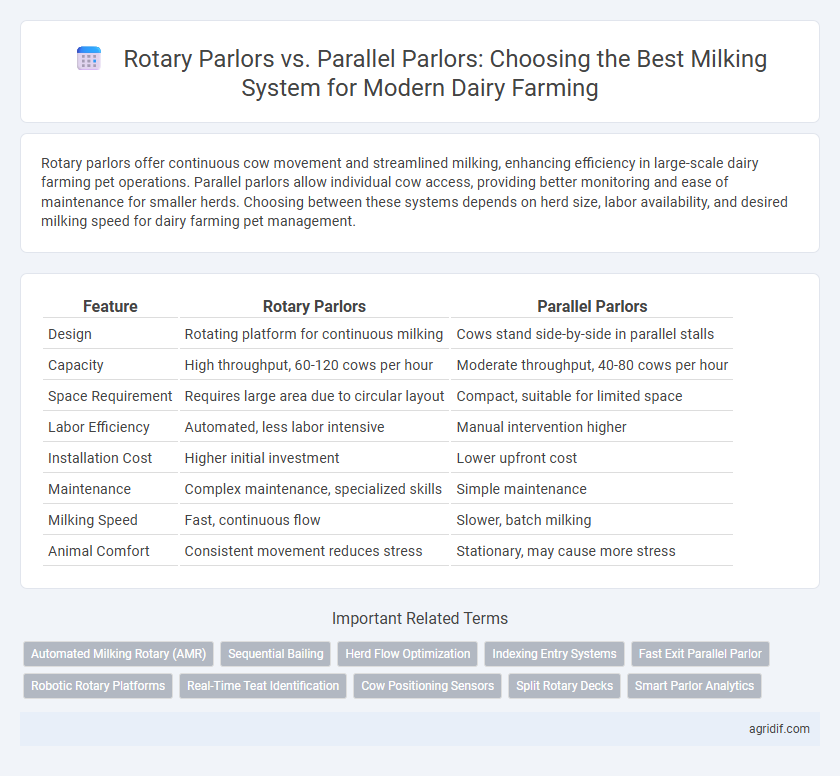

Table of Comparison

| Feature | Rotary Parlors | Parallel Parlors |

|---|---|---|

| Design | Rotating platform for continuous milking | Cows stand side-by-side in parallel stalls |

| Capacity | High throughput, 60-120 cows per hour | Moderate throughput, 40-80 cows per hour |

| Space Requirement | Requires large area due to circular layout | Compact, suitable for limited space |

| Labor Efficiency | Automated, less labor intensive | Manual intervention higher |

| Installation Cost | Higher initial investment | Lower upfront cost |

| Maintenance | Complex maintenance, specialized skills | Simple maintenance |

| Milking Speed | Fast, continuous flow | Slower, batch milking |

| Animal Comfort | Consistent movement reduces stress | Stationary, may cause more stress |

Overview of Milking Parlor Systems

Rotary parlors feature a rotating platform where cows enter, are milked efficiently as the platform moves, and exit, enabling high throughput and space optimization on large dairy farms. Parallel parlors align cows side by side facing away from the operator, allowing easier access to the udder for milking and simplifying cleaning and maintenance. Choosing between rotary and parallel milking systems depends on herd size, labor availability, facility design, and cost considerations.

Introduction to Rotary Parlors

Rotary parlors are advanced milking systems designed to improve efficiency and animal comfort in dairy farming by enabling continuous, circular milking of multiple cows simultaneously. These systems typically accommodate 40 to 100 cows per rotation, significantly reducing milking time compared to parallel parlors, which hold fewer cows and operate in a linear fashion. Incorporating automated features and ergonomic design, rotary parlors optimize milk yield and labor productivity in modern dairy operations.

Introduction to Parallel Parlors

Parallel parlors in dairy farming feature cows standing side-by-side at a 90-degree angle to the pit, allowing easy access to each udder for milking. This configuration improves efficiency by enabling simultaneous attachment of milking units and simplifies cow handling, leading to reduced stress and faster throughput. Parallel parlors are often preferred for small to medium-sized herds due to their space-effective design and lower installation costs compared to rotary systems.

Key Differences Between Rotary and Parallel Parlors

Rotary parlors offer continuous cow flow with a rotating platform, enabling faster milking cycles and higher throughput compared to parallel parlors, which line up cows side-by-side in stationary stalls. Parallel parlors provide easier access for milking and udder inspection, allowing efficient management of each cow individually, while rotary systems emphasize speed and automation for large-scale operations. Operators choose rotary parlors for high-volume herds due to faster processing times, whereas parallel parlors suit medium-sized herds prioritizing detailed cow monitoring and flexibility in milking procedures.

Efficiency and Throughput Comparison

Rotary parlors enable continuous milking with cows entering and exiting stations on a rotating platform, resulting in higher throughput rates of up to 300 cows per hour compared to parallel parlors, which typically process around 120-150 cows per hour. The design of rotary parlors enhances efficiency by reducing cow movement and operator fatigue, allowing for smoother workflow and faster milking cycles. Parallel parlors, while easier to install and maintain, often experience longer turnaround times due to batch processing, affecting overall milking efficiency and limiting throughput capacity.

Labor Requirements and Workflow

Rotary parlors streamline labor requirements by enabling continuous cow rotation, allowing a smaller team to manage milking efficiently and reducing operator fatigue. Parallel parlors necessitate more hands-on labor with cows entering and exiting stalls individually, often slowing workflow and increasing the demand for manual handling. The continuous flow in rotary systems optimizes workflow by minimizing downtime, whereas parallel parlors may experience bottlenecks during cow transitions and cleaning processes.

Animal Comfort and Handling

Rotary parlors provide continuous movement, reducing stress and enhancing animal comfort through smoother transitions and less stationary confinement. Parallel parlors allow easier access for individual cow handling, promoting precise teat sanitation and better monitoring of cow health. Both systems require ergonomic design to minimize discomfort and improve milking efficiency.

Installation Costs and Space Considerations

Rotary parlors typically have higher installation costs due to their complex mechanical design and need for specialized infrastructure, while parallel parlors are generally more cost-effective and easier to install. Space considerations favor parallel parlors in smaller farms as they require less room and fit more easily into existing barn layouts, whereas rotary parlors demand larger, dedicated spaces with circular layouts. Choosing between these systems depends on balancing upfront investment with available space and herd size optimization.

Maintenance and Longevity

Rotary parlors feature complex mechanical components requiring regular maintenance to ensure smooth operation, but their design allows for efficient wear distribution, potentially extending equipment longevity. Parallel parlors have simpler mechanical setups, making maintenance tasks more straightforward and less time-consuming, which can reduce downtime and repair costs. Choosing between the two impacts long-term durability and maintenance schedules, influencing overall operational efficiency in dairy milking systems.

Choosing the Right Milking Parlor for Your Dairy Farm

Rotary parlors offer high throughput and efficiency, ideal for large-scale dairy farms aiming to milk hundreds of cows per hour with minimal labor. Parallel parlors provide greater flexibility and are better suited for smaller herds, allowing easier access to individual cows for health checks and maintenance. Selecting the right milking parlor depends on herd size, labor availability, and desired milking speed to optimize both animal welfare and farm productivity.

Related Important Terms

Automated Milking Rotary (AMR)

Automated Milking Rotary (AMR) systems enhance milking efficiency by allowing continuous cow rotation and simultaneous milking, resulting in higher throughput compared to traditional parallel parlors. AMR technology integrates robotic arms and sensors for precise udder detection and milk extraction, reducing labor costs and improving animal welfare through consistent milking intervals.

Sequential Bailing

Rotary parlors enable continuous milking with cows entering and exiting sequentially, enhancing throughput and reducing labor per cow compared to parallel parlors, where individual stalls require simultaneous manual attention. Sequential bailing in rotary systems optimizes milking efficiency by maintaining a constant workflow, minimizing idle time, and improving cow comfort during the milking process.

Herd Flow Optimization

Rotary parlors enable continuous herd flow by allowing multiple cows to be milked simultaneously in a rotating platform, significantly reducing wait times and improving milking efficiency. Parallel parlors, while easier to manage in smaller herds, often create bottlenecks during peak milking hours due to sequential cow entry and exit, limiting overall herd flow optimization.

Indexing Entry Systems

Rotary parlors provide continuous, automated milking through advanced indexing entry systems, enabling quicker cow movement and higher throughput compared to parallel parlors. Parallel parlors rely on manual or semi-automated indexing, which can slow the milking process and reduce overall efficiency in large-scale dairy operations.

Fast Exit Parallel Parlor

Fast Exit Parallel Parlors offer increased milking efficiency by allowing cows to leave promptly after milking, reducing wait times and enhancing herd throughput compared to Rotary Parlors. This system minimizes cow congestion, optimizes labor use, and supports higher daily milking capacity in dairy farming operations.

Robotic Rotary Platforms

Robotic rotary platforms in dairy farming offer efficient, continuous milking with automated cow identification, teat cleaning, and milking, optimizing labor and increasing throughput compared to traditional parallel parlors. These systems enhance cow comfort and milking consistency, resulting in improved milk quality and farm productivity while reducing labor costs and human error.

Real-Time Teat Identification

Rotary parlors offer continuous milking with integrated real-time teat identification systems that enhance individual cow monitoring and improve milking efficiency by reducing errors. Parallel parlors also support teat identification but typically process cows one at a time, making real-time data collection slower and less efficient compared to the streamlined workflow of rotary systems.

Cow Positioning Sensors

Cow positioning sensors in rotary parlors enable continuous monitoring of individual cows as they move through each milking station, optimizing milk yield and reducing stress by ensuring precise attachment timing. In contrast, parallel parlors use fixed-position sensors that detect cow alignment before milking, offering straightforward installation but limited real-time adjustment compared to rotary systems.

Split Rotary Decks

Split rotary decks in rotary parlors enhance milking efficiency by allowing continuous cow flow and simultaneous pre- and post-milking tasks, reducing stall turnover time compared to traditional parallel parlors that handle cows sequentially. This configuration optimizes labor use and cow comfort, significantly increasing throughput in high-volume dairy operations.

Smart Parlor Analytics

Rotary parlors optimize milking efficiency by continuously rotating cows through automated systems, enabling real-time data integration that enhances Smart Parlor Analytics for herd health and production monitoring. Parallel parlors provide fixed stalls for simultaneous milking, allowing detailed individual cow data collection, which supports advanced analytics for precise management decisions in dairy farming.

Rotary parlors vs Parallel parlors for milking systems Infographic

agridif.com

agridif.com