Controlled-atmosphere storage extends the shelf life of harvested fruits by precisely regulating oxygen, carbon dioxide, and humidity levels, slowing down respiration and delaying ripening processes. Refrigerated storage primarily reduces temperature to suppress microbial growth and metabolic activity but does not adjust gas composition, resulting in shorter preservation compared to controlled-atmosphere techniques. Optimal post-harvest management often combines these methods to maintain fruit quality, flavor, and nutritional value over extended periods.

Table of Comparison

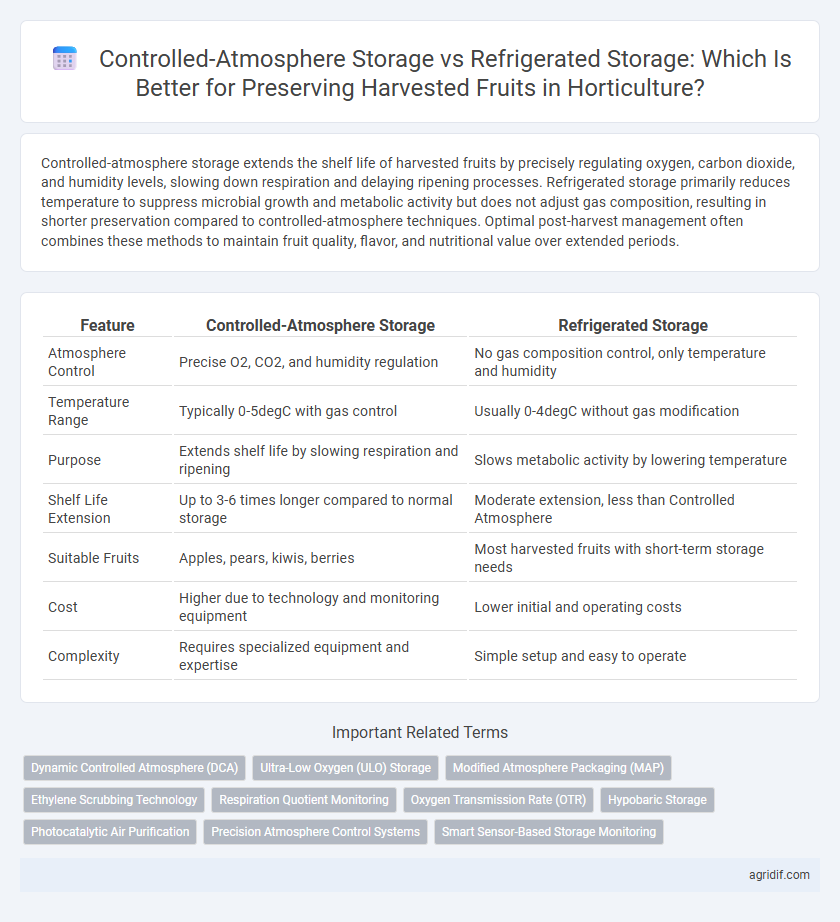

| Feature | Controlled-Atmosphere Storage | Refrigerated Storage |

|---|---|---|

| Atmosphere Control | Precise O2, CO2, and humidity regulation | No gas composition control, only temperature and humidity |

| Temperature Range | Typically 0-5degC with gas control | Usually 0-4degC without gas modification |

| Purpose | Extends shelf life by slowing respiration and ripening | Slows metabolic activity by lowering temperature |

| Shelf Life Extension | Up to 3-6 times longer compared to normal storage | Moderate extension, less than Controlled Atmosphere |

| Suitable Fruits | Apples, pears, kiwis, berries | Most harvested fruits with short-term storage needs |

| Cost | Higher due to technology and monitoring equipment | Lower initial and operating costs |

| Complexity | Requires specialized equipment and expertise | Simple setup and easy to operate |

Introduction to Postharvest Fruit Storage Methods

Controlled-atmosphere storage regulates oxygen, carbon dioxide, and humidity levels to slow fruit respiration and extend shelf life, proving effective for apples and pears. Refrigerated storage maintains low temperatures to reduce metabolic rates but does not alter atmospheric composition, suitable for a wide range of fruits with shorter storage requirements. Optimal postharvest fruit preservation depends on selecting the appropriate method based on fruit type, storage duration, and desired quality retention.

Principles of Controlled-Atmosphere Storage

Controlled-atmosphere (CA) storage maintains precise levels of oxygen, carbon dioxide, and humidity to slow the respiration rate and delay ripening of harvested fruits, significantly extending shelf life compared to conventional refrigerated storage. By reducing oxygen concentration typically to 1-3% and increasing carbon dioxide to 1-5%, CA storage creates a low-oxygen environment that inhibits ethylene production and microbial growth. This optimized gas composition coupled with temperature and humidity control preserves fruit firmness, flavor, and nutritional quality far beyond standard refrigeration methods.

Fundamentals of Refrigerated Storage Systems

Refrigerated storage systems maintain optimal temperature and humidity levels to slow down the metabolic processes and extend the shelf life of harvested fruits. These systems rely on vapor compression cycles, circulation fans, and precise temperature controls to create an environment that minimizes microbial growth and moisture loss. Proper insulation and humidity regulation in refrigerated storage prevent spoilage, preserving fruit quality and nutritional value during post-harvest handling.

Key Differences Between Controlled-Atmosphere and Refrigerated Storage

Controlled-atmosphere storage regulates oxygen, carbon dioxide, and humidity levels to slow fruit respiration and delay ripening, while refrigerated storage primarily lowers temperature to reduce metabolic activity. Controlled-atmosphere environments maintain specific gas concentrations, extending shelf life more effectively for sensitive fruits like apples and pears compared to standard refrigeration. Refrigerated storage is simpler and less costly but lacks the precision of gas control that helps prevent spoilage and preserves flavor, texture, and nutritional quality longer in controlled-atmosphere systems.

Impact on Fruit Shelf Life and Quality

Controlled-atmosphere storage extends harvested fruit shelf life by regulating oxygen, carbon dioxide, and humidity levels, which slows respiration and delays ripening, preserving firmness and nutritional quality. Refrigerated storage maintains low temperatures to reduce metabolic rate but does not modify gas composition, resulting in shorter shelf life compared to controlled-atmosphere systems. Studies on apples and pears show controlled-atmosphere storage can prolong shelf life by up to three times while maintaining superior texture and flavor retention.

Cost and Infrastructure Requirements

Controlled-atmosphere storage requires significant investment in sophisticated gas regulation and monitoring systems to maintain optimal oxygen and carbon dioxide levels, resulting in higher initial costs compared to refrigerated storage. Refrigerated storage relies primarily on temperature control with simpler infrastructure, making it more accessible and cost-effective for small to medium-scale operations. However, the enhanced preservation capabilities of controlled-atmosphere storage can justify its higher cost in large-scale commercial horticulture by reducing spoilage and extending fruit shelf life.

Effects on Nutritional Value and Sensory Attributes

Controlled-atmosphere storage slows respiration rates and ethylene production in harvested fruits by maintaining low oxygen and elevated carbon dioxide levels, effectively preserving vitamins such as vitamin C and retaining firmness, color, and flavor for extended periods. Refrigerated storage primarily reduces fruit temperature to slow metabolic processes but may cause moisture loss and firmness decline, potentially leading to diminished sensory attributes over time. Comparative studies show controlled-atmosphere storage better maintains antioxidant levels and sensory quality, especially in apples and pears, resulting in superior nutritional and organoleptic retention during prolonged storage.

Suitability for Different Types of Fruits

Controlled-atmosphere storage is ideal for long-term preservation of high-respiration fruits such as apples, pears, and kiwifruit, as it regulates oxygen, carbon dioxide, and humidity levels to slow ripening. Refrigerated storage suits short-term storage of berries, grapes, and stone fruits like peaches and cherries by maintaining low temperatures to reduce metabolic rates without modifying atmospheric gases. Each method optimizes shelf life by aligning storage conditions with the specific physiological requirements and sensitivity of different fruit types.

Environmental and Energy Considerations

Controlled-atmosphere storage maintains specific gas compositions to slow fruit respiration, which significantly reduces energy consumption compared to traditional refrigerated storage that relies solely on low temperatures. This method lowers carbon emissions by minimizing the frequent operation of cooling equipment and optimizing energy use through precise environmental control. Consequently, controlled-atmosphere storage offers a more sustainable solution by balancing energy efficiency with effective preservation of harvested fruits.

Recommendations for Optimal Storage Practices

For optimal storage of harvested fruits, Controlled-Atmosphere (CA) storage is recommended for extending shelf life by precisely regulating oxygen, carbon dioxide, and humidity levels to slow respiration and delay ripening. Refrigerated storage is effective for short-term preservation, maintaining low temperatures to reduce metabolic activity but lacks the advanced gas control of CA storage. Combining CA storage with consistent temperature and humidity monitoring ensures maximum freshness and quality retention for sensitive fruit varieties.

Related Important Terms

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) storage for harvested fruits provides precise regulation of oxygen and carbon dioxide levels, significantly slowing respiration and extending shelf life compared to traditional refrigerated storage methods. This advanced technique maintains optimal fruit quality by continuously monitoring and adjusting atmospheric conditions, reducing spoilage and preserving nutritional value more effectively than standard refrigeration.

Ultra-Low Oxygen (ULO) Storage

Ultra-Low Oxygen (ULO) storage, a cutting-edge form of controlled-atmosphere storage, optimizes oxygen levels to as low as 1-2%, significantly slowing fruit respiration and extending shelf life beyond traditional refrigerated storage by reducing ethylene production and delaying ripening. This method maintains superior fruit quality and firmness, making it essential for high-value crops like apples and pears where prolonged storage and minimal quality loss are critical.

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) enhances fruit preservation by regulating oxygen and carbon dioxide levels, reducing respiration rates more effectively than traditional refrigerated storage alone. Controlled-Atmosphere Storage (CAS) complements MAP by precisely adjusting atmospheric gases in large-scale facilities, extending shelf life while maintaining fruit quality post-harvest.

Ethylene Scrubbing Technology

Controlled-atmosphere storage utilizes ethylene scrubbing technology to actively remove ethylene gas, significantly slowing fruit ripening and extending shelf life compared to traditional refrigerated storage that primarily relies on temperature control. Ethylene scrubbers maintain optimal atmospheric conditions by reducing ethylene concentration, thereby preserving fruit firmness, color, and nutritional quality during long-term storage.

Respiration Quotient Monitoring

Controlled-atmosphere storage significantly enhances fruit preservation by optimizing oxygen and carbon dioxide levels, enabling precise Respiration Quotient (RQ) monitoring that indicates metabolic changes and delays ripening. Refrigerated storage primarily slows respiration through temperature reduction but lacks the dynamic gas composition control and real-time RQ data essential for extending shelf life and maintaining fruit quality.

Oxygen Transmission Rate (OTR)

Controlled-atmosphere storage maintains optimal oxygen levels by utilizing materials with low Oxygen Transmission Rate (OTR) to slow respiration and delay fruit ripening, enhancing shelf life and quality compared to refrigerated storage. Refrigerated storage alone relies on temperature reduction but often uses packaging with higher OTR, leading to faster oxygen ingress and less effective preservation of harvested fruits.

Hypobaric Storage

Hypobaric storage, a subset of controlled-atmosphere storage, maintains reduced atmospheric pressure to slow respiration rates and delay ripening in harvested fruits more effectively than conventional refrigerated storage, which primarily controls temperature and humidity. This technology enhances shelf life and preserves fruit quality by minimizing oxygen levels and reducing ethylene production, outperforming standard refrigerated storage in maintaining firmness and nutritional value.

Photocatalytic Air Purification

Controlled-atmosphere storage significantly extends the shelf life of harvested fruits by regulating oxygen and carbon dioxide levels, while photocatalytic air purification enhances this environment by degrading ethylene and microbial contaminants, thus reducing spoilage. Unlike refrigerated storage, which primarily lowers temperature to slow decay, combining controlled-atmosphere conditions with photocatalytic purification optimizes fruit preservation through improved air quality and oxidative stress reduction.

Precision Atmosphere Control Systems

Precision Atmosphere Control Systems in Controlled-Atmosphere Storage optimize oxygen, carbon dioxide, and humidity levels to significantly extend shelf life and maintain fruit quality compared to traditional Refrigerated Storage, which primarily relies on temperature regulation. These advanced systems reduce respiratory rates and delay ripening by continuously monitoring and adjusting gas compositions, enhancing post-harvest preservation and minimizing spoilage in harvested fruits.

Smart Sensor-Based Storage Monitoring

Smart sensor-based storage monitoring enhances controlled-atmosphere storage by precisely regulating oxygen, carbon dioxide, and humidity levels to extend the shelf life of harvested fruits while minimizing spoilage. In contrast, refrigerated storage primarily maintains low temperatures but often lacks real-time atmospheric control, making it less effective in preventing quality degradation during long-term fruit storage.

Controlled-Atmosphere Storage vs Refrigerated Storage for harvested fruits Infographic

agridif.com

agridif.com