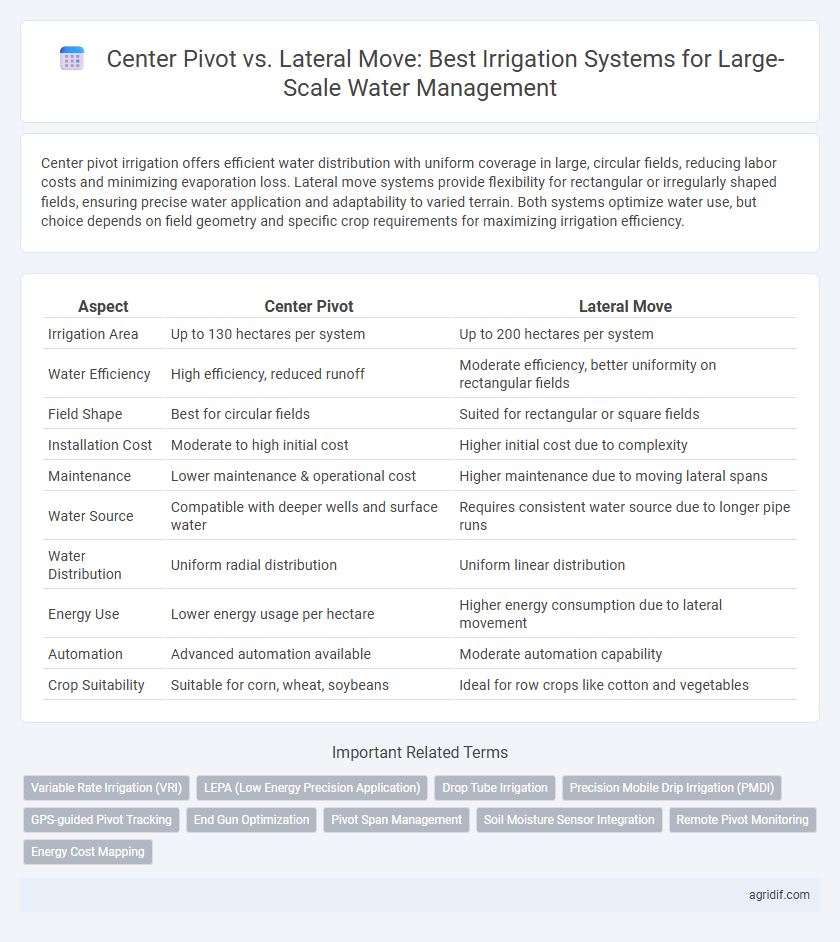

Center pivot irrigation offers efficient water distribution with uniform coverage in large, circular fields, reducing labor costs and minimizing evaporation loss. Lateral move systems provide flexibility for rectangular or irregularly shaped fields, ensuring precise water application and adaptability to varied terrain. Both systems optimize water use, but choice depends on field geometry and specific crop requirements for maximizing irrigation efficiency.

Table of Comparison

| Aspect | Center Pivot | Lateral Move |

|---|---|---|

| Irrigation Area | Up to 130 hectares per system | Up to 200 hectares per system |

| Water Efficiency | High efficiency, reduced runoff | Moderate efficiency, better uniformity on rectangular fields |

| Field Shape | Best for circular fields | Suited for rectangular or square fields |

| Installation Cost | Moderate to high initial cost | Higher initial cost due to complexity |

| Maintenance | Lower maintenance & operational cost | Higher maintenance due to moving lateral spans |

| Water Source | Compatible with deeper wells and surface water | Requires consistent water source due to longer pipe runs |

| Water Distribution | Uniform radial distribution | Uniform linear distribution |

| Energy Use | Lower energy usage per hectare | Higher energy consumption due to lateral movement |

| Automation | Advanced automation available | Moderate automation capability |

| Crop Suitability | Suitable for corn, wheat, soybeans | Ideal for row crops like cotton and vegetables |

Overview of Center Pivot and Lateral Move Irrigation Systems

Center pivot irrigation systems consist of a rotating sprinkler arm anchored at the center, delivering water uniformly across circular fields and offering efficient water use with minimal labor. Lateral move systems feature a linear, movable sprinkler structure that irrigates rectangular fields, providing precise water application and flexibility in field shapes. Both systems rely on automation and advanced controls to optimize water distribution, reduce runoff, and enhance crop yield in large-scale agricultural operations.

Design and Operational Differences

Center pivot irrigation systems feature a circular design with a central pivot point, enabling water application in a rotating pattern ideal for uniform coverage in large fields, while lateral move systems use a straight, linear structure that traverses across rectangular plots for more controlled water distribution. Center pivots often require less labor and are easier to automate due to their fixed pivot point and consistent circular path, whereas lateral move systems demand more complex controls and adjustments to manage linear movement and nozzle positioning. Operationally, center pivots tend to minimize water runoff through precise pressure and sprinkler spacing, whereas lateral moves allow for targeted irrigation zones, reducing water usage in specific crop areas but involving higher energy consumption for linear repositioning.

Water Distribution Efficiency Comparison

Center pivot irrigation systems generally exhibit higher water distribution efficiency, typically ranging from 85% to 90%, compared to lateral move systems, which average around 75% to 85%. The circular movement of center pivots reduces overlap and runoff, optimizing uniform water application and minimizing evaporation losses. Lateral move systems, while effective for rectangular fields, often face challenges with edge areas and uneven terrain, leading to less consistent water distribution and increased potential for water wastage.

Installation and Infrastructure Requirements

Center pivot irrigation systems require a central pivot point and a circular field design, with a fixed tower supporting the irrigation arm, demanding precise installation of electrical and mechanical components. Lateral move systems operate on rails across rectangular fields, necessitating robust infrastructure for continuous movement and track alignment. Both systems involve significant initial investment in land preparation, water source connection, and automation controls to ensure efficient and uniform water distribution.

Suitability for Various Crop Types and Field Shapes

Center pivot irrigation offers excellent suitability for circular fields and crops such as corn, wheat, and soybeans, where uniform water distribution supports high yields. Lateral move systems excel in rectangular or irregularly shaped fields, accommodating diverse crops like vegetables, cotton, and orchards with more precise irrigation control along field edges. Field shape and crop water requirements play critical roles in choosing between these systems to optimize water use efficiency and crop productivity.

Energy Consumption and Operational Costs

Center pivot irrigation systems typically consume less energy per hectare due to their circular movement and efficient water distribution, whereas lateral move systems often require higher energy input for linear coverage and repetitive repositioning. Operational costs for center pivots are generally lower, driven by reduced labor needs and maintenance simplicity compared to the more complex lateral move mechanisms. Energy consumption and maintenance on pumps also favor center pivots due to their optimized pressure and uniform coverage, making them more cost-effective for large-scale irrigation.

Maintenance and Longevity Considerations

Center pivot systems typically require less frequent maintenance due to their simpler design and fewer moving parts compared to lateral move systems, resulting in reduced downtime and operational costs. Lateral move systems, with extended pipelines and multiple moving joints, demand more rigorous inspections and repairs to prevent leaks and mechanical failures, potentially impacting their longevity. Proper maintenance practices, including regular lubrication, alignment checks, and timely part replacements, significantly enhance the lifespan of both irrigation systems in large-scale water management projects.

Automation and Technological Integration

Center pivot irrigation systems offer advanced automation capabilities with programmable controls, GPS-guided positioning, and real-time moisture sensors, enhancing water use efficiency on large-scale farms. Lateral move systems integrate automation through variable-rate irrigation technology and remote monitoring, enabling precise water application across rectangular fields. Both systems leverage IoT and AI-driven analytics to optimize irrigation scheduling, but center pivots generally provide superior adaptability in automation for circular cropping zones.

Environmental Impact and Water Conservation

Center pivot irrigation systems typically use less water due to their circular application pattern and precise control, reducing runoff and evaporation compared to lateral move systems. Lateral move irrigation covers larger rectangular areas but often results in higher water loss through evaporation and uneven distribution, increasing environmental stress. Choosing center pivot technology enhances water conservation efforts and minimizes soil erosion, supporting sustainable large-scale agriculture.

Choosing the Right System for Large-Scale Farms

Center pivot irrigation systems offer uniform water distribution with efficient energy use, making them ideal for circular large-scale fields, while lateral move systems provide adaptable linear coverage suited for rectangular plots. Selecting the right irrigation system depends on field shape, crop type, water availability, and topography to optimize water efficiency and reduce operational costs. Integrating soil moisture sensors and smart control technologies enhances precision irrigation, improving crop yield and sustainability in large-scale farm management.

Related Important Terms

Variable Rate Irrigation (VRI)

Center pivot irrigation systems equipped with Variable Rate Irrigation (VRI) technology enable precise water application tailored to soil variability, enhancing water use efficiency on large-scale farms compared to lateral move systems. VRI integration in center pivots allows for adjustable irrigation patterns across different zones, optimizing crop yields while minimizing water waste and energy consumption.

LEPA (Low Energy Precision Application)

Center pivot irrigation with LEPA technology offers superior water-use efficiency by delivering water directly to the crop root zone using low-pressure, low-energy sprinklers, reducing evaporation and runoff compared to lateral move systems. Large-scale farms benefit from center pivot LEPA systems through uniform water distribution, energy savings, and enhanced crop yields in water-scarce regions.

Drop Tube Irrigation

Center pivot irrigation with drop tube technology offers precise water delivery directly to the root zone, reducing evaporation and runoff compared to lateral move systems. This method enhances water use efficiency on large-scale farms by ensuring uniform distribution and minimizing water waste in irrigation management.

Precision Mobile Drip Irrigation (PMDI)

Center pivot irrigation offers efficient water distribution over circular fields, while lateral move systems provide rectangular coverage but with higher energy consumption; Precision Mobile Drip Irrigation (PMDI) integrates mobile drip lines with lateral or pivot systems to enhance water-use efficiency and reduce evaporation losses by delivering targeted irrigation at the root zone in large-scale farming. PMDI significantly improves precision in water management, lowers operational costs, and promotes sustainable agriculture through optimized nutrient application and minimized runoff.

GPS-guided Pivot Tracking

GPS-guided pivot tracking in center pivot irrigation systems enhances precision by enabling real-time alignment and automated course correction, reducing water waste and increasing crop uniformity compared to lateral move systems. Large-scale irrigation benefits from this technology as it maximizes field coverage and operational efficiency, optimizing water distribution while minimizing labor and maintenance costs.

End Gun Optimization

Center pivot irrigation systems equipped with optimized end guns enhance water distribution uniformity at the pivot outer edges, reducing water waste and improving crop yield efficiency on large-scale farms. Lateral move systems typically lack end guns, resulting in less precise edge watering and potential over-irrigation, which makes end gun optimization critical for maximizing irrigation efficiency in center pivots.

Pivot Span Management

Center pivot irrigation offers precise pivot span management through automated controls that adjust water distribution uniformly across large circular fields, optimizing water use efficiency and reducing waste. Lateral move systems cover rectangular areas but face challenges in pivot span regulation, often requiring manual adjustments, which can lead to uneven irrigation and increased water consumption.

Soil Moisture Sensor Integration

Center pivot irrigation systems integrated with soil moisture sensors enable precise water application by continuously monitoring soil conditions and adjusting irrigation schedules, optimizing water use efficiency over large fields. In contrast, lateral move systems with sensor integration provide targeted moisture data across rectangular plots, enhancing uniformity in water distribution but often requiring more complex calibration for variable soil types.

Remote Pivot Monitoring

Center pivot irrigation offers superior efficiency for large-scale water management by evenly distributing water in a circular pattern, while remote pivot monitoring enhances precision through real-time data on soil moisture, weather, and system performance. Lateral move systems provide rectangular coverage but rely heavily on manual adjustments, making remote monitoring integration crucial for optimizing water use and reducing operational costs.

Energy Cost Mapping

Center pivot systems typically consume less energy per hectare than lateral move systems due to their circular coverage and efficient water application, resulting in lower operational costs on large-scale farms. Energy cost mapping reveals that center pivots optimize pump usage and reduce fuel consumption by concentrating irrigation within a fixed radius, whereas lateral moves require more extensive pipe movement and higher energy inputs for uniform coverage.

Center pivot vs Lateral move for large-scale irrigation Infographic

agridif.com

agridif.com