Central pivot irrigation systems offer efficient water distribution for large, circular fields with uniform crop growth, while linear move systems provide greater flexibility for rectangular or irregularly shaped fields. Central pivots tend to be more cost-effective with lower labor demands, whereas linear moves enable more precise water application across diverse terrain and field conditions. Selecting between these systems depends on field shape, topography, crop types, and water availability to optimize irrigation efficiency and crop yield.

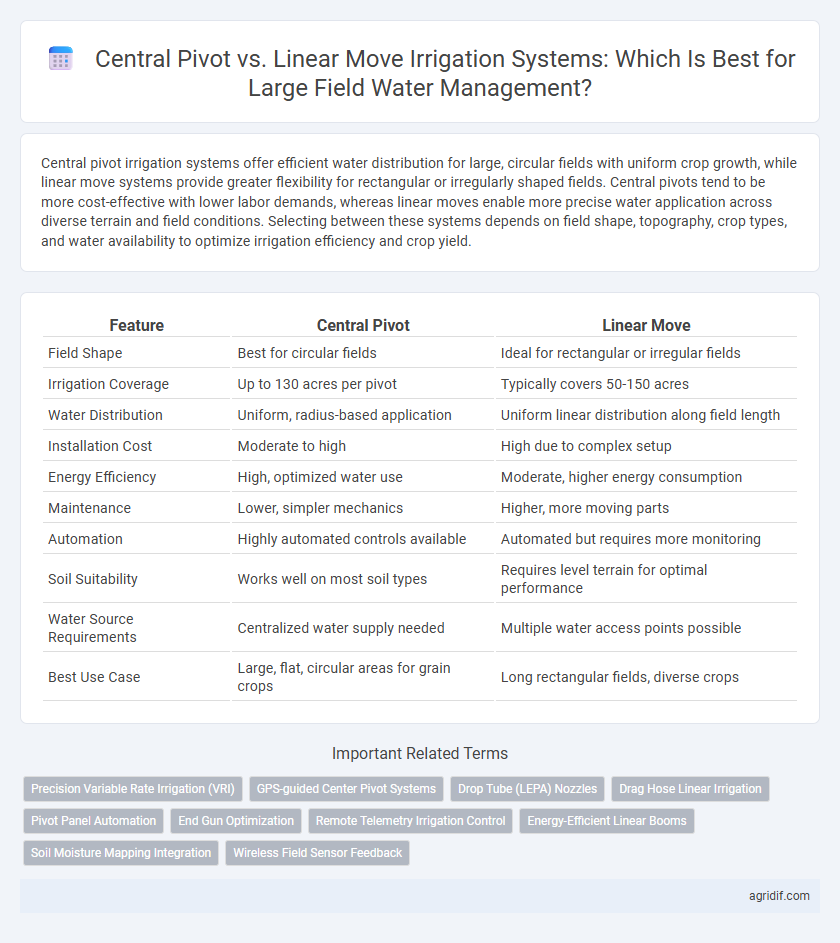

Table of Comparison

| Feature | Central Pivot | Linear Move |

|---|---|---|

| Field Shape | Best for circular fields | Ideal for rectangular or irregular fields |

| Irrigation Coverage | Up to 130 acres per pivot | Typically covers 50-150 acres |

| Water Distribution | Uniform, radius-based application | Uniform linear distribution along field length |

| Installation Cost | Moderate to high | High due to complex setup |

| Energy Efficiency | High, optimized water use | Moderate, higher energy consumption |

| Maintenance | Lower, simpler mechanics | Higher, more moving parts |

| Automation | Highly automated controls available | Automated but requires more monitoring |

| Soil Suitability | Works well on most soil types | Requires level terrain for optimal performance |

| Water Source Requirements | Centralized water supply needed | Multiple water access points possible |

| Best Use Case | Large, flat, circular areas for grain crops | Long rectangular fields, diverse crops |

Overview of Central Pivot and Linear Move Irrigation Systems

Central pivot and linear move irrigation systems are advanced mechanized solutions for large field irrigation, each optimizing water distribution with distinct movement patterns. Central pivot systems rotate around a fixed central point, enabling uniform water application in circular fields and reducing labor costs through automation. Linear move systems move linearly across rectangular fields, offering precise irrigation control and adaptability to field shapes while maintaining consistent water application efficiency.

Key Design Differences between Central Pivot and Linear Move

Central pivot irrigation features a system rotating around a fixed central point, delivering water in a circular pattern ideal for uniform coverage in large fields. Linear move systems travel in a straight line across rectangular fields, providing consistent watering in elongated crop layouts. Key design differences include pivot's fixed pivot point versus linear's continuous lateral movement, affecting water distribution patterns and suitability for varying field shapes.

Water Distribution Efficiency: Central Pivot vs Linear Move

Central pivot irrigation systems deliver water in a circular pattern, optimizing water distribution by reducing runoff and deep percolation, often achieving application efficiencies of 80-90%. In contrast, linear move systems irrigate rectangular fields with uniform water application, offering consistent coverage but potentially lower efficiency due to edge losses and overlapping zones. Selecting the appropriate system depends on field shape and crop requirements, with central pivot generally outperforming linear move in water distribution efficiency for large, irregular fields.

Suitability for Different Field Shapes and Sizes

Central pivot irrigation systems are highly suitable for large, circular fields, offering efficient water distribution with minimal labor but are less effective for irregular or rectangular field shapes. Linear move systems provide greater flexibility for rectangular or irregularly shaped fields, ensuring even water application across varying field dimensions. Choosing between central pivot and linear move irrigation depends primarily on field geometry and size, with central pivots optimized for round areas and linear moves preferred for expansive, elongated fields.

Installation and Maintenance Requirements

Central pivot irrigation systems require a circular layout and involve installing a central pivot point with radial arms, making their setup complex but more automated. Linear move systems comprise a series of towers on tracks moving in straight lines, necessitating precise alignment and regular track maintenance to prevent operational issues. Maintenance for central pivots often focuses on the central pivot mechanism and sprinkler heads, while linear move systems demand consistent inspection of drive motors, tires, and track systems for efficient large field irrigation.

Energy Consumption and Operational Costs

Central pivot irrigation systems generally consume less energy per hectare due to their circular coverage and more efficient water application technology, reducing operational costs significantly for large fields. Linear move systems, while providing uniform irrigation over rectangular fields, often require more pumping energy and increased labor, leading to higher energy consumption and operational expenses. Choosing between the two depends on field shape and size, but energy efficiency and cost-effectiveness typically favor central pivot systems in large-scale irrigation projects.

Impact on Crop Yield and Soil Health

Central pivot irrigation provides uniform water distribution, promoting consistent crop yield across large fields, while linear move systems allow for targeted irrigation in irregularly shaped areas, optimizing water use efficiency. Central pivots often reduce soil compaction and erosion due to fewer wheeltracks compared to linear moves, enhancing long-term soil health. Crop yield benefits from central pivots are typically higher in fields with flat topography, whereas linear moves adapt better to variations, supporting soil structure preservation and sustainable water management.

Adaptability to Various Crops and Terrains

Central pivot irrigation offers superior adaptability across diverse crop types and uneven terrains due to its circular watering pattern and adjustable nozzle height, making it ideal for irregularly shaped fields. Linear move systems, while efficient for rectangular fields, have limited flexibility in crop variety and struggle with uneven topography, restricting their use primarily to flat landscapes. Choosing between these systems depends on field shape, crop diversity, and terrain variability, with central pivots generally providing greater versatility in large-scale irrigation management.

Technological Integration and Automation Potential

Central pivot irrigation systems offer advanced technological integration with automated control of water application, GPS-guided positioning, and real-time soil moisture monitoring, optimizing water use efficiency in large fields. Linear move systems also support automation but typically require more manual adjustments during operation, limiting their full potential for seamless integration with precision agriculture tools. Both systems benefit from IoT sensors and remote management platforms, yet central pivots generally provide higher scalability and ease of data-driven irrigation scheduling.

Long-Term Cost-Benefit Analysis for Large Farms

Central pivot irrigation systems typically offer lower installation and maintenance costs compared to linear move systems, making them more cost-effective for large, circular fields. Linear move irrigation provides more uniform water distribution over rectangular fields but requires higher energy consumption and increased labor over time. Long-term cost-benefit analysis favors central pivots for most large farms due to greater water-use efficiency, reduced operational expenses, and lower depreciation rates.

Related Important Terms

Precision Variable Rate Irrigation (VRI)

Central pivot irrigation systems offer superior Precision Variable Rate Irrigation (VRI) capabilities due to their circular coverage and advanced sensor integration, enabling precise water application tailored to soil variability across large fields. Linear move systems provide consistent, uniform irrigation over rectangular plots but typically lack the fine-tuned VRI precision achievable with central pivots, making them less efficient for site-specific water management in heterogeneous fields.

GPS-guided Center Pivot Systems

GPS-guided center pivot systems enhance irrigation efficiency on large fields by enabling precise water application through automated, circular coverage, reducing overlap and water waste compared to linear move systems that follow straight paths. These advanced pivots optimize crop yield by utilizing real-time positioning data to adjust water distribution accurately, ensuring uniform soil moisture across expansive agricultural lands.

Drop Tube (LEPA) Nozzles

Central pivot irrigation systems equipped with Drop Tube (LEPA) nozzles deliver water directly to the soil surface, minimizing evaporation and wind drift losses, making them highly efficient for large, circular fields. In contrast, linear move systems with LEPA nozzles provide uniform water application across rectangular fields but may face challenges in maintaining consistent low-energy precision application due to variable hose height and field topography.

Drag Hose Linear Irrigation

Drag hose linear irrigation systems offer precise water application and reduced soil compaction in large-scale fields compared to central pivot systems, enhancing crop uniformity and minimizing water waste. Their adaptability to uneven terrain and efficient energy use make drag hose linear irrigation a cost-effective solution for optimizing water management in expansive agricultural areas.

Pivot Panel Automation

Central pivot irrigation systems with advanced pivot panel automation enable precise water application and real-time adjustments for large fields, enhancing water efficiency and crop yield. Compared to linear move systems, automated pivot panels provide streamlined control, reducing labor costs and minimizing water waste through targeted irrigation management.

End Gun Optimization

Central pivot systems equipped with advanced end gun optimization deliver precise water distribution at field edges, reducing runoff and enhancing uniformity compared to linear move systems. End gun technology in central pivots maximizes irrigation efficiency by targeting hard-to-reach areas, improving crop yield and conserving water in large-scale agricultural operations.

Remote Telemetry Irrigation Control

Central pivot irrigation systems offer superior remote telemetry irrigation control by enabling precise, automated water application through centralized sensors and control units, enhancing efficiency in large fields. Linear move systems, while effective for uniform water distribution, often require more complex telemetry setups for remote monitoring and control over extended field areas, impacting operational scalability.

Energy-Efficient Linear Booms

Linear move irrigation systems with energy-efficient linear booms optimize water distribution across large fields by reducing energy consumption through precise, low-friction movement mechanisms and advanced sprinkler placements. Compared to central pivot systems, these linear boom systems enable more uniform irrigation coverage and enhanced energy savings, making them suitable for rectangular or irregular field shapes.

Soil Moisture Mapping Integration

Central pivot irrigation systems provide uniform water application with advanced soil moisture mapping integration, enabling precise adjustments based on real-time soil moisture data to optimize crop yield and water efficiency. Linear move systems cover rectangular fields effectively and incorporate soil moisture sensors for targeted irrigation, reducing water waste and enhancing irrigation scheduling accuracy in large-scale agricultural operations.

Wireless Field Sensor Feedback

Central pivot irrigation systems often integrate wireless field sensor feedback to precisely monitor soil moisture and optimize water distribution across circular fields, enhancing water-use efficiency. Linear move systems with wireless sensors provide uniform irrigation for rectangular fields by adjusting water application based on real-time soil and crop data, reducing wastage and improving crop yield.

Central pivot vs Linear move for large field irrigation Infographic

agridif.com

agridif.com