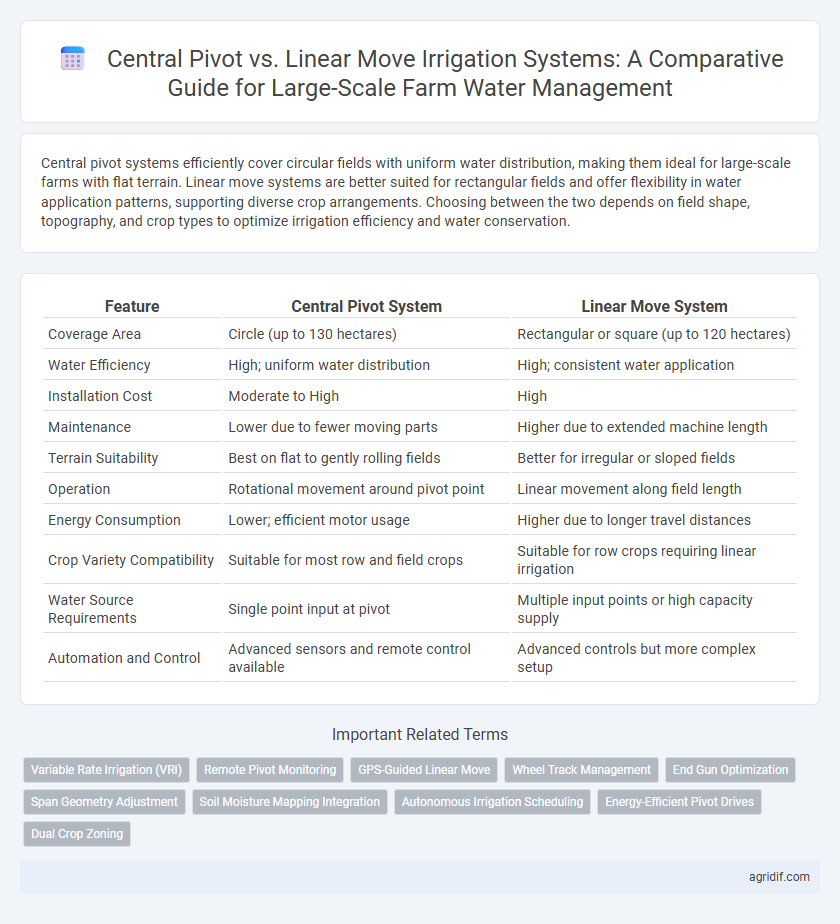

Central pivot systems efficiently cover circular fields with uniform water distribution, making them ideal for large-scale farms with flat terrain. Linear move systems are better suited for rectangular fields and offer flexibility in water application patterns, supporting diverse crop arrangements. Choosing between the two depends on field shape, topography, and crop types to optimize irrigation efficiency and water conservation.

Table of Comparison

| Feature | Central Pivot System | Linear Move System |

|---|---|---|

| Coverage Area | Circle (up to 130 hectares) | Rectangular or square (up to 120 hectares) |

| Water Efficiency | High; uniform water distribution | High; consistent water application |

| Installation Cost | Moderate to High | High |

| Maintenance | Lower due to fewer moving parts | Higher due to extended machine length |

| Terrain Suitability | Best on flat to gently rolling fields | Better for irregular or sloped fields |

| Operation | Rotational movement around pivot point | Linear movement along field length |

| Energy Consumption | Lower; efficient motor usage | Higher due to longer travel distances |

| Crop Variety Compatibility | Suitable for most row and field crops | Suitable for row crops requiring linear irrigation |

| Water Source Requirements | Single point input at pivot | Multiple input points or high capacity supply |

| Automation and Control | Advanced sensors and remote control available | Advanced controls but more complex setup |

Overview of Central Pivot and Linear Move Irrigation Systems

Central pivot irrigation systems consist of a rotating sprinkler mounted on wheeled towers that irrigate circular fields efficiently, optimizing water distribution and reducing labor costs. Linear move systems operate on a straight trajectory with sprinklers mounted on towers moving linearly across rectangular fields, providing uniform irrigation for large-scale crop production. Both systems use advanced technology such as GPS and variable rate irrigation to enhance water use efficiency and crop yields in extensive farming operations.

Key Components and Mechanisms of Each System

Central pivot irrigation systems feature a rotating arm anchored at a central pivot point, employing radial spans equipped with sprinklers that distribute water uniformly across circular fields. Linear move systems consist of a movable structure that travels in straight lines along a rectangular field, using towers mounted on wheels with sprinklers delivering water in a linear pattern. Key components of central pivot systems include the pivot point, radial pipes, and drive motors, while linear move systems rely on electric drives, span towers, and wheel assemblies for efficient water delivery over large, rectangular farm areas.

Water Efficiency and Distribution Uniformity

Central pivot irrigation systems deliver water in a circular pattern, providing high water efficiency by minimizing runoff and deep percolation, which is crucial for large-scale farms managing limited water resources. Linear move systems offer greater flexibility for rectangular fields and often achieve better distribution uniformity along their length, reducing water waste in irregularly shaped areas. Both systems optimize water use, but central pivot generally excels in water efficiency, while linear move enhances uniform irrigation distribution in large-scale agricultural operations.

Installation and Maintenance Requirements

Central pivot irrigation systems require more precise installation with a fixed central point and a radial arm, demanding professional setup and alignment to ensure uniform water distribution. Linear move systems involve tracks and movable spans that require extensive groundwork for installation and regular maintenance of wheels, drives, and guide systems to prevent operational disruptions. Both systems necessitate periodic inspections, but linear moves generally demand higher maintenance intensity due to their mechanical complexity and exposure to field conditions.

Cost Comparison: Initial Investment and Long-term Operation

Central pivot irrigation systems typically require a higher initial investment ranging from $50,000 to $100,000 per unit, but offer lower long-term operational costs due to efficient water distribution and reduced labor requirements. Linear move systems demand a more moderate upfront cost estimated between $30,000 and $70,000; however, they often incur higher maintenance expenses and increased water usage over time, raising overall operational costs. Large-scale farms prioritizing cost-efficiency tend to favor central pivots for sustainable water management and reduced energy consumption, despite the steeper initial capital outlay.

Suitability for Different Crop Types and Field Shapes

Central pivot irrigation systems are best suited for circular fields and crops like corn, wheat, and soybeans, benefiting from uniform watering in large, open areas. Linear move systems excel in rectangular or irregularly shaped fields, providing precise irrigation for row crops such as vegetables and cotton, reducing water waste. Field shape and crop type critically influence the choice between central pivot and linear move irrigation for maximizing efficiency and uniform water distribution.

Technological Integration and Automation Capabilities

Central pivot irrigation systems incorporate advanced sensors and GPS technology to optimize water distribution, enabling precise control and automation tailored to crop needs on large-scale farms. Linear move systems offer modular automation with programmable zones, allowing efficient water management over rectangular fields but often require more manual oversight compared to central pivots. Both systems leverage IoT integration and data analytics to enhance irrigation efficiency, though central pivots typically provide higher degrees of automation and real-time adjustments.

Impact on Soil Health and Crop Yields

Central pivot irrigation systems provide uniform water distribution, promoting consistent soil moisture levels that enhance root development and increase crop yields on large-scale farms. Linear move systems offer precise water application across elongated fields, reducing soil erosion and minimizing nutrient runoff, which positively affects soil health. Both systems improve water use efficiency, but central pivots tend to deliver slightly higher yield gains due to their circled coverage pattern optimizing soil moisture retention.

Energy Consumption and Sustainability Considerations

Central pivot irrigation systems typically consume less energy per hectare compared to linear move systems due to their circular coverage and efficient water application techniques. Linear move systems, while offering more uniform coverage across rectangular fields, often require higher energy inputs for frequent repositioning and longer pipeline runs. Sustainability considerations favor central pivot systems for their potential to reduce water waste and lower carbon footprints in large-scale farming operations.

Decision Factors: Choosing the Best System for Your Farm

Central pivot irrigation systems offer efficient coverage for circular fields, minimizing water wastage with precise application and are ideal for farms with uniform topography. Linear move systems provide flexibility for rectangular or irregularly shaped fields, enabling consistent water distribution across long distances but may incur higher energy costs due to their mobility. Key decision factors include farm shape, soil type, water source availability, energy consumption, and cost-effectiveness to ensure optimal irrigation management and crop yield.

Related Important Terms

Variable Rate Irrigation (VRI)

Central pivot and linear move irrigation systems both support Variable Rate Irrigation (VRI) technology, enabling precise water application that adapts to spatial variability in large-scale farms. Central pivots typically offer greater flexibility in implementing VRI due to their circular coverage patterns, while linear moves provide uniform distribution across rectangular fields, optimizing water efficiency and crop yield based on soil and crop variability data.

Remote Pivot Monitoring

Central pivot irrigation systems equipped with remote pivot monitoring enable real-time data collection and precise water application, enhancing efficiency and reducing water waste on large-scale farms. Linear move systems, while effective for rectangular fields, generally lack the advanced remote monitoring capabilities that central pivots offer, limiting their ability to optimize water management remotely.

GPS-Guided Linear Move

GPS-guided linear move irrigation systems enhance water efficiency and uniformity by precisely controlling application rates across large-scale farms, reducing overlap and runoff compared to central pivot systems. These systems optimize water distribution on rectangular fields, improving crop yield and conserving resources through targeted irrigation that adapts to field topography and soil variability.

Wheel Track Management

Central pivot irrigation offers efficient wheel track management by minimizing soil compaction through uniform circular movement and consistent wheel spacing, enhancing water distribution and crop yield on large-scale farms. In contrast, linear move systems require careful wheel track planning to prevent soil damage and ensure even irrigation across rectangular fields, often necessitating advanced technology to optimize track patterns and reduce machine-induced soil stress.

End Gun Optimization

Central pivot systems with optimized end guns enhance water distribution uniformity on large-scale farms, reducing runoff and improving irrigation efficiency compared to linear move systems. End gun technology in central pivots allows precise water application at field edges, maximizing crop yield and conserving water resources.

Span Geometry Adjustment

Central pivot irrigation systems feature a fixed center with rotating spans capable of precise geometry adjustments to optimize water distribution across circular fields. Linear move systems utilize adjustable spans to cover rectangular areas but offer less flexibility in span geometry modification, impacting uniform water application on large-scale farms.

Soil Moisture Mapping Integration

Central pivot irrigation systems offer efficient water distribution with uniform soil moisture levels, while linear move systems provide enhanced flexibility in soil moisture mapping integration, allowing precise application of water based on spatial variability. Advanced soil moisture sensors and remote sensing technology enable both systems to optimize irrigation scheduling, reduce water waste, and improve crop yields on large-scale farms.

Autonomous Irrigation Scheduling

Central pivot systems offer precise autonomous irrigation scheduling by leveraging advanced sensors and GPS technology to optimize water application over large circular fields, minimizing wastage and enhancing crop yield. Linear move systems enable consistent, scalable irrigation across rectangular plots with automated scheduling algorithms that adjust water distribution based on real-time soil moisture data and crop requirements.

Energy-Efficient Pivot Drives

Central pivot systems with energy-efficient pivot drives reduce power consumption by optimizing torque distribution and minimizing friction losses, making them more cost-effective for large-scale farms compared to linear move systems. These advanced drive technologies enhance irrigation uniformity and operational precision while significantly lowering energy expenses and environmental impact.

Dual Crop Zoning

Central pivot systems optimize water distribution by enabling circular irrigation patterns ideal for uniform crop zones, while linear move systems facilitate Dual Crop Zoning by allowing precise, rectangular irrigation tailored to distinct crops in segmented field areas. Dual Crop Zoning enhances resource efficiency and yield by matching irrigation schedules and water volumes to specific crop needs within large-scale farms, leveraging the spatial flexibility of linear move systems compared to central pivots.

Central pivot vs Linear move system for large-scale farms Infographic

agridif.com

agridif.com