Gravity-fed irrigation systems use natural elevation differences to deliver water efficiently, reducing energy costs and maintenance requirements. Pump-fed systems provide greater control over water pressure and distribution, allowing precise irrigation in varied terrains and larger agricultural areas. Choosing between these systems depends on factors such as topography, water availability, and crop water needs, optimizing water use efficiency and sustainability.

Table of Comparison

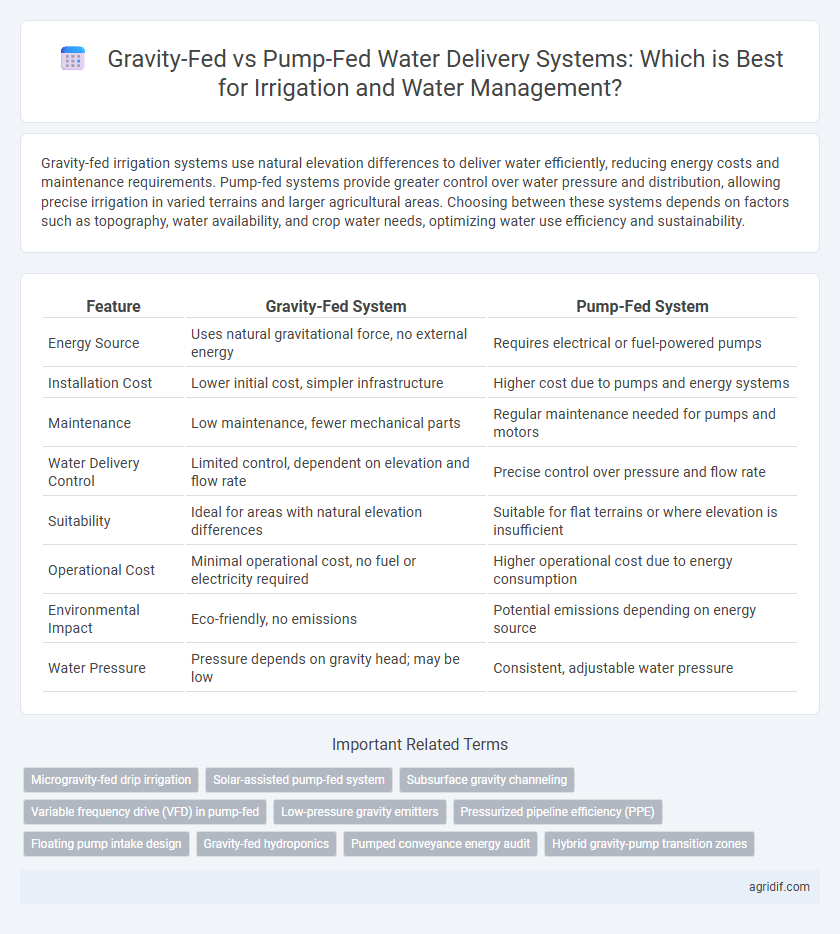

| Feature | Gravity-Fed System | Pump-Fed System |

|---|---|---|

| Energy Source | Uses natural gravitational force, no external energy | Requires electrical or fuel-powered pumps |

| Installation Cost | Lower initial cost, simpler infrastructure | Higher cost due to pumps and energy systems |

| Maintenance | Low maintenance, fewer mechanical parts | Regular maintenance needed for pumps and motors |

| Water Delivery Control | Limited control, dependent on elevation and flow rate | Precise control over pressure and flow rate |

| Suitability | Ideal for areas with natural elevation differences | Suitable for flat terrains or where elevation is insufficient |

| Operational Cost | Minimal operational cost, no fuel or electricity required | Higher operational cost due to energy consumption |

| Environmental Impact | Eco-friendly, no emissions | Potential emissions depending on energy source |

| Water Pressure | Pressure depends on gravity head; may be low | Consistent, adjustable water pressure |

Introduction to Irrigation Water Delivery Methods

Gravity-fed irrigation systems rely on natural elevation differences to distribute water efficiently, minimizing energy consumption and operational costs. Pump-fed systems use mechanical pumps to deliver water, enabling precise control over flow rates and allowing irrigation in areas without natural water sources or uneven terrain. Selection between these methods depends on factors such as topography, water availability, energy resources, and crop requirements in water management planning.

Overview of Gravity-Fed Systems

Gravity-fed irrigation systems utilize the natural flow of water from elevated sources, such as reservoirs or rivers, delivering water without the need for mechanical pumps. These systems are energy-efficient, low-cost, and require minimal maintenance, making them ideal for regions with suitable topography. Their efficiency depends on accurate channel design and slope management to ensure uniform water distribution across agricultural fields.

Overview of Pump-Fed Systems

Pump-fed systems use mechanical energy to move water from sources like wells, rivers, or reservoirs to irrigation fields, offering precise control over water flow and pressure. These systems enable irrigation across varying terrains, making them suitable for uneven or elevated landscapes where gravity-fed methods fail. Energy consumption and maintenance costs are key considerations, but their adaptability supports efficient water management in diverse agricultural settings.

Installation Requirements and Infrastructure

Gravity-fed irrigation systems require minimal installation infrastructure, relying primarily on natural land slope and simple channels or pipes to deliver water, resulting in lower initial costs and reduced maintenance needs. In contrast, pump-fed systems demand significant infrastructure, including pumps, power sources, and reinforced pipelines, which increase installation complexity and capital investment. Proper site assessment ensures gravity-fed systems optimize terrain advantages, while pump-fed setups require engineered designs to handle pressure and flow rates effectively.

Energy Consumption and Operational Costs

Gravity-fed irrigation systems consume minimal energy as they rely on natural water flow, significantly reducing operational costs compared to pump-fed systems that depend on electricity or fuel to operate. Pump-fed systems incur higher energy consumption, leading to increased operational expenses for fuel or power maintenance, especially in large-scale agricultural applications. Selecting a gravity-fed system enhances sustainability by lowering carbon footprints and long-term expenditures in water delivery infrastructure.

Water Use Efficiency and Distribution Uniformity

Gravity-fed irrigation systems offer higher water use efficiency by minimizing energy consumption and reducing water loss through evaporation and runoff, ensuring sustainable water management practices. Pump-fed systems provide greater distribution uniformity, especially on uneven terrain, by enabling precise control over pressure and flow rates to match crop requirements. Selecting between gravity-fed and pump-fed systems depends on balancing water use efficiency and distribution uniformity based on topography and specific irrigation goals.

Suitability for Different Terrains and Crops

Gravity-fed irrigation systems excel in gently sloped or uneven terrains where natural water flow can be effectively harnessed, making them ideal for crops like rice, paddy, and vegetables requiring consistent moisture. Pump-fed systems offer greater flexibility and control, suitable for flat or hilly areas with limited natural water flow, supporting a variety of crops including orchards, row crops, and high-value horticulture. Selecting the appropriate system depends on terrain slope, water availability, and crop water requirements to maximize efficiency and yield.

Maintenance and System Longevity

Gravity-fed irrigation systems require minimal maintenance due to the absence of mechanical parts, resulting in lower operational costs and longer system longevity. Pump-fed systems demand regular inspection and servicing of pumps, motors, and electrical components to prevent breakdowns and extend lifespan. Efficient maintenance practices directly influence the durability and performance of both gravity-fed and pump-fed water delivery methods in irrigation management.

Environmental Impact and Sustainability

Gravity-fed irrigation systems significantly reduce energy consumption by relying on natural elevation differences, resulting in lower greenhouse gas emissions compared to pump-fed systems that depend on electricity or fossil fuels. These systems promote sustainability through reduced operational costs and minimal carbon footprint, enhancing water conservation by minimizing evaporation and runoff due to controlled flow rates. In contrast, pump-fed systems often contribute to soil degradation and water resource depletion due to higher energy use and less efficient water distribution, challenging long-term environmental sustainability.

Choosing the Right System: Key Decision Factors

Selecting the optimal irrigation system hinges on factors such as topography, water source availability, and energy costs. Gravity-fed systems excel in areas with natural elevation differences, providing cost-effective, energy-free water delivery, while pump-fed systems offer greater flexibility and control, especially in flat terrains or where water sources are limited. Assessing land slope, water demand, and budget constraints ensures efficient water management tailored to specific agricultural needs.

Related Important Terms

Microgravity-fed drip irrigation

Microgravity-fed drip irrigation systems utilize natural water flow with minimal energy consumption, optimizing water efficiency by delivering precise moisture directly to plant roots through low-pressure emitters. Compared to pump-fed systems, these setups reduce operational costs and maintenance while harnessing gravity to maintain consistent irrigation in sloped agricultural fields.

Solar-assisted pump-fed system

Solar-assisted pump-fed systems harness photovoltaic energy to efficiently deliver water, reducing reliance on grid electricity and fossil fuels. These systems offer precise control over irrigation schedules and water distribution, enhancing water management and crop yield compared to traditional gravity-fed methods.

Subsurface gravity channeling

Subsurface gravity channeling in irrigation utilizes natural land slope to deliver water efficiently without mechanical energy, reducing operational costs and minimizing energy consumption compared to pump-fed systems. This method enhances groundwater recharge and supports sustainable water management by maintaining soil moisture levels while preventing surface runoff and erosion.

Variable frequency drive (VFD) in pump-fed

Pump-fed irrigation systems equipped with Variable Frequency Drives (VFD) optimize water delivery by adjusting pump motor speed to match precise irrigation demands, significantly enhancing energy efficiency and reducing operational costs. In contrast to gravity-fed systems relying on natural elevation, VFD-controlled pumps provide consistent pressure and flow rates, enabling precise water management in diverse agricultural terrains.

Low-pressure gravity emitters

Low-pressure gravity emitters in gravity-fed irrigation systems provide energy-efficient water delivery by utilizing natural elevation differences, reducing operational costs and equipment maintenance. These systems offer sustainable water management solutions with improved uniformity and minimal energy consumption compared to pump-fed systems that rely on mechanical pressure and electricity.

Pressurized pipeline efficiency (PPE)

Gravity-fed systems typically demonstrate higher pressurized pipeline efficiency (PPE) due to minimal energy input as water flows naturally under the influence of gravity, reducing pressure losses and operational costs. In contrast, pump-fed systems often experience lower PPE because mechanical energy is required to maintain pressure, leading to energy consumption and potential pressure fluctuations along the pipeline.

Floating pump intake design

A floating pump intake design in pump-fed irrigation systems ensures consistent water extraction from varying water levels, reducing sediment intake and maintenance compared to fixed intakes typical in gravity-fed systems. This design enhances operational efficiency by adapting to fluctuating water sources, thereby optimizing water delivery and minimizing disruptions in irrigation schedules.

Gravity-fed hydroponics

Gravity-fed hydroponics systems use natural gravitational force to deliver nutrient solutions, reducing energy costs and simplifying setup compared to pump-fed systems reliant on electricity. These systems enhance water efficiency by minimizing mechanical failures and enabling consistent, low-pressure flow ideal for sustainable irrigation and water management in hydroponic agriculture.

Pumped conveyance energy audit

Pumped conveyance energy audits in irrigation systems focus on evaluating the efficiency of energy use in pump-fed water delivery, identifying losses in pump performance, pipeline friction, and operational practices to optimize energy consumption. Comparatively, pump-fed systems consume significant electrical or fuel energy, making energy audit insights essential for reducing operational costs and improving sustainability in water management.

Hybrid gravity-pump transition zones

Hybrid gravity-pump transition zones in irrigation optimize water delivery by combining the energy efficiency of gravity-fed systems with the reliability of pump-fed systems, enhancing operational flexibility across varying terrain elevations. This integration reduces energy consumption while maintaining consistent water pressure and flow, crucial for precise irrigation scheduling and sustainable water management.

Gravity-fed system vs Pump-fed system for water delivery Infographic

agridif.com

agridif.com