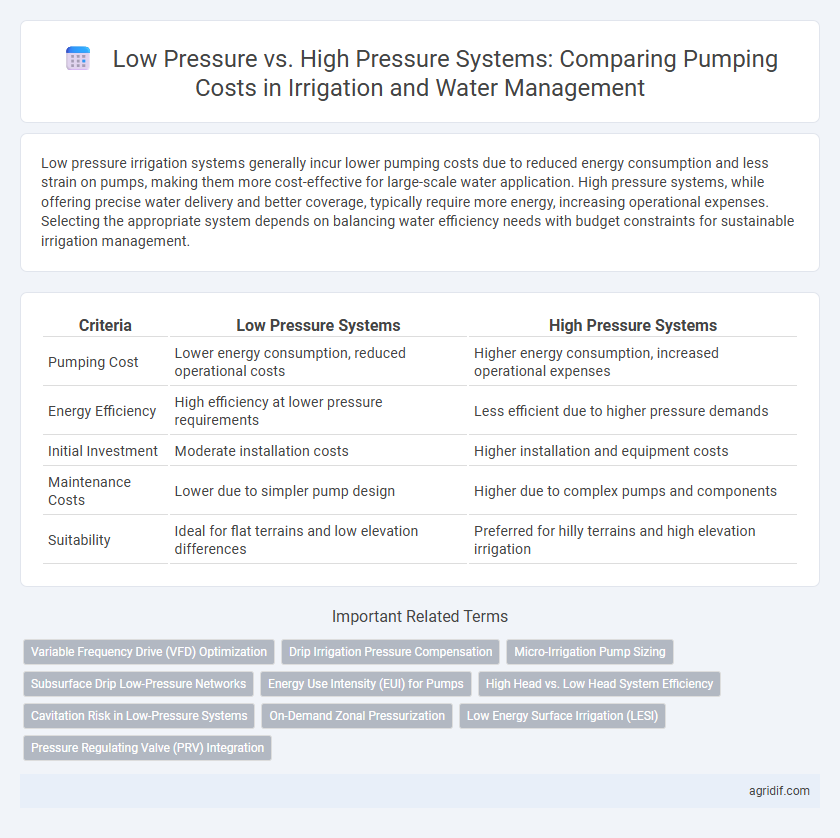

Low pressure irrigation systems generally incur lower pumping costs due to reduced energy consumption and less strain on pumps, making them more cost-effective for large-scale water application. High pressure systems, while offering precise water delivery and better coverage, typically require more energy, increasing operational expenses. Selecting the appropriate system depends on balancing water efficiency needs with budget constraints for sustainable irrigation management.

Table of Comparison

| Criteria | Low Pressure Systems | High Pressure Systems |

|---|---|---|

| Pumping Cost | Lower energy consumption, reduced operational costs | Higher energy consumption, increased operational expenses |

| Energy Efficiency | High efficiency at lower pressure requirements | Less efficient due to higher pressure demands |

| Initial Investment | Moderate installation costs | Higher installation and equipment costs |

| Maintenance Costs | Lower due to simpler pump design | Higher due to complex pumps and components |

| Suitability | Ideal for flat terrains and low elevation differences | Preferred for hilly terrains and high elevation irrigation |

Introduction to Irrigation Pumping Systems

Low pressure irrigation pumping systems typically consume less energy due to reduced friction losses and simpler design, resulting in lower operational costs compared to high pressure systems. High pressure systems require more powerful pumps to maintain elevated pressure levels, increasing electricity consumption and maintenance expenses. Evaluating site-specific factors such as water source, field topography, and crop type is crucial in selecting an efficient pumping system that balances initial investment with long-term cost savings.

Understanding Low Pressure Systems

Low pressure irrigation systems operate at lower energy levels, resulting in significantly reduced pumping costs compared to high pressure systems. These systems use larger diameter pipes and emitters designed to deliver water at low pressure, minimizing friction losses and energy consumption. Understanding the mechanics of low pressure systems is essential for optimizing energy efficiency and lowering operational expenses in irrigation water management.

Overview of High Pressure Systems

High pressure irrigation systems typically require more energy per unit of water pumped compared to low pressure systems, leading to higher operational costs. These systems are essential for applications requiring water to be delivered over long distances or elevated terrains, ensuring adequate pressure for efficient distribution. Optimizing pump efficiency and incorporating variable frequency drives can help mitigate the increased energy expenses associated with high pressure pumping systems.

Energy Consumption Comparison

Low pressure irrigation systems generally consume less energy than high pressure systems due to reduced friction losses and lower pump head requirements, resulting in lower operational pumping costs. High pressure systems demand more electricity to maintain increased flow rates and pressures, often leading to higher energy consumption and associated costs. Optimizing system design to match irrigation needs can significantly enhance energy efficiency and reduce overall pumping expenses.

Impact on Pumping Costs

Low pressure irrigation systems generally incur lower pumping costs due to reduced energy consumption required to move water through pipes and emitters. High pressure systems demand more energy, significantly increasing operational expenses, especially in large-scale agricultural operations. Selecting low pressure technology optimizes energy efficiency, thereby reducing overall irrigation water management costs.

System Design Considerations

Low pressure irrigation systems generally require larger pipe diameters and more extensive trenching, increasing upfront installation costs but reducing energy consumption during operation due to lower friction losses. High pressure systems permit smaller piping and more precise water delivery, which enhances irrigation uniformity but often incur higher pumping energy costs because of increased pressure demands. Effective system design must balance initial infrastructure investment with long-term pumping efficiency to optimize overall operational costs and water management outcomes.

Crop and Soil Compatibility

Low-pressure irrigation systems reduce pumping costs by requiring less energy, making them ideal for sandy soils and crops sensitive to water stress, such as lettuce and carrots. High-pressure systems, while more energy-intensive, provide precise water application suitable for heavy clay soils and dense crops like orchards or vineyards. Selecting the appropriate pressure system optimizes water use efficiency and lowers operational expenses based on specific crop water needs and soil infiltration rates.

Maintenance and Longevity Factors

Low pressure irrigation systems generally incur lower pumping costs due to reduced energy requirements but demand more frequent maintenance to prevent clogging and leaks, impacting overall longevity. High pressure systems, while costlier to operate, benefit from durable components and advanced filtration that extend lifespan and reduce downtime. Selecting between low and high pressure setups depends on balancing initial pumping expenses against long-term maintenance efficiency and system durability.

Environmental and Operational Efficiency

Low pressure irrigation systems generally consume less energy, resulting in reduced pumping costs and a smaller carbon footprint compared to high pressure systems. High pressure systems, while offering finer water distribution and better control, often lead to increased energy usage and greater operational expenses. Choosing low pressure systems enhances environmental sustainability by minimizing power consumption and lowering greenhouse gas emissions associated with irrigation pumping.

Choosing the Right System for Your Farm

Low pressure irrigation systems typically reduce pumping costs by requiring less energy to operate, making them ideal for farms aiming to minimize expenses and improve sustainability. High pressure systems, while more costly to run, provide better water distribution and are suited for larger or uneven terrain farms needing precise application. Selecting the right system involves evaluating farm size, topography, crop type, and energy costs to balance operational efficiency with effective water management.

Related Important Terms

Variable Frequency Drive (VFD) Optimization

Variable Frequency Drive (VFD) optimization significantly reduces pumping costs in both low and high pressure irrigation systems by modulating motor speed to match water demand, thereby minimizing energy consumption. High pressure systems benefit more from VFDs due to their typically higher energy usage, but low pressure systems achieve improved efficiency and range control, making VFDs essential for sustainable water management.

Drip Irrigation Pressure Compensation

Low pressure drip irrigation systems with pressure compensation valves reduce pumping costs by maintaining consistent water flow despite pressure variations, optimizing energy use and minimizing waste. High pressure systems increase operational expenses due to greater energy demands and potential damage to drip emitters, impacting overall irrigation efficiency.

Micro-Irrigation Pump Sizing

Low pressure systems in micro-irrigation require smaller pump sizes, reducing energy consumption and operating costs compared to high pressure systems that demand larger, more powerful pumps to maintain adequate flow and pressure. Selecting the appropriate pump size based on system pressure and flow rate optimizes energy efficiency and lowers overall pumping expenses in irrigation water management.

Subsurface Drip Low-Pressure Networks

Subsurface drip low-pressure irrigation systems significantly reduce pumping costs by operating at pressures typically between 10 to 30 psi, compared to high-pressure sprinkler systems requiring 40 to 70 psi, leading to lower energy consumption. This efficiency is enhanced by the direct water application to root zones, minimizing water loss through evaporation and runoff, thus optimizing overall irrigation water management.

Energy Use Intensity (EUI) for Pumps

Low pressure irrigation systems typically exhibit lower Energy Use Intensity (EUI) for pumps compared to high pressure systems due to reduced frictional losses and lower operating pressures. High pressure systems demand greater energy input, increasing operational pumping costs and overall energy consumption in water management.

High Head vs. Low Head System Efficiency

High head pumping systems generally exhibit lower efficiency due to increased energy consumption needed to overcome significant elevation differences, leading to higher operational costs. Low head systems typically achieve better energy efficiency by operating at reduced pressure levels, resulting in lower pumping costs and improved water management sustainability.

Cavitation Risk in Low-Pressure Systems

Low-pressure irrigation systems often incur lower upfront pumping costs but face a higher risk of cavitation, which can damage pumps and increase long-term maintenance expenses. High-pressure systems minimize cavitation risk by maintaining adequate water pressure, resulting in more reliable operation and reduced equipment wear over time.

On-Demand Zonal Pressurization

On-demand zonal pressurization in irrigation systems optimizes pumping costs by delivering water at precise pressures tailored to specific zones, minimizing energy waste commonly associated with high-pressure systems. Low-pressure systems reduce operational expenses through decreased pump energy consumption and lower maintenance needs, enhancing overall efficiency compared to traditional high-pressure setups.

Low Energy Surface Irrigation (LESI)

Low Energy Surface Irrigation (LESI) significantly reduces pumping costs compared to high pressure systems by operating at lower pressures, which decreases energy consumption while maintaining efficient water distribution. LESI utilizes gravity-driven flow and optimized field designs, making it an economically sustainable solution for large-scale agricultural irrigation.

Pressure Regulating Valve (PRV) Integration

Low pressure irrigation systems integrated with Pressure Regulating Valves (PRVs) reduce pumping costs by maintaining optimal operating pressure, minimizing energy consumption and wear on pumps. High pressure systems, without PRVs, often experience excessive energy use and increased maintenance expenses due to pressure fluctuations and system inefficiencies.

Low Pressure vs High Pressure Systems for Pumping Costs Infographic

agridif.com

agridif.com