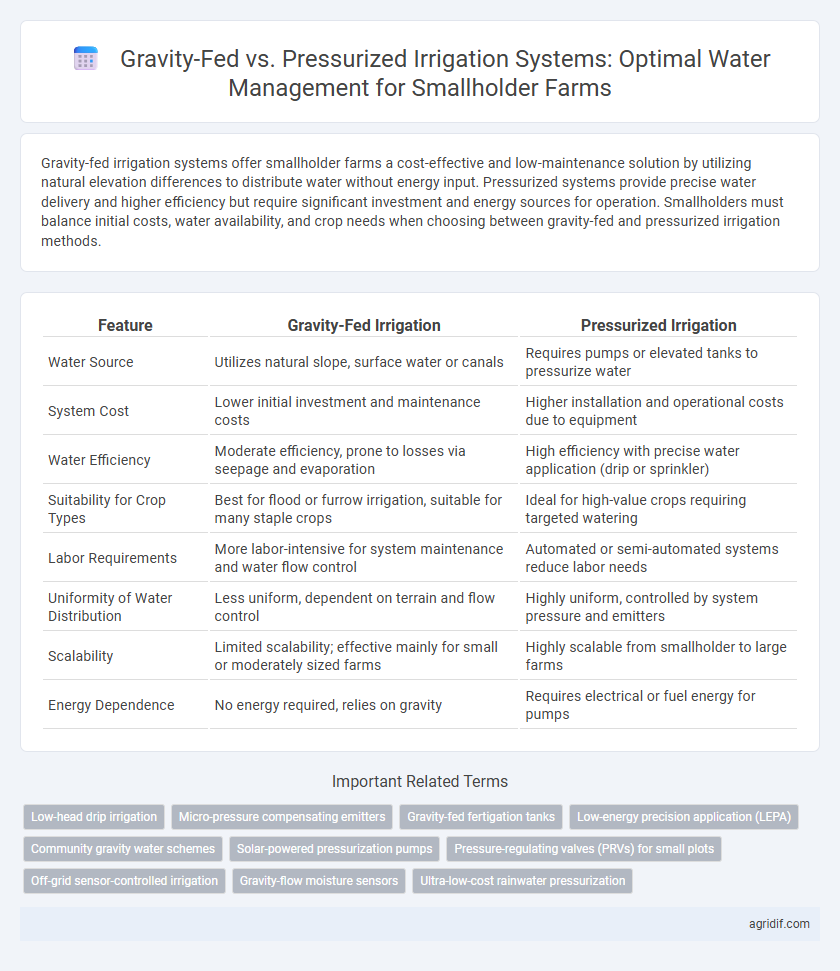

Gravity-fed irrigation systems offer smallholder farms a cost-effective and low-maintenance solution by utilizing natural elevation differences to distribute water without energy input. Pressurized systems provide precise water delivery and higher efficiency but require significant investment and energy sources for operation. Smallholders must balance initial costs, water availability, and crop needs when choosing between gravity-fed and pressurized irrigation methods.

Table of Comparison

| Feature | Gravity-Fed Irrigation | Pressurized Irrigation |

|---|---|---|

| Water Source | Utilizes natural slope, surface water or canals | Requires pumps or elevated tanks to pressurize water |

| System Cost | Lower initial investment and maintenance costs | Higher installation and operational costs due to equipment |

| Water Efficiency | Moderate efficiency, prone to losses via seepage and evaporation | High efficiency with precise water application (drip or sprinkler) |

| Suitability for Crop Types | Best for flood or furrow irrigation, suitable for many staple crops | Ideal for high-value crops requiring targeted watering |

| Labor Requirements | More labor-intensive for system maintenance and water flow control | Automated or semi-automated systems reduce labor needs |

| Uniformity of Water Distribution | Less uniform, dependent on terrain and flow control | Highly uniform, controlled by system pressure and emitters |

| Scalability | Limited scalability; effective mainly for small or moderately sized farms | Highly scalable from smallholder to large farms |

| Energy Dependence | No energy required, relies on gravity | Requires electrical or fuel energy for pumps |

Introduction to Irrigation Methods for Smallholder Farms

Gravity-fed irrigation systems leverage natural topography to distribute water without energy input, making them cost-effective and sustainable for smallholder farms. Pressurized systems, including drip and sprinkler irrigation, offer precise water application and higher efficiency but require investment in pumps and infrastructure. Selecting the appropriate method depends on farm size, water availability, and crop type, balancing initial costs with long-term water use efficiency.

Overview of Gravity-fed Irrigation Systems

Gravity-fed irrigation systems utilize natural land slopes to deliver water from a source to crops, reducing energy costs and maintenance requirements. These systems are particularly suitable for smallholder farms due to their low installation expenses and simple operation, enabling efficient water distribution with minimal infrastructure. Key components include canals, channels, and furrows that guide water flow, making gravity-fed irrigation a sustainable choice in areas with reliable water sources and suitable topography.

Key Features of Pressurized Irrigation Systems

Pressurized irrigation systems for smallholder farms feature precise water delivery through pumps and pipes, enabling efficient water use and uniform distribution. These systems support various irrigation methods such as drip, sprinkler, and micro-sprinkler, which optimize crop water uptake and reduce runoff. Enhanced control over water pressure and timing improves crop yield and resource management compared to gravity-fed systems.

Water Use Efficiency: Gravity-fed vs Pressurized Systems

Gravity-fed irrigation systems rely on natural terrain slope, offering lower water use efficiency due to uneven distribution and potential runoff. Pressurized systems, such as drip or sprinkler irrigation, enhance water use efficiency by delivering precise water amounts directly to plant roots, reducing wastage and evaporation. Studies indicate pressurized systems can improve water use efficiency by up to 40% compared to traditional gravity-fed methods on smallholder farms.

Cost Considerations: Installation and Maintenance

Gravity-fed irrigation systems for smallholder farms typically have lower installation costs due to their reliance on natural water flow, eliminating the need for pumps or extensive wiring. Maintenance expenses remain minimal as there are fewer mechanical parts, reducing repair and energy costs compared to pressurized systems. Pressurized irrigation systems, while offering precise water delivery, require significant initial investment in pumps and pipes, alongside ongoing energy and maintenance expenditures that can strain limited farm budgets.

Suitability for Different Topographies and Crops

Gravity-fed irrigation systems excel in gently sloping terrains where natural water flow can be harnessed efficiently, making them ideal for crops like rice and sugarcane that require consistent water levels. Pressurized systems provide precise water control on varied topographies, including uneven or hilly areas, supporting high-value crops such as vegetables and fruits with tailored irrigation schedules. Smallholder farms benefit from choosing systems based on topography and crop type to optimize water use efficiency and maximize yield.

Energy Requirements and Sustainability

Gravity-fed irrigation systems require minimal to no external energy, relying solely on natural water flow from elevated sources, which significantly reduces operational costs and carbon emissions, promoting sustainable water management for smallholder farms. In contrast, pressurized systems depend on electric or fuel-powered pumps, increasing energy consumption and environmental impact but offering precise water delivery and efficiency in water use. Balancing energy use with water efficiency, gravity-fed systems are more sustainable in regions with suitable topography, while pressurized systems provide flexibility where energy resources are available and water application precision is critical.

Operation, Labor, and Technical Skills Needed

Gravity-fed irrigation systems require minimal operational input and low technical skills, relying on natural water flow which reduces labor demands on smallholder farms. Pressurized systems demand higher maintenance, regular monitoring, and technical know-how to manage pumps and valves effectively, increasing labor intensity and operational complexity. Selecting between these depends on available labor capacity, technical expertise, and resource investment on the farm.

Challenges and Limitations of Both Systems

Gravity-fed irrigation systems face challenges such as uneven water distribution due to variable terrain and limited control over flow rates, which can lead to water wastage and crop stress. Pressurized systems, while offering precise water delivery, often require high initial investment and energy inputs, posing affordability and maintenance difficulties for smallholder farmers. Both systems struggle with infrastructure durability in remote areas, impacting long-term sustainability and consistent water supply.

Recommendations for Smallholder Farmers

Smallholder farmers benefit from gravity-fed irrigation systems due to their low operational costs and minimal energy requirements, which enhance sustainability and reduce dependency on external inputs. Pressurized systems, while offering higher water-use efficiency and precise application, demand greater investment and technical maintenance, potentially limiting accessibility for small-scale operators. For optimal water management, farmers should evaluate local topography, financial resources, and labor availability to select a system that balances cost-effectiveness with irrigation efficiency.

Related Important Terms

Low-head drip irrigation

Low-head drip irrigation systems in gravity-fed setups offer smallholder farms efficient water use by utilizing natural terrain elevation to maintain consistent water pressure without external energy sources. These systems reduce operational costs and enable precise water delivery directly to plant roots, improving crop yields while minimizing water wastage compared to pressurized irrigation systems.

Micro-pressure compensating emitters

Micro-pressure compensating emitters in gravity-fed systems provide uniform water distribution by regulating flow despite pressure variations, enhancing water efficiency on smallholder farms. These emitters reduce runoff and deep percolation compared to pressurized systems, minimizing energy costs while maintaining precise irrigation control essential for varied crop needs.

Gravity-fed fertigation tanks

Gravity-fed fertigation tanks provide an efficient, low-cost irrigation solution for smallholder farms by delivering nutrients and water through natural gravitational flow without the need for energy-intensive pumps. This system enhances water use efficiency and nutrient distribution, reducing operational costs while supporting sustainable crop growth in resource-limited settings.

Low-energy precision application (LEPA)

Gravity-fed systems for smallholder farms utilize natural slope and water flow, reducing energy costs while achieving precise water distribution through Low-Energy Precision Application (LEPA) techniques; however, pressurized systems offer greater control and uniformity in irrigation but require higher energy inputs. LEPA technology maximizes water efficiency and crop yield by delivering water directly to the soil surface, minimizing evaporation and runoff in both system types, though it is especially beneficial in energy-constrained gravity-fed setups.

Community gravity water schemes

Community gravity water schemes for smallholder farms utilize natural topography to deliver water efficiently, reducing energy costs and maintenance compared to pressurized systems. These gravity-fed irrigation setups enhance water access equity while minimizing infrastructure expenses, making them ideal for rural communities with limited resources.

Solar-powered pressurization pumps

Solar-powered pressurization pumps in smallholder farms enhance irrigation efficiency by providing consistent water pressure, enabling precise water delivery compared to gravity-fed systems that depend on terrain and gravity flow, often resulting in uneven distribution. This technology leverages renewable energy to reduce operational costs and water waste, promoting sustainable water management practices critical for improving crop yields in regions with unreliable electricity access.

Pressure-regulating valves (PRVs) for small plots

Pressure-regulating valves (PRVs) enhance the efficiency of irrigation in smallholder farms by maintaining consistent water pressure in both gravity-fed and pressurized systems, preventing pipe damage and ensuring uniform water distribution across small plots. These valves optimize water usage, reduce wastage, and improve crop yields by delivering precise water volumes tailored to the specific needs of varied terrain in small-scale irrigation setups.

Off-grid sensor-controlled irrigation

Gravity-fed systems for smallholder farms offer low-cost, energy-free irrigation but often lack precise water delivery, while pressurized systems enable more controlled and uniform water distribution. Off-grid sensor-controlled irrigation integrated with pressurized systems enhances water efficiency by automatically adjusting flow based on real-time soil moisture data, optimizing crop yield and conserving water resources.

Gravity-flow moisture sensors

Gravity-flow moisture sensors enhance irrigation efficiency in gravity-fed systems by providing real-time soil moisture data without relying on electrical power, making them ideal for smallholder farms with limited resources. These sensors enable precise water management by triggering irrigation only when necessary, reducing water waste and improving crop yield compared to pressurized systems that depend on constant energy inputs.

Ultra-low-cost rainwater pressurization

Ultra-low-cost rainwater pressurization enhances efficiency in smallholder farm irrigation by providing consistent water flow without electricity, outperforming traditional gravity-fed systems that rely on elevation differences. This pressurized approach optimizes water use, reduces labor, and boosts crop yields through more precise irrigation control.

Gravity-fed systems vs Pressurized systems for smallholder farms Infographic

agridif.com

agridif.com