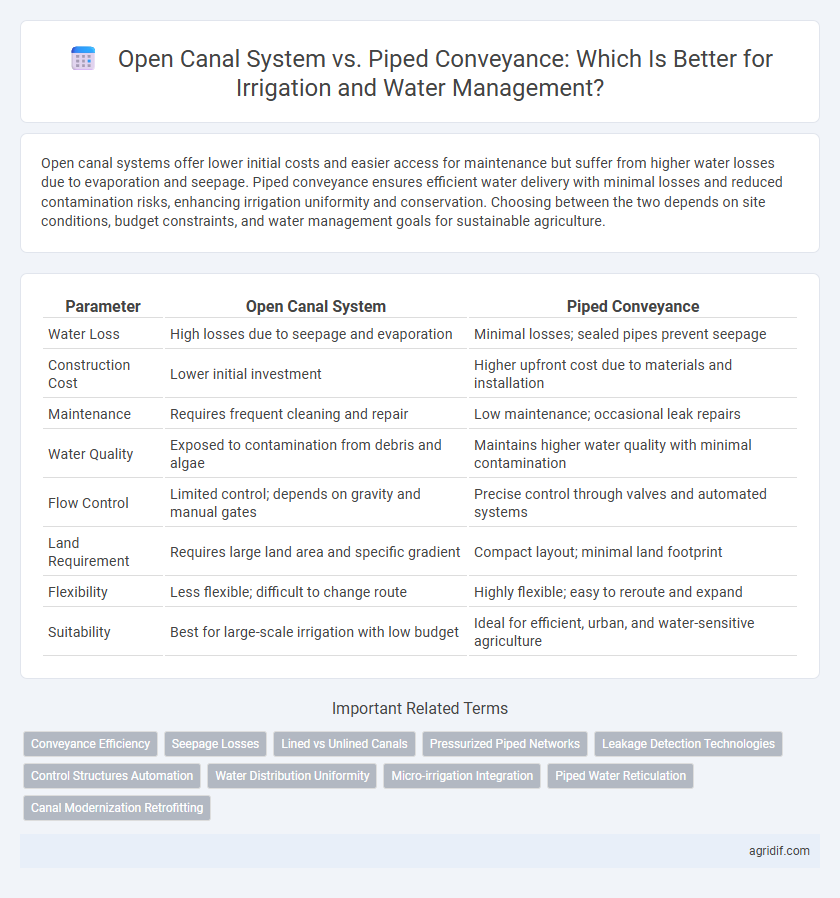

Open canal systems offer lower initial costs and easier access for maintenance but suffer from higher water losses due to evaporation and seepage. Piped conveyance ensures efficient water delivery with minimal losses and reduced contamination risks, enhancing irrigation uniformity and conservation. Choosing between the two depends on site conditions, budget constraints, and water management goals for sustainable agriculture.

Table of Comparison

| Parameter | Open Canal System | Piped Conveyance |

|---|---|---|

| Water Loss | High losses due to seepage and evaporation | Minimal losses; sealed pipes prevent seepage |

| Construction Cost | Lower initial investment | Higher upfront cost due to materials and installation |

| Maintenance | Requires frequent cleaning and repair | Low maintenance; occasional leak repairs |

| Water Quality | Exposed to contamination from debris and algae | Maintains higher water quality with minimal contamination |

| Flow Control | Limited control; depends on gravity and manual gates | Precise control through valves and automated systems |

| Land Requirement | Requires large land area and specific gradient | Compact layout; minimal land footprint |

| Flexibility | Less flexible; difficult to change route | Highly flexible; easy to reroute and expand |

| Suitability | Best for large-scale irrigation with low budget | Ideal for efficient, urban, and water-sensitive agriculture |

Introduction to Agricultural Water Delivery Systems

Open canal systems are traditional water conveyance methods characterized by exposed channels that rely on gravity flow for irrigation delivery, making them cost-effective but prone to water loss through seepage and evaporation. Piped conveyance systems use enclosed pipelines to transport water, significantly reducing losses and improving delivery efficiency, though they require higher initial investment and maintenance. Selecting a suitable agricultural water delivery system depends on factors like topography, water availability, and infrastructure budget to optimize water use efficiency and crop yield.

Overview of Open Canal Irrigation

Open canal irrigation systems transport water through unlined or lined channels, relying on gravity flow to deliver water to agricultural fields efficiently. These systems are cost-effective for large-scale irrigation but face challenges like water loss due to seepage, evaporation, and surface runoff. Proper maintenance and design improvements, such as lining canals, help optimize water use and enhance delivery efficiency in open canal irrigation.

Basics of Piped Conveyance Systems

Piped conveyance systems use closed pipelines to transport water, minimizing losses from seepage and evaporation compared to open canal systems. These pipelines can be constructed from materials such as PVC, HDPE, or steel, designed for efficient pressure flow and reduced contamination risks. Proper maintenance of piped conveyance ensures reliable water delivery, enhanced control, and higher irrigation efficiency in water management.

Water Losses: Evaporation, Seepage, and Leakage

Open canal systems in irrigation experience significant water losses due to evaporation, seepage, and leakage, often resulting in up to 30-40% reduction in delivered water volume. Piped conveyance systems minimize these losses by providing a closed conduit, reducing evaporation to nearly zero and seepage to negligible levels, thus improving water use efficiency by 20-30% compared to open canals. Selecting piped systems enhances water conservation, particularly in arid regions where evaporation rates exceed 5 mm/day.

Installation and Maintenance Costs Comparison

Open canal systems typically incur lower initial installation costs due to the use of natural land contours and simpler construction techniques, while piped conveyance requires significant investment in materials like PVC or steel pipes and skilled labor for proper installation. Maintenance costs for open canals are generally higher because they demand regular cleaning, desilting, and repairs to prevent leaks and breaches caused by erosion or vegetation growth. Piped conveyance systems offer reduced maintenance frequency and minimize water losses but involve higher expenses for occasional pipe replacements and repairs in case of leaks or blockages.

Water Quality and Contamination Concerns

Open canal systems are more prone to contamination due to exposure to external pollutants such as sediments, pesticides, and animal waste, leading to decreased water quality in irrigation schemes. Piped conveyance minimizes water quality degradation by providing a closed environment that reduces contamination risks and limits evaporation and seepage losses. Selecting piped systems enhances control over water purity, critical for maintaining soil health and crop productivity in agricultural water management.

Flexibility and Adaptability to Terrain

Open canal systems offer superior flexibility and adaptability to varied terrain due to their ability to follow natural land contours and easily modify channel paths for changing agricultural needs. Piped conveyance systems, while efficient in minimizing water loss, require precise initial design and significant excavation or infrastructure adjustments, limiting adaptability to uneven or shifting terrains. Open canals also facilitate easier inspection, maintenance, and localized water distribution adjustments in complex landscapes compared to rigid piped networks.

Energy Requirements for Water Conveyance

Open canal systems typically require less energy for water conveyance due to gravity flow, minimizing the need for pumping stations and mechanical energy input. Piped conveyance demands higher energy consumption as water is pressurized and transported through sealed networks, often relying on pumps to overcome elevation changes and friction losses. Energy efficiency in irrigation is significantly influenced by the conveyance method, with open canals favored in flat terrains and piped systems preferred where precise control and water conservation are critical.

Impact on Crop Yield and Farm Productivity

Open canal systems often experience significant water loss due to seepage and evaporation, reducing water availability for crops and potentially lowering yield and farm productivity. Piped conveyance minimizes water losses by delivering water directly to fields, enhancing water use efficiency and supporting higher crop yields. Studies show farms using piped systems achieve up to 20% greater productivity compared to those relying on open canals.

Environmental and Sustainability Considerations

Open canal systems often lead to higher water loss through evaporation and seepage, negatively impacting water conservation efforts and local ecosystems. Piped conveyance minimizes water loss and contamination risks, promoting sustainable water management by ensuring efficient delivery and protecting surrounding soil and habitats from erosion and pollution. Implementing piped systems supports environmental sustainability by reducing water waste and maintaining groundwater levels more effectively than open canals.

Related Important Terms

Conveyance Efficiency

Open canal systems typically exhibit conveyance efficiencies ranging from 40% to 60% due to water losses from seepage, evaporation, and surface runoff, while piped conveyance systems achieve efficiencies of 85% to 95% by minimizing these losses through enclosed transport. The higher conveyance efficiency in piped systems directly contributes to improved water management, reducing water wastage and ensuring more reliable irrigation supply for agricultural activities.

Seepage Losses

Open canal systems experience significantly higher seepage losses, often ranging between 20% to 40% of conveyed water, due to direct soil-water contact and porous canal beds. In contrast, piped conveyance minimizes seepage losses to near zero by providing a sealed conduit, enhancing water delivery efficiency and reducing water wastage in irrigation and water management.

Lined vs Unlined Canals

Lined canals in open canal irrigation systems minimize seepage losses and reduce waterlogging compared to unlined canals, enhancing water conveyance efficiency. While unlined canals are cheaper and easier to construct, they suffer from higher infiltration rates, leading to substantial water loss and decreased delivery reliability.

Pressurized Piped Networks

Pressurized piped networks offer precise water delivery with minimal losses, enhancing irrigation efficiency compared to open canal systems prone to evaporation and seepage. These systems enable automated flow control and reduce contamination risks, optimizing water management in agricultural settings.

Leakage Detection Technologies

Open canal systems often suffer from significant water loss due to seepage and evaporation, making leakage detection technologies such as aerial thermal imaging and ground-penetrating radar critical for minimizing inefficiencies. In contrast, piped conveyance systems benefit from advanced sensor networks and pressure monitoring, enabling real-time identification and rapid repair of leaks to ensure optimal water delivery in irrigation management.

Control Structures Automation

Control structures automation in piped conveyance systems enhances precise water delivery and reduces losses by enabling real-time flow regulation, unlike open canal systems which rely on manual adjustments and are prone to evaporation and seepage. Automated valves and sensors in pipelines optimize irrigation scheduling, improve water use efficiency, and minimize operational labor compared to traditional open canals.

Water Distribution Uniformity

Open canal systems often suffer from uneven water distribution due to seepage, evaporation, and flow variability, leading to lower water distribution uniformity compared to piped conveyance systems. Piped conveyance minimizes losses through leakage and evaporation, ensuring more consistent water delivery and higher distribution uniformity in irrigation networks.

Micro-irrigation Integration

Open canal systems offer cost-effective water delivery but suffer from high evaporation and seepage losses, limiting their efficiency for micro-irrigation integration; piped conveyance ensures precise water application with minimal losses, enhancing water use efficiency and uniform distribution critical for drip and sprinkler micro-irrigation systems. Implementing piped networks supports better pressure control and integration of automation technologies, optimizing irrigation schedules and reducing labor costs compared to traditional open canal methods.

Piped Water Reticulation

Piped water reticulation systems offer precise water delivery, minimizing losses from seepage and evaporation typical in open canal irrigation. These systems enhance water use efficiency and reduce contamination risks, promoting sustainable irrigation and improved crop yield.

Canal Modernization Retrofitting

Canal modernization retrofitting enhances water conveyance efficiency by reducing seepage losses and improving flow control in open canal systems, often achieving water savings of 20-30%. Piped conveyance, while minimizing evaporation and contamination, involves higher initial costs and maintenance complexity compared to retrofitted open canals designed to optimize existing infrastructure.

Open canal system vs piped conveyance for water delivery Infographic

agridif.com

agridif.com