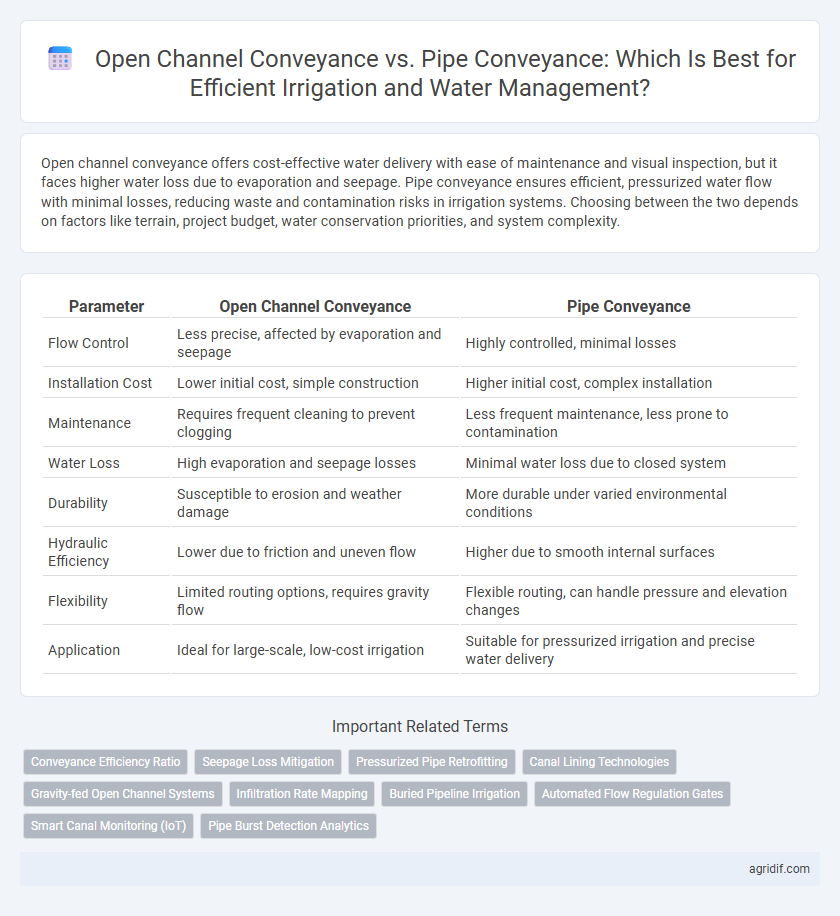

Open channel conveyance offers cost-effective water delivery with ease of maintenance and visual inspection, but it faces higher water loss due to evaporation and seepage. Pipe conveyance ensures efficient, pressurized water flow with minimal losses, reducing waste and contamination risks in irrigation systems. Choosing between the two depends on factors like terrain, project budget, water conservation priorities, and system complexity.

Table of Comparison

| Parameter | Open Channel Conveyance | Pipe Conveyance |

|---|---|---|

| Flow Control | Less precise, affected by evaporation and seepage | Highly controlled, minimal losses |

| Installation Cost | Lower initial cost, simple construction | Higher initial cost, complex installation |

| Maintenance | Requires frequent cleaning to prevent clogging | Less frequent maintenance, less prone to contamination |

| Water Loss | High evaporation and seepage losses | Minimal water loss due to closed system |

| Durability | Susceptible to erosion and weather damage | More durable under varied environmental conditions |

| Hydraulic Efficiency | Lower due to friction and uneven flow | Higher due to smooth internal surfaces |

| Flexibility | Limited routing options, requires gravity flow | Flexible routing, can handle pressure and elevation changes |

| Application | Ideal for large-scale, low-cost irrigation | Suitable for pressurized irrigation and precise water delivery |

Overview of Water Delivery Systems in Agriculture

Open channel conveyance systems, typically involving earthen, lined, or concrete canals, are widely used for agricultural water delivery due to their cost-effectiveness and ease of construction over large areas. Pipe conveyance systems offer improved water use efficiency by minimizing seepage and evaporation losses, essential for precision irrigation and areas with limited water availability. Selection between these systems depends on factors such as topography, soil type, water availability, and farm size, influencing overall irrigation efficiency and crop yield.

Open Channel Conveyance: Definition and Key Features

Open channel conveyance refers to the transportation of water through natural or artificial open channels such as canals, ditches, and rivers. Key features include gravity-driven flow, surface water exposure, lower construction costs, and ease of maintenance and inspection. This method is highly effective for irrigation projects requiring large volumes of water over gentle slopes with moderate flow velocity.

Pipe Conveyance: Definition and Key Features

Pipe conveyance in irrigation and water management refers to the transportation of water through enclosed pipelines made from materials like PVC, steel, or HDPE, designed to minimize water loss and contamination. Key features include high hydraulic efficiency due to reduced friction and seepage, greater control over flow rates and pressure, and the ability to transport water over varied terrains with minimal evaporation. This method supports modern irrigation systems by enabling precise water delivery, improving overall system durability and maintenance ease compared to traditional open channel conveyance.

Comparative Water Losses: Seepage and Evaporation

Open channel conveyance systems experience higher water losses due to seepage, with losses ranging from 10% to 40% depending on soil permeability, whereas pipe conveyance typically limits seepage losses to less than 1% by utilizing impermeable materials. Evaporation losses are significant in open channels, especially in arid regions, often accounting for 20% or more of delivered water, while closed pipe systems minimize evaporation due to reduced exposure to the atmosphere. Overall, pipe conveyance offers superior water conservation by drastically reducing both seepage and evaporation losses compared to open channel methods.

Energy Requirements and Operational Efficiency

Open channel conveyance systems typically require less energy for water delivery due to gravity flow but face higher water losses through evaporation and seepage, impacting overall operational efficiency. Pipe conveyance systems demand energy for pumping but minimize water loss and enable more precise control, enhancing delivery efficiency especially in areas with variable terrain. Energy requirements favor open channels in flat regions, while operational efficiency and water conservation make pipe systems preferable in water-scarce or hilly environments.

Installation and Maintenance Considerations

Open channel conveyance systems require extensive land grading and ongoing debris removal to maintain flow efficiency, while pipe conveyance involves higher initial installation costs due to trenching and pipe laying but offers reduced surface area exposure and less frequent maintenance. In open channels, erosion control and sediment buildup demand regular inspection and repairs, whereas pipe systems face challenges such as joint leaks and blockage, necessitating periodic flushing and mechanical cleaning. Installation of pipe conveyance provides better protection against contamination and evaporation losses compared to open channels, making maintenance more predictable and potentially less labor-intensive over time.

Water Quality Impacts in Conveyance Methods

Open channel conveyance often results in water quality degradation due to exposure to contaminants, sedimentation, and evaporation, leading to increased turbidity and microbial pollution. Pipe conveyance systems minimize contamination risks by providing a closed environment, reducing exposure to pollutants and preventing water loss through seepage and evaporation. Preferring pipe conveyance enhances water quality retention, crucial for irrigation efficiency and protecting downstream ecosystems.

Cost Analysis: Initial Investment and Long-Term Expenses

Open channel conveyance systems typically require lower initial investment costs compared to pipe conveyance due to simpler construction and readily available materials, but they incur higher long-term expenses linked to frequent maintenance, sedimentation removal, and water loss through seepage and evaporation. Pipe conveyance demands a higher upfront capital outlay for materials, installation, and specialized labor, yet offers reduced operational costs by minimizing water loss and maintenance frequency, enhancing overall cost efficiency in the long term. Cost analysis should prioritize the trade-offs between upfront capital expenditure and lifecycle expenses, considering site-specific factors like terrain, water volume, and maintenance infrastructure.

Suitability for Different Agricultural Landscapes

Open channel conveyance suits large, flat agricultural landscapes where gravity flow efficiently transports water with minimal energy input. Pipe conveyance excels in undulating or fragmented terrains, ensuring pressurized delivery and reducing water loss through seepage and evaporation. Selecting the appropriate system depends on factors such as soil type, field layout, crop water requirements, and overall water conservation goals.

Sustainability and Future Trends in Irrigation Conveyance

Open channel conveyance systems, traditionally favored for irrigation due to low cost and ease of construction, face sustainability challenges such as water loss from seepage and evaporation. Pipe conveyance offers enhanced water delivery efficiency, reduced leakage, and better protection against contamination, aligning with future trends emphasizing water conservation and precision irrigation. Advances in smart irrigation technologies and remotely monitored pipeline networks are driving a shift towards pipeline systems to optimize water use and support sustainable agricultural practices.

Related Important Terms

Conveyance Efficiency Ratio

Open channel conveyance typically exhibits conveyance efficiency ratios ranging from 50% to 80% due to water losses from seepage and evaporation, whereas pipe conveyance systems achieve efficiency ratios above 90% by minimizing leakage and environmental exposure. Selecting pipe conveyance enhances water delivery reliability and reduces operational water loss in irrigation and water management projects.

Seepage Loss Mitigation

Open channel conveyance often experiences significant seepage losses due to soil permeability, making it less efficient for water delivery. Pipe conveyance systems, constructed with impermeable materials, effectively mitigate seepage loss by preventing water infiltration into surrounding soil, thereby improving water conservation and delivery efficiency.

Pressurized Pipe Retrofitting

Pressurized pipe retrofitting in irrigation systems enhances water delivery efficiency by minimizing leakage and evaporation losses compared to traditional open channel conveyance. This upgrade also allows for precise flow control and reduced land use, promoting sustainable water management and improved crop yield.

Canal Lining Technologies

Canal lining technologies in open channel conveyance significantly reduce seepage losses and increase water delivery efficiency compared to unlined canals, while pipe conveyance systems offer superior leak control and pressure management but at higher installation costs. Selection between lined canals and pipe conveyance depends on factors such as soil permeability, water availability, maintenance capacity, and economic considerations.

Gravity-fed Open Channel Systems

Gravity-fed open channel systems for irrigation leverage natural slope and gravitational force to transport water efficiently over long distances without the need for pumps, reducing energy costs and maintenance. Unlike pipe conveyance, open channels allow for easy inspection, adaptation to varying flow rates, and integration with field drainage, but they require careful design to minimize seepage, evaporation losses, and contamination risks.

Infiltration Rate Mapping

Open channel conveyance systems exhibit higher infiltration rates due to direct soil-water interaction, necessitating detailed infiltration rate mapping for efficient water management. Pipe conveyance reduces infiltration losses by delivering water through closed conduits, making infiltration rate mapping less critical but important for leak detection and maintenance planning.

Buried Pipeline Irrigation

Buried pipeline irrigation minimizes water loss through seepage and evaporation compared to open channel conveyance, enhancing efficiency in water delivery by maintaining controlled flow and reducing contamination risks. The enclosed system also supports higher pressure and flow rates, enabling precise water distribution with lower maintenance requirements and reduced land use.

Automated Flow Regulation Gates

Automated flow regulation gates in open channel conveyance systems enable real-time adjustments to water distribution, enhancing efficiency and minimizing water loss compared to pipe conveyance, which faces challenges in automated flow control due to pressurization and pipe friction. Integration of smart sensors and actuators in open channels facilitates precise irrigation scheduling and reduced operational costs for large-scale agricultural water management.

Smart Canal Monitoring (IoT)

Open channel conveyance allows real-time water flow monitoring through IoT-enabled smart sensors that detect parameters such as flow rate, water level, and quality, enhancing efficient irrigation management. In contrast, pipe conveyance systems integrate IoT devices for precise leak detection and pressure monitoring, enabling proactive maintenance and reducing water loss in water delivery networks.

Pipe Burst Detection Analytics

Pipe burst detection analytics in irrigation systems leverage real-time sensor data and machine learning algorithms to identify pressure anomalies and flow rate deviations, enabling rapid response to minimize water loss and crop damage. Compared to open channel conveyance, pipe systems benefit significantly from burst detection technology due to enclosed infrastructure, which prevents visual leak identification and requires advanced monitoring for efficient water management.

Open Channel Conveyance vs Pipe Conveyance for Water Delivery Infographic

agridif.com

agridif.com