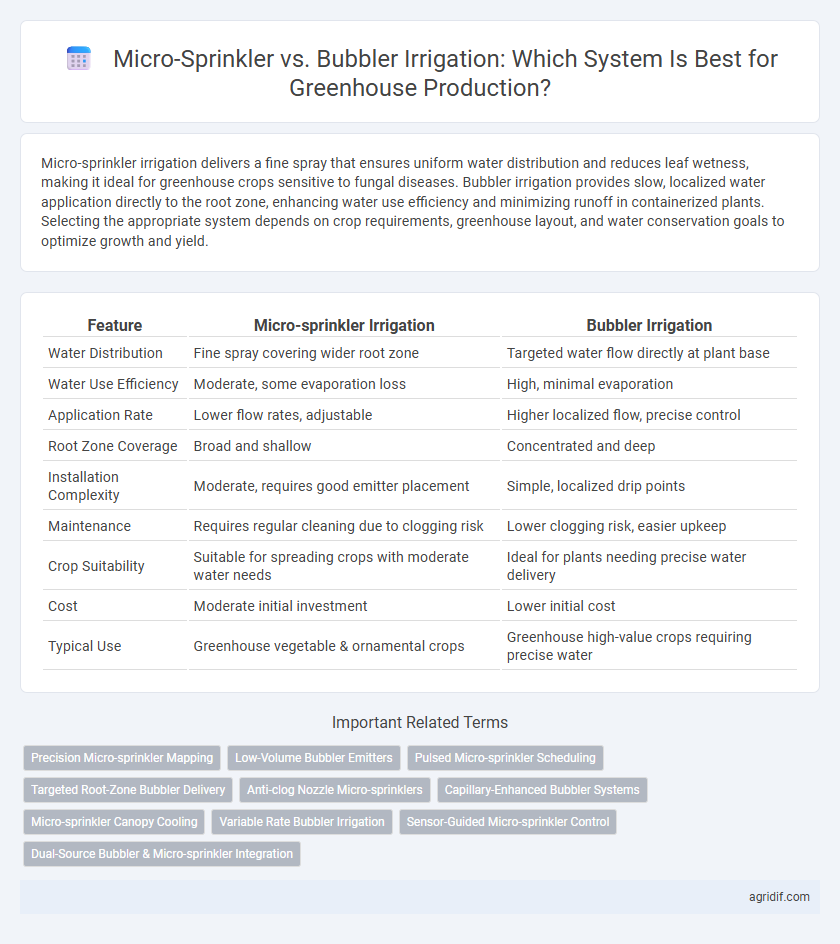

Micro-sprinkler irrigation delivers a fine spray that ensures uniform water distribution and reduces leaf wetness, making it ideal for greenhouse crops sensitive to fungal diseases. Bubbler irrigation provides slow, localized water application directly to the root zone, enhancing water use efficiency and minimizing runoff in containerized plants. Selecting the appropriate system depends on crop requirements, greenhouse layout, and water conservation goals to optimize growth and yield.

Table of Comparison

| Feature | Micro-sprinkler Irrigation | Bubbler Irrigation |

|---|---|---|

| Water Distribution | Fine spray covering wider root zone | Targeted water flow directly at plant base |

| Water Use Efficiency | Moderate, some evaporation loss | High, minimal evaporation |

| Application Rate | Lower flow rates, adjustable | Higher localized flow, precise control |

| Root Zone Coverage | Broad and shallow | Concentrated and deep |

| Installation Complexity | Moderate, requires good emitter placement | Simple, localized drip points |

| Maintenance | Requires regular cleaning due to clogging risk | Lower clogging risk, easier upkeep |

| Crop Suitability | Suitable for spreading crops with moderate water needs | Ideal for plants needing precise water delivery |

| Cost | Moderate initial investment | Lower initial cost |

| Typical Use | Greenhouse vegetable & ornamental crops | Greenhouse high-value crops requiring precise water |

Introduction to Micro-sprinkler and Bubbler Irrigation in Greenhouses

Micro-sprinkler irrigation delivers fine droplets uniformly, promoting efficient water distribution and reduced leaf wetness in greenhouse crops, which minimizes disease risk. Bubbler irrigation releases a slow, steady flow of water directly at the plant base, enhancing deep root moisture while conserving water and reducing runoff. Both methods offer targeted irrigation suited to specific crop requirements and soil conditions, improving water use efficiency in controlled greenhouse environments.

System Design and Installation Requirements

Micro-sprinkler irrigation systems require precise emitter spacing and pressure regulation to ensure uniform water distribution and avoid canopy wetting, which reduces disease risk in greenhouse production. Bubbler irrigation systems involve low-pressure, low-flow emitters that deliver water directly to the root zone, necessitating careful placement near plant bases and a simple downline piping network for effective installation. Both systems demand filtration units to prevent clogging, but micro-sprinklers often require more complex pressure regulation and network layout compared to the more straightforward installation of bubblers.

Water Distribution Uniformity

Micro-sprinkler irrigation provides moderate water distribution uniformity with a fine spray pattern suitable for covering larger areas in greenhouse production. Bubbler irrigation delivers higher water distribution uniformity by releasing water directly at the root zone, minimizing evaporation and runoff. Optimizing uniformity enhances water use efficiency and promotes consistent crop growth in controlled environments.

Suitability for Different Greenhouse Crops

Micro-sprinkler irrigation suits greenhouse crops requiring uniform water distribution and moderate humidity, such as leafy greens and herbs, promoting optimal growth without waterlogging. Bubbler irrigation delivers targeted water directly to the root zone, ideal for fruiting vegetables and crops sensitive to foliage wetting, reducing disease risk. Crop type, root depth, and greenhouse microclimate guide the choice between these systems for efficient water management.

Water Use Efficiency

Micro-sprinkler irrigation delivers water uniformly over the soil surface, enhancing water use efficiency by reducing evaporation and runoff in greenhouse environments. Bubbler irrigation targets the root zone more directly, minimizing water waste and improving uptake but may lead to uneven soil moisture distribution in dense planting systems. Comparative studies show micro-sprinklers generally achieve higher water use efficiency in greenhouse production due to their broader coverage and better adaptation to varying crop layouts.

Impact on Soil Moisture Management

Micro-sprinkler irrigation provides fine water droplets that enhance uniform soil moisture distribution, reducing water runoff and promoting efficient root zone hydration in greenhouse production. Bubbler irrigation delivers water directly to the soil surface in concentrated streams, allowing precise control of soil moisture levels but potentially causing uneven wetting patterns. Optimizing soil moisture management in greenhouses depends on crop type and substrate, with micro-sprinklers offering better evaporation control and bubblers enabling targeted irrigation zones.

Disease and Pest Control Considerations

Micro-sprinkler irrigation delivers water as fine droplets, promoting higher humidity levels that can increase the risk of fungal diseases in greenhouse crops, whereas bubbler irrigation applies water directly to the soil surface, reducing leaf wetness and minimizing pathogen spread. Bubbler systems limit the moisture on plant foliage, decreasing pest habitats such as aphids and thrips that thrive in damp conditions, while micro-sprinklers may inadvertently facilitate pest movement due to water dispersion. Choosing bubbler irrigation in greenhouse production enhances disease and pest control by maintaining targeted soil moisture without creating a conducive environment for pathogens and insects.

Energy and Maintenance Costs

Micro-sprinkler irrigation in greenhouse production typically incurs higher energy costs due to increased pressure requirements, while bubblers operate efficiently at lower pressures, leading to reduced energy consumption. Maintenance costs for micro-sprinklers are elevated because of frequent clogging and nozzle replacement, whereas bubblers demand less frequent upkeep due to their simpler design and lower vulnerability to blockages. Selecting bubblers can optimize operational budgets by minimizing both energy use and maintenance interventions in controlled environment agriculture.

Adaptability to Automation and Smart Controls

Micro-sprinkler irrigation systems offer higher adaptability to automation and smart controls due to their uniform water distribution and compatibility with advanced sensors and timers, enabling precise scheduling and variable rate watering in greenhouse production. Bubbler irrigation, while efficient for targeted root zone watering, presents challenges in integration with automated systems because of localized flow variability and potential clogging issues, limiting real-time adjustments. Implementing micro-sprinklers with IoT-enabled controllers enhances water use efficiency and crop yield by optimizing irrigation based on real-time environmental data within greenhouse environments.

Environmental and Sustainability Implications

Micro-sprinkler irrigation delivers water through fine spray patterns, reducing water runoff and improving uniformity, which minimizes resource waste in greenhouse production. Bubbler irrigation applies water at a slower rate directly to the root zone, enhancing water use efficiency and reducing evaporative losses, contributing to sustainable water management. Both methods reduce energy consumption compared to traditional irrigation, but bubblers often offer better nutrient delivery control, critical for sustainable and environmentally responsible greenhouse operations.

Related Important Terms

Precision Micro-sprinkler Mapping

Precision micro-sprinkler mapping enhances greenhouse irrigation by delivering uniform water distribution and precise control over microclimate conditions, improving crop yield and water use efficiency compared to bubbler systems. Micro-sprinklers facilitate adjustable droplet size and spray radius, enabling targeted irrigation that minimizes water waste and reduces disease risk from leaf wetting, critical for high-value greenhouse crops.

Low-Volume Bubbler Emitters

Low-volume bubbler emitters provide precise water delivery directly to the root zone, improving water use efficiency and reducing runoff in greenhouse production compared to micro-sprinklers. These emitters minimize evaporation and promote uniform soil moisture distribution, enhancing plant health while conserving water resources.

Pulsed Micro-sprinkler Scheduling

Pulsed micro-sprinkler scheduling in greenhouse production enhances water use efficiency by delivering precise, intermittent applications tailored to plant water uptake, reducing runoff and evaporation compared to continuous bubbler irrigation. This method optimizes root zone moisture levels, promotes uniform soil wetting, and supports better crop growth in controlled environments.

Targeted Root-Zone Bubbler Delivery

Targeted root-zone bubbler delivery in greenhouse production enhances water efficiency by delivering precise volumes directly to the plant base, minimizing evaporation and runoff compared to micro-sprinklers. This method improves soil moisture uniformity and reduces leaf wetness, which helps prevent disease and promotes healthier crop growth in controlled environments.

Anti-clog Nozzle Micro-sprinklers

Anti-clog nozzle micro-sprinklers provide precise water distribution and reduce maintenance downtime in greenhouse irrigation compared to bubbler systems, which often suffer from uneven flow and higher clogging risks. Their ability to maintain uniform water droplets enhances plant health and water use efficiency, making them ideal for controlled-environment agriculture.

Capillary-Enhanced Bubbler Systems

Capillary-enhanced bubbler systems improve water distribution uniformity by combining low-flow bubblers with capillary mats, resulting in efficient irrigation and enhanced root zone moisture control ideal for greenhouse production. Micro-sprinkler irrigation offers broader coverage but often leads to higher evaporation and less targeted water delivery compared to the precision and reduced water waste achieved by capillary-enhanced bubbler systems.

Micro-sprinkler Canopy Cooling

Micro-sprinkler systems provide effective canopy cooling in greenhouse production by evenly distributing fine water droplets that reduce ambient temperature and increase humidity, optimizing plant growth conditions. Compared to bubbler irrigation, micro-sprinklers enhance microclimate control and minimize water wastage through precise application, making them ideal for efficient water management in controlled environments.

Variable Rate Bubbler Irrigation

Variable Rate Bubbler Irrigation offers precise water delivery by adjusting flow rates based on plant needs, reducing water waste and enhancing crop yield in greenhouse environments. Compared to micro-sprinklers, bubblers provide better root zone targeting and minimize evaporation, making them more efficient for controlled irrigation management.

Sensor-Guided Micro-sprinkler Control

Sensor-guided micro-sprinkler irrigation in greenhouse production enhances water use efficiency by precisely adjusting water distribution based on real-time soil moisture and environmental data, outperforming traditional bubbler systems that provide fixed and less uniform water application. This technology significantly reduces water wastage, promotes uniform crop growth, and supports sustainable water management practices in controlled environments.

Dual-Source Bubbler & Micro-sprinkler Integration

Dual-source bubbler and micro-sprinkler integration in greenhouse irrigation enhances water distribution uniformity and optimizes resource use by delivering precise moisture levels tailored to varying crop needs. This combined system maximizes efficiency, reduces water waste, and improves plant health through targeted root zone and canopy irrigation control.

Micro-sprinkler vs Bubbler irrigation for greenhouse production Infographic

agridif.com

agridif.com