All-in-all-out flock management enhances biosecurity by allowing thorough cleaning and disinfection between batches, reducing disease transmission in poultry farming pets. Continuous stocking maintains a constant population but increases the risk of pathogen buildup and complicates health monitoring. Choosing all-in-all-out supports healthier flocks through controlled environments and minimizes cross-contamination risks.

Table of Comparison

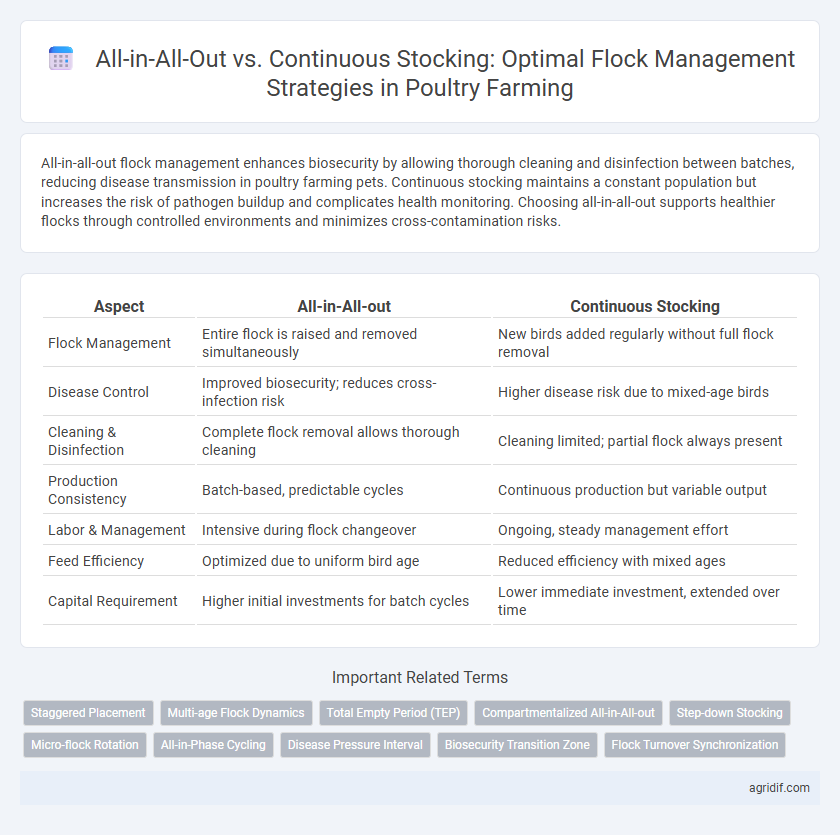

| Aspect | All-in-All-out | Continuous Stocking |

|---|---|---|

| Flock Management | Entire flock is raised and removed simultaneously | New birds added regularly without full flock removal |

| Disease Control | Improved biosecurity; reduces cross-infection risk | Higher disease risk due to mixed-age birds |

| Cleaning & Disinfection | Complete flock removal allows thorough cleaning | Cleaning limited; partial flock always present |

| Production Consistency | Batch-based, predictable cycles | Continuous production but variable output |

| Labor & Management | Intensive during flock changeover | Ongoing, steady management effort |

| Feed Efficiency | Optimized due to uniform bird age | Reduced efficiency with mixed ages |

| Capital Requirement | Higher initial investments for batch cycles | Lower immediate investment, extended over time |

Introduction to Flock Management Systems

All-in-All-out flock management involves raising poultry populations in discrete groups, completely clearing and disinfecting housing between batches to reduce disease transmission and improve biosecurity. Continuous stocking maintains a constant population by adding and removing birds as needed, which can lead to higher risks of pathogen buildup and uneven growth rates. Choosing the appropriate system directly impacts flock health, productivity, and operational efficiency in poultry farming.

What is All-in-All-out in Poultry Farming?

All-in-All-out in poultry farming is a flock management system where all birds of the same age are raised together and removed simultaneously before a new flock is introduced. This method minimizes disease transmission by allowing complete cleaning and disinfection between flocks. Implementing All-in-All-out enhances biosecurity and promotes healthier, more productive poultry operations.

Understanding Continuous Stocking Methods

Continuous stocking in poultry farming involves maintaining multiple age groups of birds in the same facility simultaneously, which allows for constant production but increases the risk of disease transmission between flocks. This method requires rigorous biosecurity measures and frequent monitoring to manage pathogen spread and maintain flock health effectively. Understanding continuous stocking helps optimize space utilization and labor efficiency while balancing challenges related to sanitation and health management.

Biosecurity Implications of Each System

All-in-all-out flock management significantly reduces the risk of disease transmission by allowing complete cleaning and disinfection between batches, effectively breaking the pathogen cycle. Continuous stocking increases biosecurity challenges due to overlapping age groups, promoting persistent contamination and complex infection dynamics within the flock. Implementing strict biosecurity protocols is critical in continuous systems to mitigate the higher risk of disease persistence and spread.

Disease Control: Comparing Both Approaches

All-in-All-out flock management minimizes disease risk by allowing complete cleaning and disinfection between batches, effectively breaking the disease transmission cycle. Continuous stocking increases the potential for pathogen buildup and persistent infections due to overlapping bird populations and continual exposure. Effective disease control in poultry farming favors All-in-All-out systems for reducing outbreaks and improving flock health.

Productivity and Growth Rate Differences

All-in-All-out flock management segregates bird groups by age, minimizing disease transmission and promoting uniform growth rates, which enhances overall productivity compared to Continuous Stocking. Continuous Stocking involves introducing new birds regularly, increasing disease risk and causing uneven growth rates, ultimately reducing feed efficiency and weight gain metrics. Studies indicate All-in-All-out systems can improve feed conversion ratios by up to 15% and reduce mortality rates, leading to higher profit margins in poultry production.

Labor and Operational Efficiency

All-in-all-out flock management enhances labor and operational efficiency by enabling thorough cleaning and disinfection between cycles, minimizing disease risk and downtime. Continuous stocking requires constant labor for ongoing care, complicating scheduling and increasing operational costs due to overlapping flock ages. Optimal labor allocation and workflow predictability are achieved with all-in-all-out systems, improving overall productivity in poultry farming.

Economic Impact on Poultry Operations

All-in-All-out flock management enhances biosecurity and reduces disease transmission, leading to lower mortality rates and fewer veterinary costs, which significantly improves profitability in poultry operations. Continuous stocking offers flexibility and constant production but often results in higher feed conversion ratios and increased disease risks, elevating overall expenses. Economic analyses demonstrate that while continuous stocking may provide steady revenue, the higher health management costs and potential production losses make All-in-All-out more cost-effective for optimizing long-term poultry farm profitability.

Environmental and Welfare Considerations

All-in-All-out flock management reduces disease transmission and environmental contamination by allowing complete cleaning and disinfection between batches, enhancing biosecurity and bird welfare. Continuous stocking can lead to the buildup of pathogens and ammonia levels in the environment, increasing stress and health risks for poultry. Optimizing ventilation and litter management is crucial in both methods to minimize respiratory issues and improve overall flock well-being.

Choosing the Best Flock Management Strategy

All-in-all-out flock management enhances biosecurity by minimizing disease transmission through complete flock turnover and thorough sanitation between cycles, making it ideal for disease control and uniform growth. Continuous stocking allows for flexible production and constant market supply but increases the risk of disease persistence and inconsistent flock performance. Selecting the best strategy depends on farm capacity, disease risk tolerance, and market demand stability.

Related Important Terms

Staggered Placement

Staggered placement in poultry farming involves introducing new flocks at different times to maintain continuous production but increases the risk of disease transmission compared to the all-in-all-out system, where entire flocks are raised and removed simultaneously to break infection cycles. Implementing strict biosecurity measures is crucial in staggered placement to control pathogen spread, while all-in-all-out enhances flock health and uniformity by minimizing cross-contamination.

Multi-age Flock Dynamics

All-in-All-out flock management minimizes disease transmission and stress by synchronizing flock age, enabling effective sanitation between cycles, while continuous stocking with multi-age flocks increases risk of pathogen persistence and complicates disease control due to overlapping immunity stages. Managing multi-age flock dynamics requires careful biosecurity and vaccination strategies to mitigate health challenges inherent in continuous stocking systems.

Total Empty Period (TEP)

All-in-All-out flock management minimizes the Total Empty Period (TEP) by allowing complete barn sanitation and downtime between flocks, reducing disease risk and improving overall flock health and productivity. Continuous stocking increases TEP due to overlapping flock cycles, limiting effective cleaning and heightening exposure to pathogens.

Compartmentalized All-in-All-out

Compartmentalized All-in-All-out flock management involves rearing poultry in separate, isolated groups within distinct compartments to prevent disease transmission and enhance biosecurity. This method contrasts with continuous stocking by allowing thorough cleaning and disinfection between flocks, reducing pathogen buildup and promoting healthier bird growth.

Step-down Stocking

Step-down stocking, a variant of continuous stocking, involves gradually introducing new birds into different sections of a poultry house to minimize disease spread while maintaining consistent production cycles. This method contrasts with all-in-all-out systems by allowing overlapping flocks, but requires careful biosecurity and management to prevent cross-contamination between age groups.

Micro-flock Rotation

Micro-flock rotation in poultry farming leverages all-in-all-out management to reduce disease transmission by synchronizing flock placement and complete house emptying between cycles, optimizing biosecurity and environmental control. Continuous stocking, while allowing constant flock presence, increases pathogen persistence and complicates sanitation, making micro-flock rotation with all-in-all-out preferable for disease control and production efficiency.

All-in-Phase Cycling

All-in-All-out flock management in poultry farming involves raising a group of birds together from placement to removal, allowing thorough cleaning and disinfection between cycles to minimize disease risk and promote uniform growth. This method contrasts with Continuous Stocking, where birds of different ages coexist, increasing pathogen circulation and complicating biosecurity measures, but All-in-Phase Cycling maximizes production efficiency by synchronizing flock turnover and improving health outcomes.

Disease Pressure Interval

All-in-All-out flock management significantly reduces disease pressure intervals by allowing thorough cleaning and disinfection between batches, minimizing pathogen carryover. Continuous stocking maintains a constant presence of birds, increasing the risk of persistent infections and prolonged exposure to disease agents.

Biosecurity Transition Zone

The All-in-All-out system enhances biosecurity by allowing thorough cleaning and disinfection during the transition zone between flocks, minimizing pathogen carryover and disease risks. Continuous Stocking complicates maintaining a strict transition zone, increasing the likelihood of pathogen persistence and cross-contamination within the flock environment.

Flock Turnover Synchronization

All-in-All-out flock management synchronizes flock turnover by simultaneously removing all birds, enabling thorough cleaning and disease control before introducing a new batch, which reduces pathogen buildup and improves biosecurity. Continuous stocking lacks this synchronization, leading to overlapping age groups that increase disease transmission risk and complicate health monitoring and management efforts.

All-in-All-out vs Continuous Stocking for Flock Management Infographic

agridif.com

agridif.com