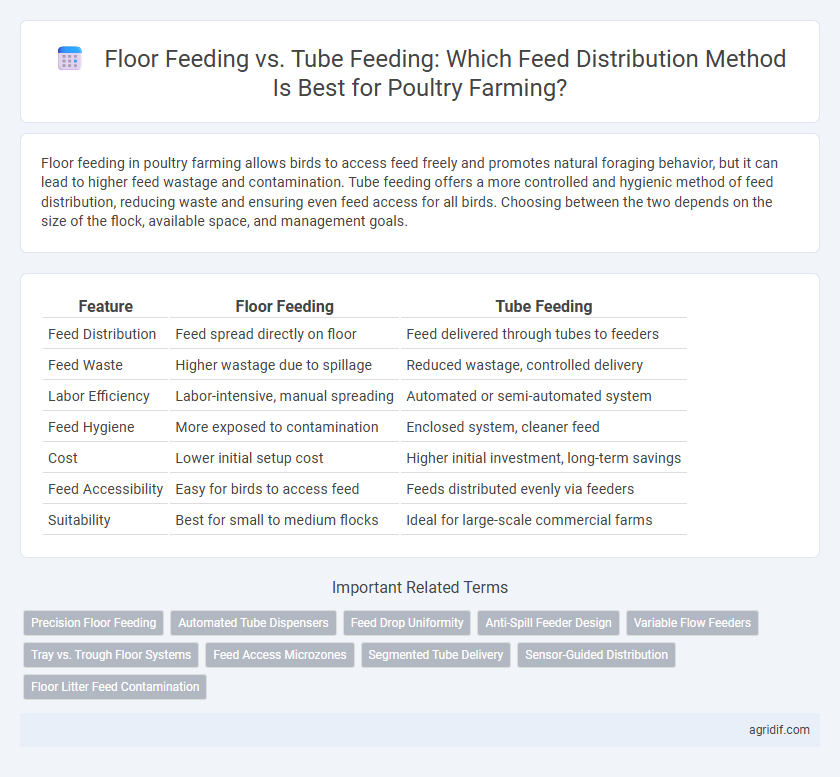

Floor feeding in poultry farming allows birds to access feed freely and promotes natural foraging behavior, but it can lead to higher feed wastage and contamination. Tube feeding offers a more controlled and hygienic method of feed distribution, reducing waste and ensuring even feed access for all birds. Choosing between the two depends on the size of the flock, available space, and management goals.

Table of Comparison

| Feature | Floor Feeding | Tube Feeding |

|---|---|---|

| Feed Distribution | Feed spread directly on floor | Feed delivered through tubes to feeders |

| Feed Waste | Higher wastage due to spillage | Reduced wastage, controlled delivery |

| Labor Efficiency | Labor-intensive, manual spreading | Automated or semi-automated system |

| Feed Hygiene | More exposed to contamination | Enclosed system, cleaner feed |

| Cost | Lower initial setup cost | Higher initial investment, long-term savings |

| Feed Accessibility | Easy for birds to access feed | Feeds distributed evenly via feeders |

| Suitability | Best for small to medium flocks | Ideal for large-scale commercial farms |

Introduction to Poultry Feeding Systems

Floor feeding and tube feeding represent two primary methods used in poultry feeding systems to distribute feed efficiently. Floor feeding involves scattering feed directly onto the poultry house floor, allowing birds to consume at their own pace, while tube feeding uses pipes or troughs to deliver feed precisely, minimizing waste and contamination. Tube feeding systems improve feed conversion rates and promote uniform growth by ensuring consistent access to feed, making them preferred in commercial poultry production.

Overview of Floor Feeding in Poultry Farming

Floor feeding in poultry farming involves spreading feed directly on the barn floor, allowing birds to access food freely while promoting natural foraging behavior. This method supports higher bird activity and can reduce feed wastage when managed properly, though it requires frequent cleaning to maintain hygiene. Floor feeding is often preferred in free-range or organic systems where natural feeding patterns are emphasized.

What is Tube Feeding for Poultry?

Tube feeding for poultry involves delivering feed directly through a network of tubes connected to feeders, ensuring uniform and controlled distribution of feed to each bird. This method reduces feed wastage by minimizing spillage compared to traditional floor feeding and supports consistent nutrition intake across the flock. Tube feeding systems are often automated, improving feeding efficiency and maintaining better hygiene in poultry houses.

Feed Distribution Efficiency: Floor vs Tube Feeding

Tube feeding in poultry farming offers higher feed distribution efficiency by delivering precise amounts of feed directly to feeding areas, minimizing spillage and waste compared to floor feeding. Floor feeding often results in uneven feed distribution and increased contamination risks due to feed exposure on the ground, lowering overall feed conversion ratios. Optimizing feed placement through tube systems enhances feed utilization, supports consistent bird growth, and reduces feed costs.

Impact on Flock Health and Hygiene

Floor feeding in poultry farming often leads to increased feed contamination from droppings and litter, raising the risk of disease and poor flock health. Tube feeding systems deliver feed directly to the feeding troughs, minimizing exposure to contaminants and promoting better hygiene. Improved hygiene through tube feeding reduces pathogen transmission, supporting overall flock health and enhancing production efficiency.

Cost Analysis: Floor Feeding vs Tube Feeding

Floor feeding in poultry farming generally incurs lower initial setup costs compared to tube feeding systems, which require investment in specialized equipment and installation. Operational expenses for floor feeding can be higher due to feed wastage and contamination risks, whereas tube feeding minimizes feed loss and improves efficiency, potentially reducing long-term costs. A cost analysis reveals that while floor feeding offers immediate savings, tube feeding systems provide better feed utilization, leading to greater profitability in large-scale operations.

Labor and Time Requirements

Floor feeding in poultry farming demands more labor-intensive efforts due to the manual spreading and frequent replenishment of feed, increasing time consumption during feeding cycles. Tube feeding systems automate feed distribution, significantly reducing labor costs and minimizing time spent on feeding tasks by delivering feed directly to specific locations. Efficient feed management through tube feeding supports scalability and consistent nutrition without the frequent oversight required in floor feeding methods.

Feed Wastage and Economic Loss

Floor feeding in poultry farming often leads to higher feed wastage due to spillage and contamination, increasing economic losses by reducing feed efficiency. Tube feeding systems minimize feed exposure, significantly lowering wastage and improving feed conversion ratios, resulting in cost savings on feed expenses. Implementing tube feeders can enhance overall profitability by maximizing feed utilization and reducing the financial impact of wasted feed.

Adaptability for Different Poultry Scales

Floor feeding offers high adaptability for small-scale poultry farms due to its minimal equipment requirements and ease of setup, suitable for free-range or backyard operations. Tube feeding systems excel in medium to large-scale poultry farms by providing uniform feed distribution, reducing waste, and allowing automation that supports high-density environments. Choosing between floor and tube feeding depends on farm size, infrastructure, and desired efficiency in feed management.

Recommendations for Optimal Feed Distribution

Tube feeding ensures precise feed distribution by minimizing waste and contamination, making it ideal for high-density poultry housing. Floor feeding supports natural foraging behavior but requires frequent cleaning to maintain feed hygiene and prevent disease. Combining tube feeding for concentrated nutrition and floor feeding for behavioral enrichment optimizes feed efficiency and bird health.

Related Important Terms

Precision Floor Feeding

Precision Floor Feeding optimizes feed distribution by delivering measured feed quantities directly to the poultry floor, enhancing feed accessibility and reducing wastage compared to traditional Tube Feeding methods. This targeted approach improves feed conversion ratios and supports uniform bird growth by minimizing feed segregation and ensuring consistent nutrient intake across the flock.

Automated Tube Dispensers

Automated tube feeders ensure precise, hygienic feed distribution by reducing spillage and contamination compared to traditional floor feeding methods, improving feed efficiency and bird health in poultry farming. These dispensers enable consistent delivery rates and limit feed waste, optimizing growth performance and operational labor costs.

Feed Drop Uniformity

Tube feeding in poultry farming ensures superior feed drop uniformity by delivering precise portions directly to feeders, minimizing wastage and promoting even distribution across flocks. In contrast, floor feeding often results in uneven feed scatter, increasing competition among birds and leading to inconsistent nutrient intake.

Anti-Spill Feeder Design

Anti-spill feeder designs in poultry farming significantly reduce feed wastage by preventing feed from spilling during both floor feeding and tube feeding methods. Tube feeding systems equipped with spill-proof mechanisms enhance feed distribution efficiency by minimizing contamination and maintaining optimal feed hygiene.

Variable Flow Feeders

Variable flow feeders in poultry farming enable precise control of feed distribution compared to traditional floor feeding and tube feeding methods, optimizing feed efficiency and reducing wastage. These feeders adjust feed flow rates based on bird demand, improving uniform growth and decreasing labor costs in large-scale operations.

Tray vs. Trough Floor Systems

Tray floor feeding systems distribute feed evenly on the barn floor, allowing birds free access but increasing feed spillage and waste. Trough floor feeding systems concentrate feed in raised or ground-level troughs, reducing waste and contamination while promoting cleaner feed access and efficient consumption.

Feed Access Microzones

Floor feeding creates larger feed access microzones, allowing multiple birds to feed simultaneously but increasing feed wastage due to spillage and contamination. Tube feeding concentrates feed delivery into smaller, controlled microzones, improving feed efficiency and reducing competition among birds for access.

Segmented Tube Delivery

Segmented tube delivery in poultry farming offers precise feed distribution directly to multiple feeding points, reducing feed wastage and ensuring uniform intake among birds. Compared to traditional floor feeding, this method enhances feed hygiene, minimizes labor costs, and improves overall flock performance by maintaining consistent feed availability.

Sensor-Guided Distribution

Sensor-guided distribution in poultry farming optimizes feed delivery by precisely controlling floor feeding systems to reduce waste and ensure uniform feed availability. Tube feeding enhanced with sensors allows automated, targeted dispensing that improves feed conversion ratios and promotes consistent flock growth.

Floor Litter Feed Contamination

Floor feeding in poultry farming often results in higher floor litter feed contamination due to feed spillage and accumulation of waste, increasing the risk of pathogen proliferation. Tube feeding minimizes feed wastage by delivering feed directly to feeders, significantly reducing contact between feed and litter, thereby lowering contamination levels and enhancing bird health.

Floor feeding vs Tube feeding for feed distribution Infographic

agridif.com

agridif.com