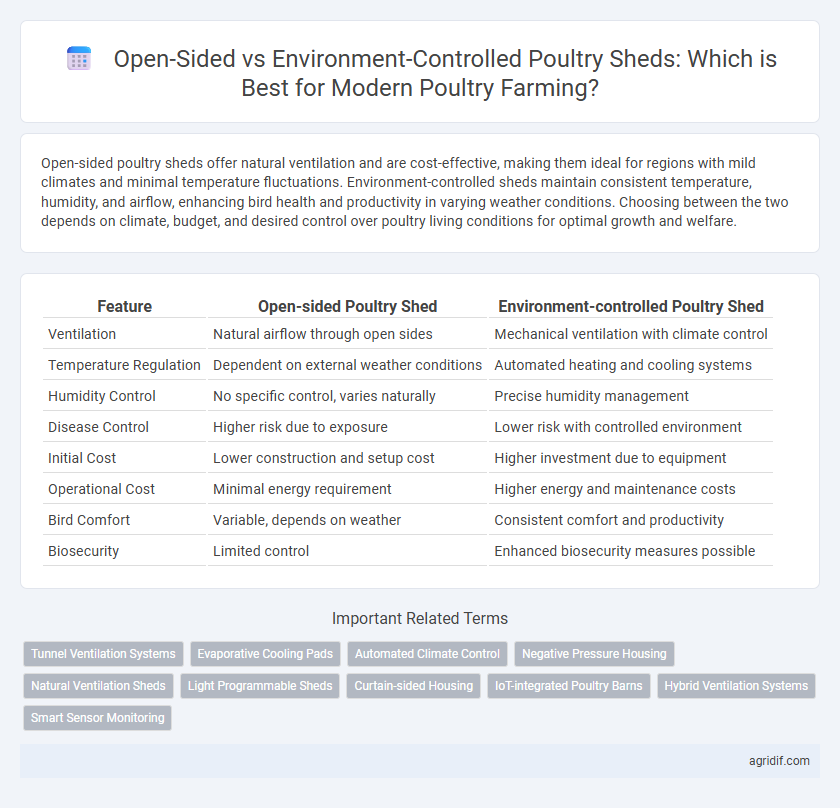

Open-sided poultry sheds offer natural ventilation and are cost-effective, making them ideal for regions with mild climates and minimal temperature fluctuations. Environment-controlled sheds maintain consistent temperature, humidity, and airflow, enhancing bird health and productivity in varying weather conditions. Choosing between the two depends on climate, budget, and desired control over poultry living conditions for optimal growth and welfare.

Table of Comparison

| Feature | Open-sided Poultry Shed | Environment-controlled Poultry Shed |

|---|---|---|

| Ventilation | Natural airflow through open sides | Mechanical ventilation with climate control |

| Temperature Regulation | Dependent on external weather conditions | Automated heating and cooling systems |

| Humidity Control | No specific control, varies naturally | Precise humidity management |

| Disease Control | Higher risk due to exposure | Lower risk with controlled environment |

| Initial Cost | Lower construction and setup cost | Higher investment due to equipment |

| Operational Cost | Minimal energy requirement | Higher energy and maintenance costs |

| Bird Comfort | Variable, depends on weather | Consistent comfort and productivity |

| Biosecurity | Limited control | Enhanced biosecurity measures possible |

Introduction to Poultry Shed Types

Open-sided poultry sheds offer natural ventilation and cost-effective construction, making them suitable for regions with mild climates and limited capital investment. Environment-controlled poultry sheds use advanced systems like fans, heaters, and humidifiers to maintain optimal temperature and humidity levels, enhancing bird health and productivity in varied climatic conditions. Choosing between these shed types depends on factors such as climate, budget, and desired production scale.

Defining Open-sided Poultry Sheds

Open-sided poultry sheds feature open walls or large openings that promote natural ventilation, crucial for maintaining air quality and temperature in hot climates. These structures rely on ambient airflow to reduce heat stress and humidity, making them energy-efficient compared to environment-controlled sheds. Suitable for regions with mild weather, open-sided sheds provide a cost-effective solution for poultry farmers aiming to optimize bird comfort and health.

Overview of Environment-controlled Poultry Sheds

Environment-controlled poultry sheds use automated systems to regulate temperature, humidity, ventilation, and lighting, ensuring optimal living conditions year-round. These sheds improve bird health, maximize productivity, and reduce mortality rates by maintaining stable environments despite external weather fluctuations. Advanced technologies such as sensors and climate control software are integral to minimizing energy consumption and enhancing overall operational efficiency.

Climate Control and Temperature Management

Open-sided poultry sheds rely on natural ventilation and ambient climate for temperature regulation, making them suitable for moderate climates but less efficient in extreme weather conditions. Environment-controlled sheds utilize advanced HVAC systems, enabling precise control over temperature, humidity, and airflow to optimize poultry health and productivity year-round. Effective climate control in environment-controlled sheds reduces heat stress and improves growth rates compared to the variable conditions in open-sided structures.

Ventilation and Air Quality Differences

Open-sided poultry sheds rely on natural ventilation through large openings, promoting constant airflow but offering limited control over temperature and humidity, which can vary with external weather conditions. Environment-controlled poultry sheds utilize mechanical ventilation systems with sensors and fans to precisely regulate air quality, temperature, and humidity, optimizing bird health and productivity. Effective air exchange rates in environment-controlled systems reduce ammonia levels and airborne pathogens more efficiently compared to open-sided designs, enhancing overall poultry welfare.

Disease Control and Biosecurity Measures

Open-sided poultry sheds offer natural ventilation that helps reduce the buildup of airborne pathogens but pose challenges for controlling environmental exposure and disease vectors. Environment-controlled sheds maintain stable temperature and humidity levels, facilitating stringent biosecurity protocols and minimizing disease spread through controlled airflow and restricted access. Effective disease control requires integrating these biosecurity measures, such as disinfection stations and controlled personnel movement, tailored to the specific shed type.

Energy Efficiency and Operational Costs

Open-sided poultry sheds offer natural ventilation, significantly reducing energy consumption but may incur higher operational costs due to exposure to fluctuating weather conditions affecting bird health and growth. Environment-controlled poultry sheds use advanced HVAC systems and insulation to maintain optimal temperatures, leading to consistent production rates and energy efficiency despite higher initial investments. Balancing energy efficiency with operational costs depends on regional climate, flock size, and production goals, making environment-controlled sheds more cost-effective in extreme weather zones.

Impact on Poultry Growth and Productivity

Open-sided poultry sheds provide natural ventilation and lower construction costs but expose birds to temperature fluctuations, potentially slowing growth and reducing productivity. Environment-controlled sheds maintain optimal temperature, humidity, and air quality, enhancing feed conversion rates and promoting consistent weight gain in poultry. Studies show environment-controlled systems can increase overall productivity by up to 20% compared to open-sided designs, due to improved bird comfort and health.

Initial Investment and Maintenance

Open-sided poultry sheds typically require a lower initial investment due to simpler construction materials and designs, making them cost-effective for small-scale operations. Environment-controlled sheds involve higher upfront costs for advanced ventilation, heating, and cooling systems but offer improved climate regulation, enhancing bird health and productivity. Maintenance costs for environment-controlled sheds are generally higher, driven by the need to service mechanical components and monitor environmental controls regularly.

Choosing the Right Poultry Shed for Your Farm

Selecting the right poultry shed is critical for optimizing bird health and productivity, with open-sided sheds offering superior ventilation and cost-efficiency in temperate climates. Environment-controlled sheds provide precise temperature, humidity, and lighting regulation, enhancing growth rates and reducing disease risk, particularly in extreme weather conditions. Balancing initial investment and operational costs against climatic demands helps determine the best shed type for sustainable poultry farming.

Related Important Terms

Tunnel Ventilation Systems

Tunnel ventilation systems in poultry sheds enhance air circulation by drawing air through open-sided designs or controlled environment enclosures, optimizing temperature and air quality for bird health and productivity. Environment-controlled sheds equipped with tunnel ventilation provide precise climate regulation, reducing heat stress and improving feed conversion rates compared to traditional open-sided poultry houses.

Evaporative Cooling Pads

Open-sided poultry sheds combined with evaporative cooling pads enhance ventilation and maintain optimal temperature by maximizing airflow, reducing heat stress in birds more effectively than static airflow systems. Environment-controlled sheds integrate advanced evaporative cooling pads with automated climate regulation, delivering precise humidity and temperature control for improved poultry health and productivity.

Automated Climate Control

Automated climate control in environment-controlled poultry sheds ensures precise regulation of temperature, humidity, and ventilation, optimizing bird health and productivity compared to open-sided structures. This technology reduces energy costs by adjusting conditions in real-time, minimizing stress and disease risks while enhancing feed conversion efficiency.

Negative Pressure Housing

Open-sided poultry sheds rely on natural ventilation but can suffer from inconsistent airflow and temperature, increasing risks of heat stress and disease. Negative pressure environment-controlled housing maintains stable air quality and temperature by using exhaust fans to create a controlled airflow, enhancing bird health and productivity.

Natural Ventilation Sheds

Natural ventilation sheds, commonly used in open-sided poultry farming, rely on airflow through large openings to regulate temperature and humidity, promoting bird comfort without mechanical systems. These sheds reduce energy costs and enhance air quality but may face challenges in extreme weather conditions compared to environment-controlled poultry houses.

Light Programmable Sheds

Open-sided poultry sheds maximize natural ventilation and light exposure, promoting healthier bird growth but limiting precise control over environmental factors. Environment-controlled, light programmable sheds enable optimized light cycles and temperature, enhancing poultry productivity and welfare through automation and real-time adjustments.

Curtain-sided Housing

Curtain-sided housing in poultry farming offers a flexible ventilation option, combining the benefits of open-sided sheds with enhanced environmental control by allowing adjustable airflow based on weather conditions. This system optimizes bird comfort and productivity by reducing heat stress and improving air quality compared to fully open or strictly environment-controlled sheds.

IoT-integrated Poultry Barns

Open-sided poultry sheds offer natural ventilation but lack precise climate control, often leading to inconsistent conditions that can affect bird health and productivity. Environment-controlled poultry barns integrated with IoT technology enable real-time monitoring and automated regulation of temperature, humidity, and air quality, optimizing growth conditions and enhancing operational efficiency.

Hybrid Ventilation Systems

Hybrid ventilation systems in poultry sheds combine open-sided natural airflow with mechanical environment-controlled features, optimizing air quality and temperature regulation to enhance bird health and productivity. These systems balance energy efficiency and environmental adaptability by automatically adjusting ventilation rates based on real-time climatic conditions and bird comfort needs.

Smart Sensor Monitoring

Open-sided poultry sheds offer natural ventilation but lack precision in climate control, while environment-controlled sheds utilize smart sensor monitoring to optimize temperature, humidity, and air quality, enhancing bird health and productivity. Smart sensors enable real-time data collection and automated adjustments, reducing energy usage and minimizing disease risks through improved environmental stability.

Open-sided vs Environment-controlled for poultry sheds Infographic

agridif.com

agridif.com