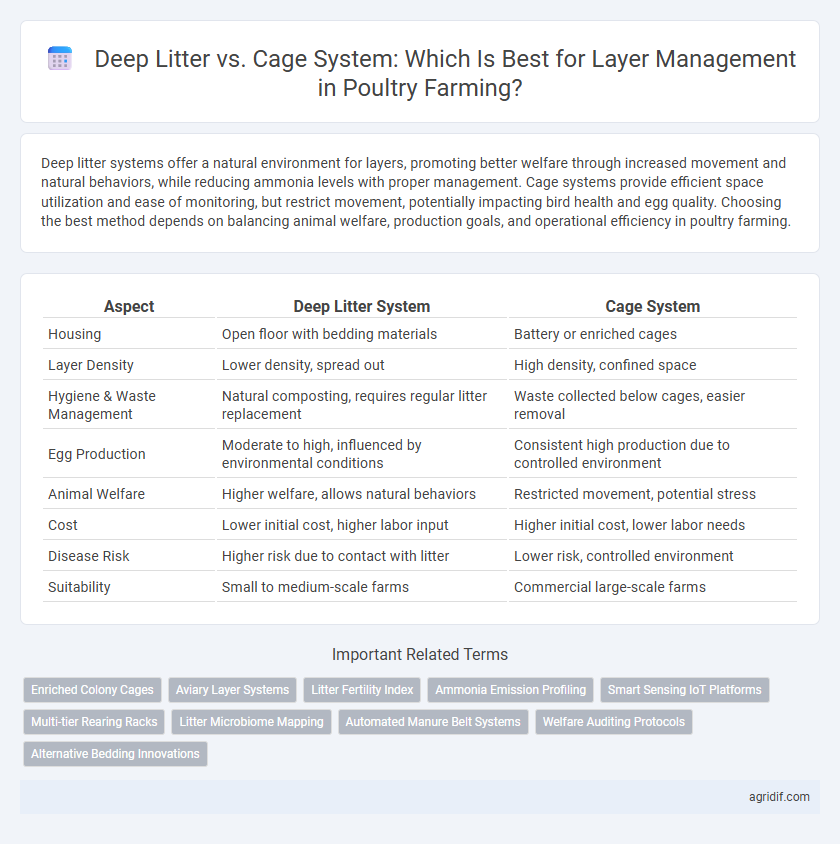

Deep litter systems offer a natural environment for layers, promoting better welfare through increased movement and natural behaviors, while reducing ammonia levels with proper management. Cage systems provide efficient space utilization and ease of monitoring, but restrict movement, potentially impacting bird health and egg quality. Choosing the best method depends on balancing animal welfare, production goals, and operational efficiency in poultry farming.

Table of Comparison

| Aspect | Deep Litter System | Cage System |

|---|---|---|

| Housing | Open floor with bedding materials | Battery or enriched cages |

| Layer Density | Lower density, spread out | High density, confined space |

| Hygiene & Waste Management | Natural composting, requires regular litter replacement | Waste collected below cages, easier removal |

| Egg Production | Moderate to high, influenced by environmental conditions | Consistent high production due to controlled environment |

| Animal Welfare | Higher welfare, allows natural behaviors | Restricted movement, potential stress |

| Cost | Lower initial cost, higher labor input | Higher initial cost, lower labor needs |

| Disease Risk | Higher risk due to contact with litter | Lower risk, controlled environment |

| Suitability | Small to medium-scale farms | Commercial large-scale farms |

Overview of Layer Management Systems

Layer management systems in poultry farming primarily include deep litter and cage systems, each impacting bird welfare, productivity, and environmental control differently. Deep litter systems allow hens to exhibit natural behaviors such as scratching and dust bathing, promoting better welfare but requiring more space and labor for manure management. Cage systems optimize space utilization and egg collection efficiency, improve biosecurity, and facilitate disease control, but often restrict natural behaviors and may raise animal welfare concerns.

Introduction to Deep Litter System

The deep litter system for layer management involves using a thick bedding layer composed of materials like wood shavings, rice hulls, or straw to absorb moisture and facilitate natural scratching behavior. This method promotes better welfare by allowing hens to express innate behaviors and reduces ammonia buildup through microbial decomposition. Deep litter systems generally offer lower setup and maintenance costs compared to intensive cage systems while improving environmental enrichment and litter quality.

Introduction to Cage System

The cage system for layer management involves housing hens in individual or group cages that facilitate controlled feeding, egg collection, and hygiene maintenance. This method enhances production efficiency by optimizing space and reducing disease transmission compared to deep litter systems. Cage systems also improve egg quality through reduced contact with manure and allow easier monitoring of bird health.

Housing Requirements for Each System

Deep litter systems require spacious, well-ventilated housing with ample flooring covered by absorbent materials like wood shavings to promote bird comfort and waste decomposition. Cage systems demand compact, elevated cages made from galvanized steel or plastic, ensuring easy cleaning, efficient manure removal, and controlled environmental conditions. Proper lighting, temperature control, and biosecurity measures are essential for both systems, tailored to optimize layer health and production.

Feed and Water Management Differences

Deep litter systems allow for more flexible feed placement and natural foraging behavior, resulting in potentially lower feed wastage compared to cage systems. In cage systems, feed and water are delivered through automated troughs and nipples, ensuring precise intake control but limiting natural feeding behavior. Effective feed and water management in deep litter systems requires regular cleaning and monitoring to prevent contamination, whereas cage systems offer easier sanitation and reduced risk of feed and water contamination.

Health and Disease Control: Deep Litter vs Cage

Deep litter systems promote natural behaviors and improve bird welfare but may increase exposure to pathogens in accumulated manure, necessitating rigorous litter management to prevent respiratory and coccidiosis outbreaks. Cage systems minimize contact with feces, reducing risks of parasitic infestations and some bacterial infections, but can cause stress-related immunosuppression leading to other health issues. Effective disease control in both systems requires tailored biosecurity measures, regular health monitoring, and appropriate vaccination protocols to maintain flock health and productivity.

Egg Production Efficiency Comparison

Deep litter systems for layer management promote natural behaviors and reduce stress, often resulting in higher egg production efficiency compared to cage systems. Cage systems, while enabling better disease control and uniform feeding, may limit bird movement, potentially impacting overall egg yield negatively. Studies indicate that layers housed in deep litter environments can achieve improved egg weight and shell quality, enhancing market value alongside production rates.

Labor and Cost Considerations

Deep litter systems in poultry farming typically require less initial investment in infrastructure compared to cage systems, making them more cost-effective for small to medium-sized operations. Labor demands are higher due to daily management tasks such as litter turning and cleaning, but these activities promote natural behaviors and can enhance bird welfare. Cage systems reduce labor needs through automated feeding and waste management but involve higher capital costs and potential long-term expenses related to health issues and bird stress.

Animal Welfare and Ethical Concerns

Deep litter systems in poultry farming provide layers with natural behaviors like dust bathing and perching, promoting better animal welfare compared to cage systems that restrict movement and natural instincts. Cage systems, often criticized for ethical concerns, limit space and cause stress, leading to higher incidences of bone fractures and feather loss. Choosing deep litter enhances ethical standards and aligns with welfare certifications by supporting more humane, enriched environments for laying hens.

Choosing the Best System for Your Farm

Selecting the optimal layer management system for poultry farming hinges on factors such as farm size, labor availability, and animal welfare priorities. Deep litter systems offer advantages in natural behavior expression and lower initial costs, while cage systems enhance space efficiency and disease control. Evaluating environmental impact, production goals, and regulatory compliance ensures alignment with sustainable and profitable poultry operations.

Related Important Terms

Enriched Colony Cages

Enriched colony cages offer improved welfare by providing layers with perches, nests, and more space compared to traditional cage systems, enhancing natural behaviors and egg production efficiency. Deep litter systems promote natural foraging and dust bathing but often face challenges in manure management and disease control, making enriched colony cages a balanced approach for sustainable layer management.

Aviary Layer Systems

Aviary layer systems combine elements of deep litter and cage systems by providing hens with multi-level perches, nesting areas, and litter floors, enhancing natural behaviors and welfare compared to conventional caged layers. These systems improve egg production quality and bird health by promoting more movement, better air quality, and reduced stress levels in commercial poultry farms.

Litter Fertility Index

The Deep Litter system enhances the Litter Fertility Index by promoting microbial activity and organic matter decomposition, resulting in nutrient-rich manure beneficial for soil amendment. In contrast, the Cage System produces drier, less biologically active waste, leading to lower fertility levels and reduced value for agricultural reuse.

Ammonia Emission Profiling

Deep litter systems in poultry farming generate higher ammonia emissions due to the accumulation of manure and bedding materials, leading to increased volatilization of ammonia gases. Cage systems for layer management confine waste more effectively, resulting in lower ammonia emission profiles that contribute to improved air quality and reduced respiratory stress in hens.

Smart Sensing IoT Platforms

Smart Sensing IoT platforms enhance layer management in both Deep Litter and Cage Systems by providing real-time monitoring of environmental parameters, feed intake, and hen behavior, optimizing productivity and welfare. These technologies enable precise control over temperature, humidity, and air quality, reducing disease risks and improving egg quality in poultry farming operations.

Multi-tier Rearing Racks

Multi-tier rearing racks in deep litter systems maximize space efficiency while promoting natural behaviors and improved welfare for layers through bedding management and waste absorption. Cage systems, by contrast, restrict movement and often require less floor space but may compromise hen health and egg quality due to limited environmental enrichment.

Litter Microbiome Mapping

Deep litter systems in poultry farming promote a diverse and dynamic litter microbiome, enhancing nutrient recycling and pathogen suppression compared to the more sterile and restricted cage systems. Microbiome mapping reveals that deep litter houses beneficial microbial communities crucial for disease resistance and improved layer health, which are significantly less complex in cage environments.

Automated Manure Belt Systems

Automated manure belt systems in poultry farming enhance sanitation and reduce labor in both deep litter and cage systems by efficiently removing waste from layer houses. These systems minimize ammonia levels, improve bird welfare, and boost egg production by providing a cleaner environment compared to traditional deep litter methods.

Welfare Auditing Protocols

Deep litter systems in layer management provide enhanced welfare auditing opportunities by allowing assessment of natural behaviors like dust bathing and foraging, which are limited in cage systems. Welfare auditing protocols in cage systems emphasize space allowance, perching, and feeder access, focusing on physical health metrics, whereas deep litter audits prioritize litter quality, air quality, and environmental enrichment to ensure holistic well-being.

Alternative Bedding Innovations

Innovative alternative bedding materials such as rice hulls, coconut coir, and shredded paper in deep litter systems enhance moisture absorption and reduce ammonia levels, outperforming traditional cage systems that limit natural behaviors but offer easier waste management. These sustainable solutions improve hen welfare by promoting dust bathing and natural foraging, leading to higher egg quality and reduced environmental impact compared to conventional cage housing.

Deep Litter vs Cage System for Layer Management Infographic

agridif.com

agridif.com