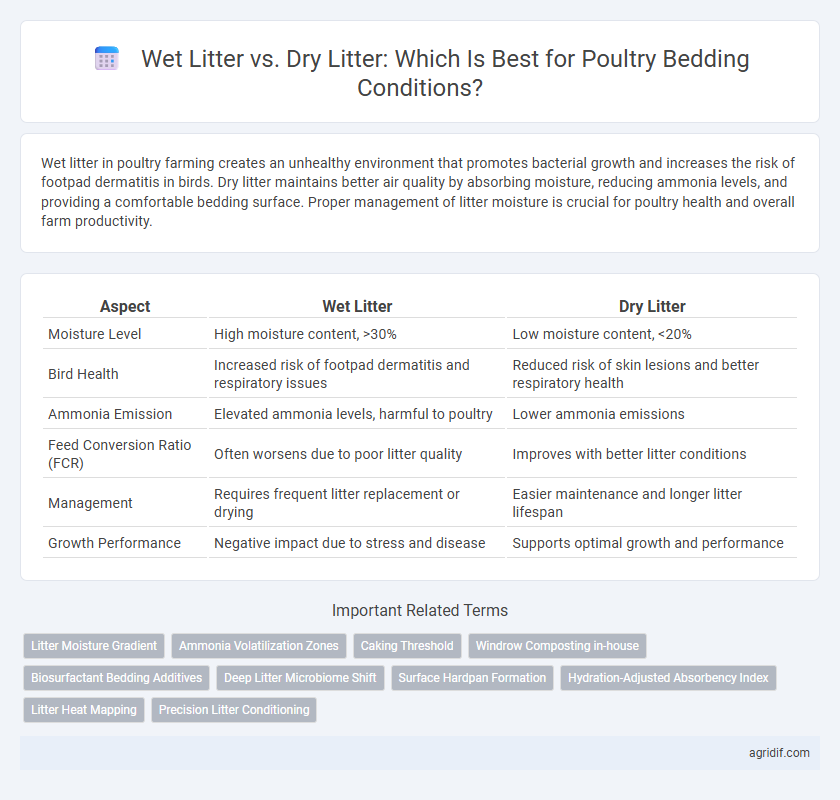

Wet litter in poultry farming creates an unhealthy environment that promotes bacterial growth and increases the risk of footpad dermatitis in birds. Dry litter maintains better air quality by absorbing moisture, reducing ammonia levels, and providing a comfortable bedding surface. Proper management of litter moisture is crucial for poultry health and overall farm productivity.

Table of Comparison

| Aspect | Wet Litter | Dry Litter |

|---|---|---|

| Moisture Level | High moisture content, >30% | Low moisture content, <20% |

| Bird Health | Increased risk of footpad dermatitis and respiratory issues | Reduced risk of skin lesions and better respiratory health |

| Ammonia Emission | Elevated ammonia levels, harmful to poultry | Lower ammonia emissions |

| Feed Conversion Ratio (FCR) | Often worsens due to poor litter quality | Improves with better litter conditions |

| Management | Requires frequent litter replacement or drying | Easier maintenance and longer litter lifespan |

| Growth Performance | Negative impact due to stress and disease | Supports optimal growth and performance |

Introduction to Poultry Litter Management

Effective poultry litter management is crucial for maintaining bird health and productivity. Wet litter increases the risk of bacterial infections, footpad dermatitis, and ammonia buildup, while dry litter supports a healthier environment by reducing pathogen growth and improving air quality. Proper ventilation, regular litter turning, and moisture control are essential practices to ensure optimal bedding conditions in poultry houses.

Understanding Wet Litter: Causes and Characteristics

Wet litter in poultry farming results from excess moisture due to poor ventilation, water spillage, or high humidity, creating ideal conditions for bacterial growth and ammonia release. This damp bedding compromises bird health by increasing the risk of footpad dermatitis and respiratory issues, while also degrading overall flock performance. Understanding these causes helps optimize bedding management for drier, healthier poultry environments.

Dry Litter Fundamentals in Poultry Houses

Dry litter in poultry houses is essential for optimal bird health, minimizing ammonia levels and reducing footpad dermatitis. Maintaining dry litter involves effective ventilation, controlled moisture from waterers, and regular bedding replacement to prevent microbial growth. Proper dry litter management enhances flock welfare and supports efficient growth performance in poultry farming.

Impact of Litter Moisture on Bird Health

High moisture levels in poultry litter create an ideal environment for pathogens such as bacteria and fungi, significantly increasing the risk of diseases like coccidiosis and footpad dermatitis in birds. Dry litter reduces ammonia emissions, which improves air quality and respiratory health, minimizing stress and promoting better growth performance. Maintaining optimal moisture content below 25% in bedding materials is crucial for preventing infections and ensuring overall flock productivity and welfare.

Disease Risks Associated with Wet Litter

Wet litter in poultry farming significantly increases the risk of bacterial infections such as Salmonella and E. coli, which thrive in moist, warm environments. Persistent wet bedding promotes ammonia buildup, leading to respiratory diseases like chronic bronchitis and increasing susceptibility to secondary infections. Maintaining dry litter reduces pathogen proliferation, minimizes footpad dermatitis, and supports overall flock health and productivity.

Benefits of Maintaining Dry Litter

Maintaining dry litter in poultry farming significantly reduces the risk of bacterial growth and ammonia buildup, promoting better respiratory health and reducing disease outbreaks in birds. Dry litter improves bird comfort by providing a clean, dry environment that supports natural behaviors like scratching and dust bathing, which enhances overall welfare and productivity. Additionally, dry litter facilitates easier management and waste removal, leading to improved hygiene and lower maintenance costs.

Strategies for Preventing Wet Litter in Poultry Farms

Effective strategies for preventing wet litter in poultry farms include maintaining optimal ventilation to reduce humidity levels and using absorbent bedding materials like wood shavings or rice hulls to promote dryness. Regular litter turning and timely removal of wet patches minimize ammonia buildup and bacterial growth, enhancing bird health and performance. Implementing precise water management systems and ensuring well-maintained drinkers prevent leaks, further reducing moisture accumulation in poultry house bedding.

Litter Material Choices and Their Absorbency

Choosing appropriate litter materials significantly impacts poultry health and productivity, with dry litter such as wood shavings, rice hulls, and chopped straw offering superior moisture absorption compared to wet litter types like sand or fine sawdust. High-absorbency materials reduce ammonia levels, minimize footpad dermatitis, and promote optimal bird comfort by maintaining a dry environment. Studies show that pine wood shavings absorb up to 50% more moisture than sand, enhancing litter management and reducing the risk of bacterial proliferation in poultry houses.

Environmental Effects of Wet vs Dry Litter Disposal

Wet litter disposal in poultry farming contributes significantly to ammonia emissions, increasing air pollution and posing health risks to both animals and farm workers. Dry litter, when disposed of properly, reduces harmful gas release and facilitates nutrient recycling as organic fertilizer, promoting sustainable agricultural practices. Managing moisture levels in bedding is crucial to minimizing environmental impact and enhancing soil and water quality through controlled waste decomposition.

Best Practices for Optimal Litter Conditions in Poultry Farming

Maintaining dry litter in poultry farming is essential to prevent ammonia buildup, reduce pathogen proliferation, and enhance bird health and growth performance. Best practices for optimal litter conditions include frequent monitoring of moisture levels, ensuring adequate ventilation, and using absorbent bedding materials like wood shavings or rice hulls. Implementing proper litter management techniques minimizes wet litter issues, promotes bird welfare, and improves overall farm productivity.

Related Important Terms

Litter Moisture Gradient

Litter moisture gradient significantly impacts poultry health and performance, with wet litter promoting ammonia production and higher risk of footpad dermatitis, while dry litter minimizes pathogen proliferation and improves bird welfare. Optimal bedding conditions maintain moisture content below 25%, ensuring adequate ventilation and frequent litter management to sustain a dry environment.

Ammonia Volatilization Zones

Wet litter in poultry farming significantly increases ammonia volatilization zones due to higher moisture content promoting microbial activity that breaks down uric acid into ammonia gas, leading to poor air quality and respiratory issues in birds. Dry litter reduces the extent of ammonia volatilization zones by limiting microbial degradation processes, thus maintaining healthier bedding conditions and improving poultry welfare and productivity.

Caking Threshold

Wet litter in poultry farming typically exceeds the caking threshold of 25-30% moisture content, leading to compacted bedding that fosters ammonia buildup, pathogens, and footpad dermatitis. Maintaining dry litter under this threshold promotes better air quality, bird comfort, and reduces the risk of caking-related health issues.

Windrow Composting in-house

Wet litter in poultry houses fosters harmful ammonia emissions and increased pathogenic risks, negatively impacting bird health and growth. Maintaining dry litter through in-house windrow composting accelerates microbial breakdown of manure, reduces moisture, and enhances air quality, supporting optimal turkey and chicken performance.

Biosurfactant Bedding Additives

Biosurfactant bedding additives improve moisture control in poultry litter by reducing wet litter conditions, enhancing absorbency and minimizing ammonia emissions, which promotes healthier bird environments. These additives support dry litter maintenance through natural antimicrobial properties, reducing pathogen load and improving overall flock welfare and productivity.

Deep Litter Microbiome Shift

Wet litter in poultry farming significantly alters the deep litter microbiome, promoting the proliferation of pathogenic bacteria such as Clostridium perfringens and increasing ammonia emissions, which deteriorate bird health and performance. In contrast, dry litter supports a more balanced microbial community dominated by beneficial microbes like Bacillus species, enhancing litter quality, reducing disease risk, and improving overall flock productivity.

Surface Hardpan Formation

Wet litter in poultry farming significantly accelerates surface hardpan formation, leading to compacted bedding that impedes moisture evaporation and promotes pathogen growth. Dry litter conditions maintain fluffiness and aeration, preventing hardpan development and supporting healthier poultry environments.

Hydration-Adjusted Absorbency Index

The Hydration-Adjusted Absorbency Index (HAAI) measures bedding's capacity to manage moisture, highlighting dry litter's superior ability to maintain optimal hydration levels and reduce ammonia buildup in poultry houses. Wet litter consistently demonstrates lower HAAI values, increasing risks of footpad dermatitis and respiratory issues in broiler production.

Litter Heat Mapping

Wet litter in poultry houses creates uneven heat distribution detected through litter heat mapping, promoting bacterial growth and increasing ammonia levels harmful to bird health. Dry litter maintains consistent thermal profiles, enhancing moisture control, reducing pathogens, and improving overall flock welfare and productivity.

Precision Litter Conditioning

Precision litter conditioning in poultry farming enhances bird health by maintaining optimal moisture levels, preventing wet litter that promotes bacterial growth and ammonia emissions. Employing advanced sensors and automated ventilation systems ensures dry bedding, improving air quality and reducing footpad dermatitis incidence.

Wet Litter vs Dry Litter for bedding conditions Infographic

agridif.com

agridif.com