Scalding in poultry processing involves dipping birds in hot water to loosen feathers, making plucking easier and preserving skin integrity, which is ideal for maintaining product quality. Skinning removes the skin entirely, resulting in a cleaner appearance but can increase the risk of meat damage and requires more skill to avoid contamination. Choosing between scalding and skinning depends on the desired final product, equipment availability, and processing efficiency in poultry farming.

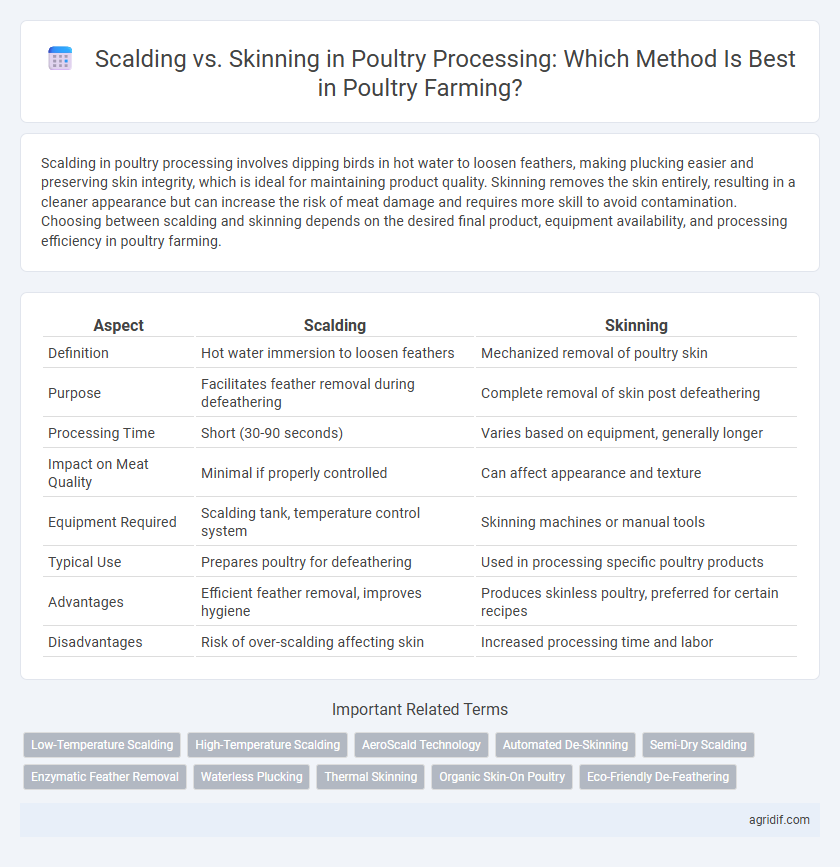

Table of Comparison

| Aspect | Scalding | Skinning |

|---|---|---|

| Definition | Hot water immersion to loosen feathers | Mechanized removal of poultry skin |

| Purpose | Facilitates feather removal during defeathering | Complete removal of skin post defeathering |

| Processing Time | Short (30-90 seconds) | Varies based on equipment, generally longer |

| Impact on Meat Quality | Minimal if properly controlled | Can affect appearance and texture |

| Equipment Required | Scalding tank, temperature control system | Skinning machines or manual tools |

| Typical Use | Prepares poultry for defeathering | Used in processing specific poultry products |

| Advantages | Efficient feather removal, improves hygiene | Produces skinless poultry, preferred for certain recipes |

| Disadvantages | Risk of over-scalding affecting skin | Increased processing time and labor |

Introduction to Poultry Processing Methods

Scalding and skinning are essential poultry processing methods used to prepare birds for further handling and consumption, each with distinct techniques and outcomes. Scalding involves immersing poultry in hot water between 50-60degC to loosen feathers without damaging the skin, optimizing feather removal efficiency and preserving the carcass integrity. Skinning removes the skin entirely, often for specific product requirements, affecting texture and appearance while impacting subsequent processing stages like seasoning and cooking.

Overview of Scalding in Poultry Processing

Scalding in poultry processing involves immersing birds in hot water, typically between 50degC and 60degC, to loosen feathers for easier removal during defeathering. This method enhances the efficiency of subsequent skinning and helps maintain the integrity of the skin, reducing damage compared to dry skinning techniques. Proper scalding parameters are critical to balancing feather removal with preserving meat quality and hygiene standards in commercial poultry operations.

Understanding Skinning as an Alternative Method

Skinning in poultry processing involves the manual or mechanical removal of feathers and skin without the use of hot water, reducing the risk of moisture retention and bacterial contamination. This method preserves meat texture and quality better than scalding, which uses hot water to loosen feathers but can penetrate the skin and affect flavor. Skinning offers an energy-efficient alternative for poultry processors aiming to maintain product integrity and extend shelf life.

Key Differences Between Scalding and Skinning

Scalding involves immersing poultry in hot water at temperatures between 130degF and 150degF to loosen feathers, whereas skinning refers to the mechanical or manual removal of the skin from the bird's carcass. Scalding preserves the skin for further processing, making it suitable for products like whole birds or skin-on cuts, while skinning removes the protective layer entirely, often used in deboned or skinless poultry products. The choice between scalding and skinning significantly impacts processing time, labor intensity, and end-product texture and appearance.

Impact on Meat Quality: Scalding vs Skinning

Scalding in poultry processing enhances meat tenderness by loosening feathers with minimal muscle damage, preserving juiciness and texture. Skinning removes the skin entirely, which can lead to moisture loss and a firmer meat texture but ensures a cleaner final product without feather remnants. The choice between scalding and skinning directly impacts the meat's sensory qualities, moisture retention, and overall consumer appeal.

Equipment and Tools Needed for Each Method

Scalding requires a controlled temperature water bath or tank along with thermometers and mechanical or manual feather pluckers to loosen and remove feathers efficiently. Skinning demands sharp, precise knives or automated skinning machines designed to separate the skin from the carcass without damaging the meat. Both methods rely on specific equipment tailored to optimize processing speed, maintain hygiene, and preserve meat quality in commercial poultry operations.

Labor and Time Efficiency Comparison

Scalding in poultry processing significantly reduces labor intensity by loosening feathers quickly, allowing for faster mechanical plucking, which enhances overall time efficiency. Skinning, although more precise and yielding higher-quality cuts, demands greater manual labor and longer processing times, making it less efficient for high-volume operations. Choosing scalding over skinning optimizes labor cost savings and accelerates throughput in commercial poultry farming.

Hygiene and Food Safety Considerations

Scalding in poultry processing effectively loosens feathers while maintaining the integrity of the skin, reducing the risk of bacterial contamination by preventing tears that harbor pathogens. Skinning removes the entire skin, which may eliminate surface bacteria but increases the risk of exposure to internal contaminants and cross-contamination during handling. Strict hygiene protocols and monitoring of microbial loads are essential in both methods to ensure food safety and minimize the risk of foodborne illnesses.

Suitability for Small-Scale and Large-Scale Operations

Scalding offers efficiency and uniformity ideal for large-scale poultry processing by facilitating easier feather removal, while skinning is better suited for small-scale operations where precision and minimizing skin damage are priorities. Small-scale farmers benefit from skinning due to lower equipment costs and greater control over carcass quality, whereas large-scale producers favor scalding for its speed and scalability. Choosing between scalding and skinning depends on operational volume, budget constraints, and desired product characteristics in poultry processing.

Choosing the Right Method for Your Poultry Farm

Selecting between scalding and skinning methods for poultry processing depends on the farm's production goals and bird types. Scalding is ideal for large-scale operations targeting smooth skin removal and maintaining carcass quality, while skinning suits farms emphasizing skin-on products or specialty poultry breeds. Evaluating factors like equipment costs, labor intensity, and end-product requirements ensures optimal processing efficiency and product appeal.

Related Important Terms

Low-Temperature Scalding

Low-temperature scalding in poultry processing maintains feather follicle integrity, reducing skin tears and improving carcass appearance compared to traditional high-temperature methods. This technique enhances overall meat quality by preserving collagen structure and minimizing microbial contamination risks during defeathering.

High-Temperature Scalding

High-temperature scalding in poultry processing involves immersing birds in water heated between 60degC to 66degC, effectively loosening feathers for easier removal while preserving skin integrity. This method enhances efficiency in commercial poultry farming by reducing defeathering time and minimizing skin damage compared to traditional skinning techniques.

AeroScald Technology

AeroScald technology revolutionizes poultry processing by providing an efficient scalding method that preserves skin quality while enhancing feather removal compared to traditional scalding and skinning techniques. Its advanced waterless or low-water system reduces cross-contamination risks, improves heat distribution, and enhances processing speed, making it a sustainable choice for high-volume poultry farms.

Automated De-Skinning

Automated de-skinning in poultry processing offers higher efficiency and consistency compared to traditional scalding methods by precisely removing feathers without damaging the skin, reducing labor costs and contamination risks. Modern machinery utilizes advanced sensors and mechanical techniques to optimize skin removal speed and quality, enhancing overall production throughput and product uniformity.

Semi-Dry Scalding

Semi-dry scalding in poultry processing uses minimal water and controlled heat to loosen feathers while preserving skin quality, reducing water usage compared to traditional wet scalding methods. This technique enhances carcass appearance and texture, making it a cost-effective and environmentally friendly choice for commercial poultry operations.

Enzymatic Feather Removal

Enzymatic feather removal in poultry processing offers a controlled and efficient alternative to traditional scalding and skinning methods, utilizing specific enzymes to break down feather follicles without damaging the skin. This technique reduces processing time, improves bird appearance, and minimizes water and energy consumption compared to conventional hot water scalding or mechanical plucking.

Waterless Plucking

Waterless plucking in poultry processing eliminates the need for scalding by using rubber fingers to remove feathers efficiently, preserving skin quality and reducing water consumption. This method enhances hygiene and product yield compared to traditional scalding and skinning techniques, aligning with sustainable poultry farming practices.

Thermal Skinning

Thermal skinning in poultry processing uses controlled high temperatures to efficiently separate the skin from the carcass, enhancing yield and maintaining meat quality compared to traditional scalding methods. This technique reduces bacterial contamination risk and improves processing speed by precisely targeting skin adhesion without damaging underlying tissues.

Organic Skin-On Poultry

Scalding preserves the natural skin structure and enhances feather removal efficiency, crucial for maintaining the quality of organic skin-on poultry by reducing mechanical damage and microbial contamination. Skinning, while useful for portioning, often compromises the protective skin layer and may negatively impact the organic poultry's texture and appearance, limiting consumer appeal.

Eco-Friendly De-Feathering

Scalding uses hot water to loosen feathers for easier removal, consuming significant energy and water, whereas skinning mechanically strips feathers, generating less wastewater and reducing environmental impact. Choosing skinning as an eco-friendly de-feathering method helps poultry processors lower resource consumption and supports sustainable farming practices.

Scalding vs Skinning for poultry processing Infographic

agridif.com

agridif.com