Mountages and Chandrika are two popular sericulture pets known for their cocoon spinning abilities. Mountages typically produce larger and more robust cocoons with a smoother texture, making them ideal for high-quality silk production. Chandrika, on the other hand, offers faster spinning rates and better adaptability to varying environmental conditions, which benefits large-scale silk farmers seeking efficiency.

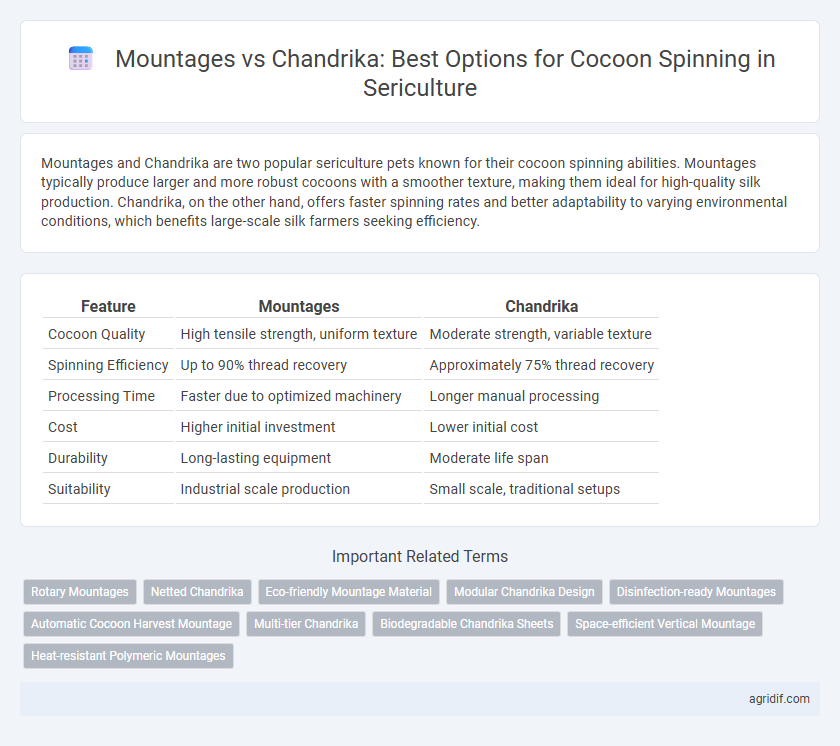

Table of Comparison

| Feature | Mountages | Chandrika |

|---|---|---|

| Cocoon Quality | High tensile strength, uniform texture | Moderate strength, variable texture |

| Spinning Efficiency | Up to 90% thread recovery | Approximately 75% thread recovery |

| Processing Time | Faster due to optimized machinery | Longer manual processing |

| Cost | Higher initial investment | Lower initial cost |

| Durability | Long-lasting equipment | Moderate life span |

| Suitability | Industrial scale production | Small scale, traditional setups |

Introduction to Cocoon Spinning in Sericulture

Cocoon spinning in sericulture involves the careful management of silkworm larvae to produce high-quality silk fibers. Mountages are natural or artificial frameworks used to support the structure of cocoons during spinning, allowing optimal airflow and preventing deformation, while Chandrika refers to specialized trays or mats facilitating uniform cocoon formation. The choice between Mountages and Chandrika impacts silk yield and quality, with Mountages favoring traditional methods and Chandrika offering enhanced control over spinning conditions.

What are Mountages? An Overview

Mountages are frameworks used in sericulture to support the cocoon spinning process, providing an optimal environment for silkworms to spin their cocoons efficiently. These structures are designed to maximize silk yield by ensuring proper airflow, temperature, and humidity control during cocoon formation. Mountages contrast with Chandrika systems by emphasizing a more stable and spacious setup for enhanced cocoon quality and uniformity.

Understanding Chandrika in Cocoon Spinning

Chandrika is a traditional spinning tool used in sericulture for processing raw silk from cocoons, offering precision and efficiency in extracting fibers. Compared to Mountages, which are primarily frame structures for reeling silk, Chandrika facilitates manual control during cocoon spinning, enhancing silk quality by reducing fiber breakage. Its design allows for smooth unwinding of silk threads, crucial for maintaining fiber strength and producing high-grade silk yarn.

Key Differences Between Mountages and Chandrika

Mountages provide a controlled environment with optimized temperature and humidity for cocoon spinning, enhancing filament quality and yield. Chandrika, typically a more natural or traditional setup, offers less precise environmental control, which can affect cocoon uniformity and filament consistency. Key differences lie in environmental regulation, cocoon protection, and scalability, with Mountages favoring industrial-scale sericulture and Chandrika suited for small-scale or traditional practices.

Advantages of Using Mountages

Mountages in sericulture offer superior advantages over Chandrika for cocoon spinning due to their enhanced ventilation and optimal spacing, which results in better aeration and reduced disease incidence. The design of mountages facilitates uniform cocoon development and easier harvesting, increasing overall productivity and quality of silk fibers. Their durability and ease of maintenance further contribute to cost efficiency and sustainable sericulture practices.

Benefits of Chandrika for Cocoon Spinning

Chandrika offers superior moisture retention and enhanced fiber strength, making it ideal for cocoon spinning in sericulture. Its unique composition promotes uniform cocoon texture and reduces spinning time compared to Mountages. These benefits result in higher-quality silk yarn with improved tensile properties and economic efficiency for sericulture producers.

Impact on Cocoon Quality: Mountages vs Chandrika

Mountages demonstrate superior cocoon spinning quality compared to Chandrika, resulting in stronger and more uniform silk fibers. The microclimate control in Mountages reduces moisture variability, minimizing defects and enhancing filament length. Chandrika, while cost-effective, often produces cocoons with irregular shapes and lower tensile strength, impacting overall silk yield and quality.

Cost and Maintenance Considerations

Mountages require less initial investment compared to Chandrika due to simpler construction, reducing upfront costs for cocoon spinning in sericulture. Chandrika involves higher maintenance expenses because of its intricate design and the need for regular cleaning to ensure optimal airflow and cocoon protection. Farmers seeking cost-effective solutions often favor mountages for their low maintenance demands and affordability in the cocoon spinning process.

Farmer Preferences: Mountages vs Chandrika

Farmers engaged in sericulture show a distinct preference for Mountages over Chandrika when it comes to cocoon spinning due to Mountages' higher efficiency and durability. Mountages offer better resistance to environmental factors, resulting in a more consistent yield and reduced spinning time, which is crucial for optimizing harvest cycles. In contrast, Chandrika, while cost-effective, tends to have lower durability and requires more frequent replacements, influencing farmer choices towards Mountages for sustainable sericulture practices.

Future Trends in Cocoon Spinning Devices

Mountages and Chandrika represent two prominent technologies in cocoon spinning, with Mountages offering automated efficiency while Chandrika maintains traditional manual precision. Future trends indicate a shift towards hybrid systems combining Mountages' mechanization with Chandrika's quality control to optimize silk yield and thread strength. Integration of IoT sensors and AI-driven monitoring in these devices is expected to revolutionize sericulture by enhancing spinning accuracy and reducing labor costs.

Related Important Terms

Rotary Mountages

Rotary mountages in sericulture provide superior support for cocoon spinning compared to Chandrika frames, enabling uniform airflow and enhanced cocoon quality. The efficient design of rotary mountages promotes optimal silkworm movement and reduces wastage by facilitating continuous spinning cycles.

Netted Chandrika

Netted Chandrika offers superior cocoon spinning efficiency compared to Mountages, enhancing silk filament uniformity and yield during sericulture. Its innovative netted design reduces filament breakage and improves aeration, promoting higher quality silk production.

Eco-friendly Mountage Material

Mountages made from bamboo and jute offer eco-friendly alternatives for cocoon spinning compared to Chandrika, which is primarily composed of synthetic materials. These natural Mountage materials enhance sustainability by reducing plastic waste and promoting biodegradable options in sericulture production.

Modular Chandrika Design

Modular Chandrika design in sericulture offers superior control over cocoon spinning compared to traditional Mountages, enhancing airflow regulation and uniform heat distribution to improve filament quality and yield. Its scalable, customizable modules enable efficient space utilization and maintenance, making it a preferred choice for modern silk production facilities focused on optimizing sericulture outcomes.

Disinfection-ready Mountages

Disinfection-ready Mountages in sericulture offer superior hygiene control and enhanced cocoon spinning efficiency compared to traditional Chandrika trays, reducing disease transmission and improving larval health. These Mountages facilitate uniform air circulation and ease of sterilization, resulting in higher quality silk yield and lower mortality rates during the spinning phase.

Automatic Cocoon Harvest Mountage

Automatic Cocoon Harvest Mountages in sericulture enhance efficiency by precisely controlling the spinning process, reducing labor costs and increasing silk quality compared to traditional Chandrika methods. These mountages integrate advanced sensors and automated mechanisms to optimize cocoon collection, minimizing damage and ensuring higher yield in silk production.

Multi-tier Chandrika

Multi-tier Chandrika systems outperform traditional Mountages in cocoon spinning by providing increased space efficiency and improved airflow, which enhances silkworm comfort and silk yield. The vertical design of Multi-tier Chandrika allows for higher cocoon density per unit area, optimizing sericulture productivity and resource utilization.

Biodegradable Chandrika Sheets

Biodegradable Chandrika sheets offer a sustainable alternative to traditional Mountages for cocoon spinning, enhancing environmental safety and reducing plastic waste in sericulture. These sheets ensure optimal cocoon formation by providing breathable, moisture-retentive surfaces that improve silk quality and ease of cocoon harvesting.

Space-efficient Vertical Mountage

Space-efficient vertical mountages in sericulture optimize cocoon spinning by maximizing filament output within limited areas, offering improved aeration and ease of maintenance compared to traditional Chandrika frames. Mountages facilitate higher cocoon density and enhanced silk filament quality through uniform silkworm positioning, crucial for commercial sericulture productivity.

Heat-resistant Polymeric Mountages

Mountages made from heat-resistant polymeric materials offer superior durability and thermal stability compared to Chandrika for cocoon spinning in sericulture, ensuring consistent cocoon integrity under varying temperature conditions. These advanced polymeric mountages reduce cocoon damage and enhance silk thread quality by maintaining optimal environmental control during the spinning process.

Mountages vs Chandrika for Cocoon Spinning Infographic

agridif.com

agridif.com