Cocoon harvesting involves carefully collecting silk cocoons at the peak of maturity to ensure maximum silk quality and length. Cocoon stifling is the process of killing the pupae inside the cocoons to prevent them from emerging, which preserves the silk thread but requires precise temperature control to avoid damaging the fibers. Effective cocoon processing depends on balancing timely harvesting with proper stifling techniques to optimize silk yield and maintain fiber strength for sericulture pet projects.

Table of Comparison

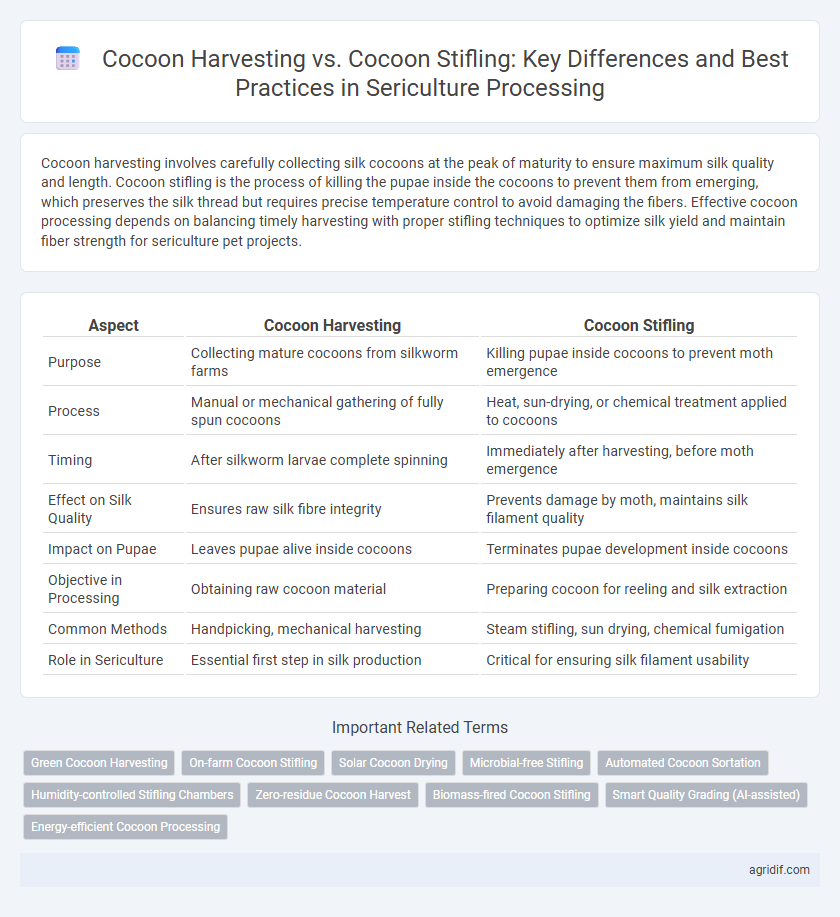

| Aspect | Cocoon Harvesting | Cocoon Stifling |

|---|---|---|

| Purpose | Collecting mature cocoons from silkworm farms | Killing pupae inside cocoons to prevent moth emergence |

| Process | Manual or mechanical gathering of fully spun cocoons | Heat, sun-drying, or chemical treatment applied to cocoons |

| Timing | After silkworm larvae complete spinning | Immediately after harvesting, before moth emergence |

| Effect on Silk Quality | Ensures raw silk fibre integrity | Prevents damage by moth, maintains silk filament quality |

| Impact on Pupae | Leaves pupae alive inside cocoons | Terminates pupae development inside cocoons |

| Objective in Processing | Obtaining raw cocoon material | Preparing cocoon for reeling and silk extraction |

| Common Methods | Handpicking, mechanical harvesting | Steam stifling, sun drying, chemical fumigation |

| Role in Sericulture | Essential first step in silk production | Critical for ensuring silk filament usability |

Introduction to Cocoon Processing in Sericulture

Cocoon processing in sericulture involves two critical steps: cocoon harvesting and cocoon stifling, each essential for optimal silk production. Cocoon harvesting entails carefully collecting mature cocoons to ensure maximum silk filament length and quality, while cocoon stifling is the process of killing the pupae inside the cocoons to prevent moth emergence, preserving the cocoon's integrity. Proper execution of these steps directly influences the efficiency of silk reeling and the overall yield of high-grade silk fibers.

Overview of Cocoon Harvesting Techniques

Cocoon harvesting techniques in sericulture significantly influence silk quality and yield, with methods such as green cocoon harvesting enabling live pupae preservation for seed production, while mature cocoon harvesting targets maximum silk extraction. Timely harvesting is critical to prevent larval damage and ensure optimal filament length, often involving handpicking or mechanical methods depending on scale and geography. Efficient harvesting sets the foundation for downstream processes like cocoon stifling, which stabilizes silk fibers by terminating pupal development through controlled heat treatments.

Cocoon Stifling: Methods and Importance

Cocoon stifling is a critical process in sericulture that involves killing the pupa inside the cocoon to prevent damage to the silk filament during reeling. Common stifling methods include hot air drying, sun drying, and chemical treatments such as phenol or formalin, each chosen based on environmental conditions and required silk quality. Proper stifling enhances silk filament length and strength, directly impacting the efficiency and quality of cocoon processing in silk production.

Key Differences Between Cocoon Harvesting and Stifling

Cocoon harvesting involves collecting mature cocoons directly from silkworms, ensuring maximum silk quality and uniformity, whereas cocoon stifling refers to the process of killing the pupae inside the cocoons to prevent moth emergence and preserve silk integrity. Harvesting timing affects raw silk yield and filament length, while stifling methods like hot air, steam, or chemical treatments impact fiber strength and texture. Understanding these key differences is critical for optimizing silk production efficiency and maintaining high-quality sericulture outputs.

Impact on Silk Quality: Harvesting vs. Stifling

Cocoon harvesting preserves the natural integrity of silk fibers, resulting in higher tensile strength and luster, essential for premium silk quality. In contrast, cocoon stifling, which kills pupae through heat or chemicals, ensures timely processing but may reduce silk fiber elasticity and brightness due to thermal or chemical exposure. Optimal silk quality depends on balancing prompt harvesting with careful stifling methods to minimize fiber damage and maintain silk's desirable physical properties.

Timing and Handling: Best Practices for Cocoon Harvesting

Optimal cocoon harvesting occurs when pupation is complete but before adult moth emergence, ensuring maximum silk quality and yield. Timely and careful handling minimizes damage and contamination, preserving cocoon integrity for efficient stifling processes such as hot air, sunlight, or chemical treatments. Adhering to precise timing improves fiber strength and reduces economic losses in sericulture operations.

Stifling Methods: Traditional vs. Modern Technologies

Cocoon stifling methods significantly impact silk quality and yield, with traditional techniques such as sun drying and hot water immersion relying on manual processes that risk uneven temperature control and increased contamination. Modern technologies utilize controlled environment chambers and steam sterilization to ensure uniform heat distribution, reducing pupal mortality and preserving fibroin integrity for superior fiber output. Advanced stifling systems optimize processing efficiency, minimize silk waste, and enhance overall sericulture profitability through precision temperature and humidity regulation.

Economic Implications of Harvesting and Stifling

Cocoon harvesting directly impacts the raw silk yield and market price, with timely collection ensuring higher filament quality and greater economic returns for sericulturists. Cocoon stifling, which involves killing the pupae to prevent moth emergence, adds operational costs but preserves silk integrity, enhancing the value of processed silk threads. Balancing harvesting schedules and stifling methods optimizes resource expenditure while maximizing profitability in sericulture industries.

Environmental Concerns in Cocoon Processing

Cocoon harvesting involves collecting silkworm cocoons without immediate processing, which can minimize chemical use and reduce environmental pollution during initial stages. Cocoon stifling, used to kill pupae inside the cocoons, often relies on heat or chemicals, potentially releasing harmful emissions and affecting air quality. Choosing eco-friendly stifling methods, such as solar or steam, can mitigate environmental impacts while ensuring efficient silk extraction.

Future Trends in Cocoon Harvesting and Stifling Methods

Future trends in cocoon harvesting emphasize mechanized and automated systems to enhance efficiency and reduce labor costs, integrating AI-driven sensors for optimal timing to maximize silk quality. Innovations in cocoon stifling involve eco-friendly and low-energy methods such as solar and microwave technologies, which minimize environmental impact while maintaining fiber integrity. Advances in IoT and data analytics enable real-time monitoring and precision control during both harvesting and stifling, promoting sustainable and high-yield sericulture practices.

Related Important Terms

Green Cocoon Harvesting

Green cocoon harvesting involves collecting cocoons before the silkworm pupae transform, preserving the raw silk's natural luster and strength by preventing pupal death through stifling. This method enhances silk quality by maintaining high protein integrity and reducing defects during cocoon processing compared to traditional cocoon stifling techniques.

On-farm Cocoon Stifling

On-farm cocoon stifling involves controlled heating to kill pupae immediately after harvesting, enhancing silk filament quality and minimizing post-harvest damage. This process ensures uniform moisture levels and prevents spoilage, resulting in improved reelability and higher-grade silk production compared to traditional cocoon harvesting methods.

Solar Cocoon Drying

Cocoon harvesting involves collecting silkworm cocoons promptly at optimal maturity to ensure high-quality silk, while cocoon stifling traditionally uses heat to kill pupae and preserve silk fibers, often impacting fiber luster and strength. Solar cocoon drying utilizes solar energy for stifling, offering an eco-friendly, cost-effective method that maintains silk quality by reducing moisture content without degrading filament strength or color.

Microbial-free Stifling

Cocoon harvesting requires precise timing to ensure optimal silk quality, whereas microbial-free stifling utilizes controlled heat treatment to eliminate bacteria and fungi, enhancing silk fiber hygiene and durability. Employing microbial-free stifling reduces contamination risks, leading to higher-grade silk and improved efficiency in cocoon processing.

Automated Cocoon Sortation

Automated cocoon sortation enhances cocoon processing efficiency by rapidly distinguishing between harvested and stifled cocoons based on quality parameters such as moisture content, weight, and shell integrity. This technology reduces manual labor, minimizes sorting errors, and optimizes raw silk yield by ensuring only high-grade cocoons proceed to reeling.

Humidity-controlled Stifling Chambers

Humidity-controlled stifling chambers enhance cocoon processing by precisely regulating temperature and moisture levels to prevent premature pupal damage during cocoon stifling, ensuring high-quality silk yield. This method outperforms traditional cocoon harvesting by minimizing fiber breakage and improving uniformity, directly impacting silk reelability and commercial value.

Zero-residue Cocoon Harvest

Zero-residue cocoon harvesting in sericulture ensures high-quality silk production by carefully collecting mature cocoons without using chemical treatments, preserving the natural properties of the silk fibers. In contrast, cocoon stifling involves heat or chemical methods to kill pupae, which can leave residues and affect the silk's texture and environmental safety.

Biomass-fired Cocoon Stifling

Biomass-fired cocoon stifling utilizes sustainable organic fuels to efficiently kill pupae and preserve silk fiber quality during cocoon processing, enhancing environmental compatibility compared to traditional harvesting methods. This technique reduces reliance on chemical stifling agents and improves cocoon drying uniformity, resulting in higher silk yield and better filament strength.

Smart Quality Grading (AI-assisted)

Smart Quality Grading using AI-assisted systems enhances cocoon harvesting by accurately assessing cocoon parameters such as weight, color, and firmness in real-time, reducing subjective errors and improving selection precision. This technology also optimizes cocoon stifling processes by predicting optimal temperature and duration, ensuring high-quality silk yield and minimizing post-harvest losses.

Energy-efficient Cocoon Processing

Cocoon harvesting and cocoon stifling are critical steps in sericulture, where energy-efficient cocoon processing techniques significantly reduce electricity and fuel consumption during stifling, preserving silk quality while minimizing environmental impact. Innovations such as solar-powered stifling chambers and optimized thermal management systems enhance energy conservation, supporting sustainable silk production and cost-effective cocoon processing.

Cocoon harvesting vs Cocoon stifling for cocoon processing Infographic

agridif.com

agridif.com