Muga and Eri silks are both integral to indigenous silk production, each offering distinct qualities that cater to different uses. Muga silk is prized for its natural golden sheen, durability, and water resistance, making it ideal for luxury textiles and traditional garments. Eri silk, on the other hand, is valued for its soft texture and thermal insulation properties, often used in cozy, warm clothing and eco-friendly products.

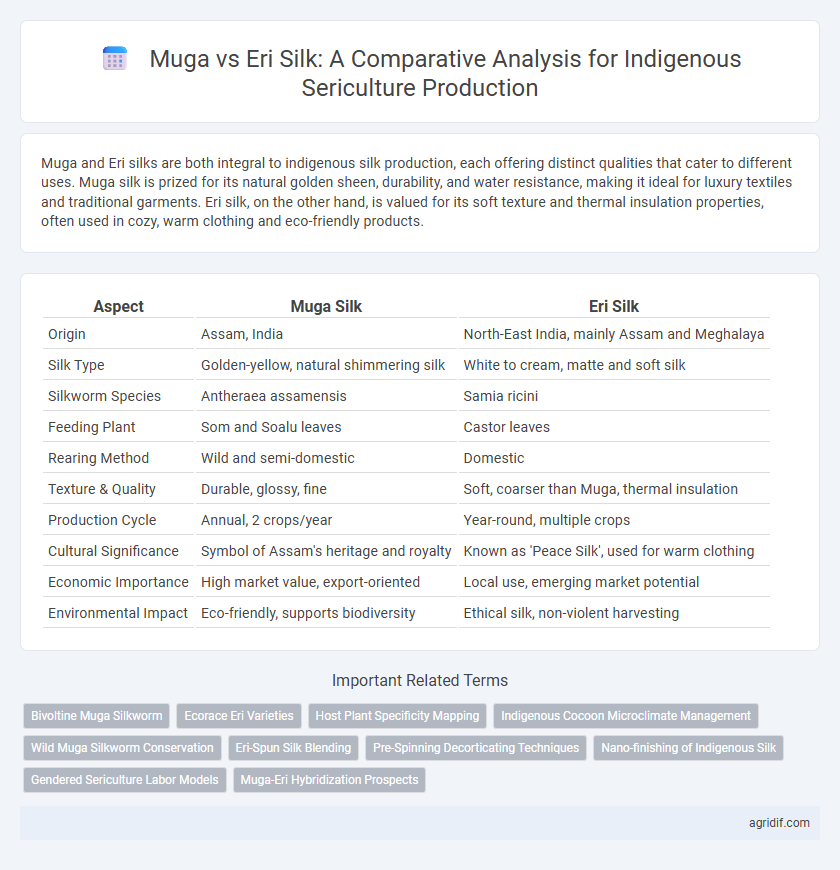

Table of Comparison

| Aspect | Muga Silk | Eri Silk |

|---|---|---|

| Origin | Assam, India | North-East India, mainly Assam and Meghalaya |

| Silk Type | Golden-yellow, natural shimmering silk | White to cream, matte and soft silk |

| Silkworm Species | Antheraea assamensis | Samia ricini |

| Feeding Plant | Som and Soalu leaves | Castor leaves |

| Rearing Method | Wild and semi-domestic | Domestic |

| Texture & Quality | Durable, glossy, fine | Soft, coarser than Muga, thermal insulation |

| Production Cycle | Annual, 2 crops/year | Year-round, multiple crops |

| Cultural Significance | Symbol of Assam's heritage and royalty | Known as 'Peace Silk', used for warm clothing |

| Economic Importance | High market value, export-oriented | Local use, emerging market potential |

| Environmental Impact | Eco-friendly, supports biodiversity | Ethical silk, non-violent harvesting |

Introduction to Muga and Eri Silk in Indigenous Sericulture

Muga and Eri silks are two prominent indigenous silk varieties in sericulture, primarily cultivated in Northeast India. Muga silk, known for its natural golden luster and durability, is produced by the Antheraea assamensis silkworm, while Eri silk, derived from Samia ricini, is valued for its soft texture and thermal properties, making it suitable for diverse climates. These silks support sustainable livelihoods through eco-friendly processes integral to traditional sericulture practices.

Origin and Geographical Distribution of Muga and Eri Silkworms

Muga silkworms (Antheraea assamensis) are indigenous primarily to Assam in Northeast India, thriving in the Brahmaputra valley with a climate suitable for their growth. Eri silkworms (Samia ricini) originate from the eastern regions of India, predominantly found in Assam and parts of Meghalaya, preferring mulberry and castor plants for feeding. The geographical distribution of muga and eri silkworms is closely linked to the specific host plant availability and regional climatic conditions favorable for sustainable indigenous silk production.

Biological Characteristics: Muga vs Eri Silkworms

Muga silkworms (Antheraea assamensis) are bivoltine species known for producing golden-hued, durable silk with high tensile strength, native to Assam and requiring specific host plants like Som and Soalu. Eri silkworms (Samia ricini) are multivoltine, adaptable to a wider range of climatic conditions, and feed primarily on castor and kari leaf, yielding a softer, non-glossy silk ideal for thermal insulation. The biological differences in voltinism, host plant specificity, and silk protein composition significantly influence their suitability for indigenous silk production and product diversification.

Host Plants and Feeding Habits in Muga and Eri Cultivation

Muga silk production relies primarily on the Som (Persea bombycina) and Soalu (Litsea polyantha) host plants, which are indigenous trees found in Assam, providing rich foliage for the Antheraea assamensis larvae. Eri silk cultivation utilizes castor (Ricinus communis) and Kesseru (Heteropanax fragrans) as host plants, enabling Samia ricini larvae to thrive on a diet of castor leaves, which are more widely available and easier to cultivate. Differences in feeding habits influence the quality and texture of silk, with Muga larvae feeding on tougher, aromatic leaves resulting in a lustrous, golden-hued fiber, while Eri larvae produce softer, staple fibers due to a herbaceous diet.

Silk Extraction Processes: Muga vs Eri Techniques

Muga silk extraction involves boiling the cocoons without killing the pupae, preserving the natural golden hue and enhancing fiber strength, while Eri silk extraction employs a non-violent spinning technique where moths emerge before fiber collection, resulting in a woolier texture. Muga processing requires meticulous boiling and reeling methods to maintain filament integrity, whereas Eri silk is spun from shorter fibers, demanding specialized hand-spinning techniques for yarn production. These distinct extraction processes influence the silk's texture, durability, and ecological sustainability, reflecting indigenous practices rooted in regional biodiversity.

Comparative Analysis of Fiber Quality: Muga vs Eri Silk

Muga silk, renowned for its natural golden luster and superior tensile strength, offers a more durable and glossy fiber compared to Eri silk, which is prized for its softness, warmth, and hypoallergenic properties. The tensile strength of Muga silk ranges between 400 to 600 MPa, making it ideal for high-quality textile applications, whereas Eri silk, with lower tensile strength around 200 to 300 MPa, excels in comfort-oriented products such as shawls and blankets. Both fibers are eco-friendly and biodegradable, but Muga's natural sheen and robustness provide a distinct advantage in luxury indigenous silk production.

Economic Significance for Indigenous Communities

Muga silk, native to Assam, commands higher market prices due to its natural golden hue and durability, boosting income for indigenous weavers. Eri silk, often called the "ahimsa silk," offers a sustainable and ethical alternative, supporting community livelihoods through eco-friendly practices. Both silks provide vital economic significance by preserving traditional skills and enabling indigenous communities to access niche markets.

Sustainability and Environmental Impact of Muga and Eri Sericulture

Muga and Eri sericulture both contribute to sustainable indigenous silk production, but Muga silk is prized for its natural golden sheen and eco-friendly rearing process that relies on indigenous host plants like Som and Sualu, promoting biodiversity. Eri silk production, known for its non-violent silk harvesting from the eri silkworm, supports sustainable livelihoods and reduces environmental degradation through agroforestry integration. Both sericulture types employ minimal chemical inputs and foster conservation of local flora, making them vital components of environmentally responsible silk industries in Northeast India.

Challenges Faced by Indigenous Farmers in Muga and Eri Production

Indigenous farmers cultivating Muga and Eri silk face significant challenges including climate sensitivity, requiring specific temperature and humidity levels for optimal yield. Pest infestations and diseases further threaten both silk varieties, while limited access to advanced rearing techniques restricts productivity improvements. Market fluctuations and inadequate infrastructure complicate the sustainability of Muga and Eri sericulture in traditional farming communities.

Future Prospects and Innovations in Indigenous Muga and Eri Silk Industry

Innovations in the indigenous Muga and Eri silk industry focus on sustainable sericulture practices and genetic improvement of silkworm breeds to enhance yield and fiber quality. Future prospects include integrating advanced biotechnology and eco-friendly processing techniques to meet increasing global demand for natural, high-value silk products. Strengthening value chains through community-based enterprises and technology adoption can drive economic growth while preserving traditional knowledge distinct to Assam's silk heritage.

Related Important Terms

Bivoltine Muga Silkworm

Bivoltine Muga silkworms produce high-quality indigenous silk characterized by its natural golden hue, superior durability, and unique texture, distinguishing it from Eri silk which is typically softer and has a creamy white color. The bivoltine nature of Muga silkworms allows for two breeding cycles annually, enhancing indigenous silk production efficiency compared to the univoltine or multivoltine Eri silkworm.

Ecorace Eri Varieties

Ecorace Eri varieties demonstrate superior adaptability and resilience in indigenous sericulture compared to Muga, thriving in diverse agro-climatic conditions and yielding high-quality silk with excellent thermal insulation properties. Their eco-friendly cultivation and continuous silk harvesting cycle make Ecorace Eri an optimal choice for sustainable silk production in Northeastern India.

Host Plant Specificity Mapping

Muga silk production relies primarily on the host plant Som (Machilus bombycina), which thrives in specific agro-climatic zones of Assam, whereas Eri silk depends on Castor (Ricinus communis) and Kesseru (Heteropanax fragrans), enabling broader ecological adaptability. Host plant specificity mapping reveals Muga's narrow, high-altitude niche contrasted with Eri's wider distribution, influencing sustainable indigenous silk cultivation strategies.

Indigenous Cocoon Microclimate Management

Muga silk production requires precise microclimate management with higher humidity and stable temperatures to maintain the delicate golden-yellow cocoons, while Eri silk thrives in comparatively cooler and less humid environments, demanding adaptive cocoon rearing techniques to ensure optimal filament quality. Indigenous sericulture practices emphasize tailored microhabitat control, leveraging local climatic knowledge to enhance cocoon viability and silk yield specific to the Muga and Eri species.

Wild Muga Silkworm Conservation

Muga silk, derived from the wild Antheraea assamensis silkworm native to Assam, offers a unique golden sheen highly prized in indigenous silk production, whereas Eri silk, produced by domesticated Samia ricini, is favored for its soft texture and sustainable farming. Conservation efforts for wild Muga silkworms emphasize habitat protection and biodiversity maintenance to ensure the survival of this culturally significant species amid increasing environmental threats.

Eri-Spun Silk Blending

Eri-spun silk blending enhances the texture and durability of indigenous silk production by combining the resilient, wool-like fibers of eri silk with the lustrous qualities of muga silk, resulting in versatile textiles favored in traditional and contemporary fashion. This blend improves thermal insulation and dye absorption, making it ideal for sustainable, eco-friendly fabric innovation within sericulture-based industries.

Pre-Spinning Decorticating Techniques

Muga silk, prized for its natural golden sheen, requires careful pre-spinning decorticating techniques such as hand-stripping and gentle retting to preserve fiber luster, while Eri silk involves more extensive retting and mechanical decorticating to extract its coarser, staple fibers suitable for weaving. The choice of decorticating method significantly impacts fiber quality, tensile strength, and dye absorption in indigenous silk production, making technique optimization crucial for Muga and Eri sericulture.

Nano-finishing of Indigenous Silk

Nano-finishing of indigenous Muga and Eri silk enhances fiber strength, luster, and dye affinity, preserving their unique texture and thermal properties critical for high-value textile applications. Advanced nano-coating techniques improve Muga's natural golden hue and Eri's durability, optimizing these silks for sustainable fashion with improved resistance to wear and environmental damage.

Gendered Sericulture Labor Models

Muga and Eri silk production in indigenous sericulture exhibit distinct gendered labor models, with women primarily engaged in the delicate rearing and processing of Muga silkworms while men often handle the more physically demanding tasks in Eri cultivation. These gender-specific roles not only reflect cultural traditions but significantly influence the efficiency and economic outcomes of silk production in Northeastern India.

Muga-Eri Hybridization Prospects

Muga-Eri hybridization in sericulture presents promising prospects for enhancing indigenous silk production by combining the superior lustrous quality of Muga silk with the high yield and disease resistance of Eri silk. This hybridization can lead to improved fiber strength, increased production efficiency, and sustainable livelihood opportunities for sericulture farmers predominantly in Northeast India.

Muga vs Eri for Indigenous Silk Production Infographic

agridif.com

agridif.com