Open field rearing of silkworms involves raising larvae on mulberry trees exposed to natural weather conditions, which can result in variability due to pests, diseases, and climate factors. Controlled environment rearing offers precise regulation of temperature, humidity, and light, leading to higher consistency in silkworm growth and silk quality. This method reduces mortality rates and optimizes cocoon production, making it ideal for large-scale sericulture operations aiming for efficiency and quality.

Table of Comparison

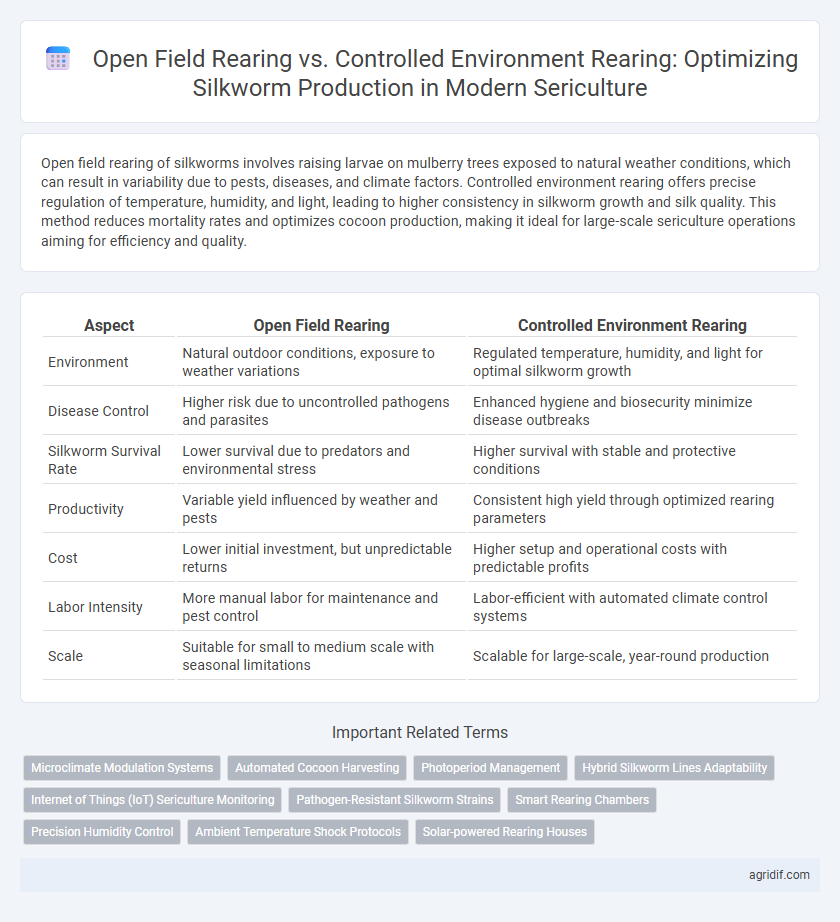

| Aspect | Open Field Rearing | Controlled Environment Rearing |

|---|---|---|

| Environment | Natural outdoor conditions, exposure to weather variations | Regulated temperature, humidity, and light for optimal silkworm growth |

| Disease Control | Higher risk due to uncontrolled pathogens and parasites | Enhanced hygiene and biosecurity minimize disease outbreaks |

| Silkworm Survival Rate | Lower survival due to predators and environmental stress | Higher survival with stable and protective conditions |

| Productivity | Variable yield influenced by weather and pests | Consistent high yield through optimized rearing parameters |

| Cost | Lower initial investment, but unpredictable returns | Higher setup and operational costs with predictable profits |

| Labor Intensity | More manual labor for maintenance and pest control | Labor-efficient with automated climate control systems |

| Scale | Suitable for small to medium scale with seasonal limitations | Scalable for large-scale, year-round production |

Introduction to Silkworm Rearing Methods

Open field rearing of silkworms involves cultivating mulberry leaves in natural environmental conditions, exposing larvae to variable weather, pests, and diseases, which can affect yield stability. Controlled environment rearing employs regulated temperature, humidity, and light in facilities to optimize silkworm growth, enhancing cocoon quality and production consistency. Comparing these methods highlights trade-offs between cost-effectiveness and production control essential for sustainable sericulture development.

Overview of Open Field Rearing

Open field rearing for silkworm production involves cultivating silkworms in natural outdoor environments, relying on ambient temperature, humidity, and ventilation. This method is cost-effective and harnesses natural resources but often faces challenges such as unpredictable weather conditions, pest infestations, and disease outbreaks that impact yield consistency. Open field rearing remains popular in traditional sericulture regions due to its simplicity and lower initial investment requirements.

Advantages of Open Field Rearing

Open field rearing of silkworms offers cost-effectiveness due to minimal infrastructure requirements and utilizes natural environmental conditions, reducing energy consumption. Exposure to natural sunlight and ventilation promotes better cocoon quality and robust larval development. It also allows easier disease control through open airflow and reduced humidity, minimizing the risk of fungal infections.

Challenges in Open Field Silkworm Rearing

Open field rearing of silkworms faces significant challenges including vulnerability to unpredictable weather conditions, pest infestations, and diseases, which often result in inconsistent silk yield and quality. Lack of controlled temperature and humidity leads to suboptimal larval growth and increases mortality rates. Additionally, environmental pollutants and bird predation further reduce productivity compared to controlled environment rearing systems.

Controlled Environment Rearing: Key Features

Controlled environment rearing for silkworm production utilizes precise regulation of temperature, humidity, and light to optimize larval growth and cocoon quality. This method minimizes disease outbreaks and enhances yield consistency by maintaining sterile conditions and reducing external environmental stressors. Advanced climate control systems and automated feeding techniques are integral to maximizing productivity and ensuring uniform silk fiber characteristics.

Benefits of Controlled Environment Rearing

Controlled environment rearing for silkworm production enhances larvae survival rates by maintaining optimal temperature, humidity, and light conditions, leading to consistent cocoon quality. This method reduces disease outbreaks through improved sanitation and controlled airflow, minimizing economic losses. Precision environmental control accelerates growth cycles and increases yield, making it a preferred choice for large-scale sericulture operations.

Drawbacks of Controlled Environment Rearing

Controlled environment rearing for silkworm production incurs high energy costs due to the need for precise management of temperature, humidity, and ventilation. The initial investment and maintenance of specialized infrastructure such as climate-controlled rooms and automated systems can be prohibitively expensive for small-scale sericulture farmers. Moreover, the risk of system failures or power outages may lead to significant losses in silkworm batches, undermining production reliability.

Comparative Analysis: Yield and Quality

Open field rearing of silkworms often results in variable yield and inconsistent cocoon quality due to exposure to environmental fluctuations and pests. Controlled environment rearing enables precise regulation of temperature, humidity, and light, leading to higher cocoon uniformity and improved silk filament quality. Studies indicate that controlled environment systems can increase yield by up to 20% and enhance fiber tensile strength by maintaining optimal conditions throughout the silkworm lifecycle.

Economic Considerations in Rearing Methods

Open field rearing of silkworms incurs lower initial investment due to minimal infrastructure requirements but faces higher risks from environmental factors causing potential crop losses. Controlled environment rearing demands significant capital expenditure for climate regulation equipment, increasing operational costs but enhances cocoon yield stability and quality through optimized temperature and humidity. Economic efficiency depends on balancing investment costs with output reliability, where controlled systems often yield higher profit margins despite elevated expenses.

Future Trends in Silkworm Rearing Practices

Future trends in silkworm rearing emphasize a shift from traditional open field methods toward controlled environment systems that enhance productivity through precise regulation of temperature, humidity, and light. Controlled environment rearing minimizes disease risk and allows for year-round production, supporting higher yields and improved silk quality. Advances in biotechnology and automation further optimize larval growth and cocooning efficiency, promoting sustainable and scalable sericulture practices.

Related Important Terms

Microclimate Modulation Systems

Open field rearing of silkworms exposes larvae to variable weather conditions, impacting growth rates and cocoon quality, whereas controlled environment rearing employs microclimate modulation systems such as humidity and temperature controls to optimize silkworm health and maximize yield consistency. Advanced climate control technologies, including automated ventilation and misting systems, create stable conditions that enhance larval development, reduce disease incidence, and improve overall silk productivity.

Automated Cocoon Harvesting

Automated cocoon harvesting in controlled environment rearing enhances efficiency by maintaining optimal temperature, humidity, and light conditions, reducing labor costs and minimizing silk waste compared to traditional open field methods. This technology improves silkworm health and cocoon quality through precise environmental control, facilitating higher yield and consistent production cycles.

Photoperiod Management

Open field rearing of silkworms exposes larvae to natural photoperiod fluctuations, resulting in variable growth rates and sporadic silk yield, while controlled environment rearing allows precise photoperiod management to synchronize larval development and optimize cocoon quality. Implementing artificial lighting regimes in controlled environments enhances silkworm metabolic activity and accelerates silk protein synthesis, leading to higher productivity and improved sericulture efficiency.

Hybrid Silkworm Lines Adaptability

Hybrid silkworm lines exhibit greater adaptability in controlled environment rearing, where temperature, humidity, and light conditions are optimized for enhanced cocoon yield and quality. Open field rearing exposes hybrids to variable climatic stresses, often resulting in lower productivity and increased vulnerability to pests and diseases.

Internet of Things (IoT) Sericulture Monitoring

Open field rearing of silkworms exposes larvae to environmental variability and increased disease risk, limiting yield consistency, while controlled environment rearing leverages IoT sericulture monitoring systems to optimize temperature, humidity, and ventilation in real-time, enhancing larval growth and cocoon quality. IoT-integrated sensors and data analytics enable precise control over microclimate conditions, improving silkworm health and boosting productivity compared to traditional open field methods.

Pathogen-Resistant Silkworm Strains

Pathogen-resistant silkworm strains exhibit higher survival rates and enhanced cocoon quality when reared in controlled environments, minimizing exposure to environmental pathogens common in open field rearing. Controlled environment rearing optimizes temperature, humidity, and hygiene, significantly reducing disease outbreaks and ensuring consistent silk yield compared to the variable conditions of open field methods.

Smart Rearing Chambers

Open field rearing exposes silkworms to fluctuating weather conditions, increasing risks of disease and predation, while controlled environment rearing in Smart Rearing Chambers ensures optimal temperature, humidity, and ventilation, significantly enhancing cocoon yield and silk quality. Advanced sensor technology and automated controls in these chambers facilitate precise monitoring and adjustments, reducing labor costs and improving overall sericulture productivity.

Precision Humidity Control

Open field rearing in sericulture relies on natural humidity fluctuations, often resulting in inconsistent silkworm growth and increased disease risk, while controlled environment rearing utilizes precision humidity control systems to maintain optimal moisture levels that enhance larval development and maximize cocoon quality. Precision humidity control in indoor setups enables stable microclimates, significantly improving yield uniformity and reducing mortality compared to open field methods.

Ambient Temperature Shock Protocols

Open field rearing of silkworms exposes larvae to fluctuating ambient temperatures, requiring robust temperature shock protocols to enhance stress tolerance and sustain cocoon yield. Controlled environment rearing allows precise regulation of temperature and humidity, enabling optimized thermal shock treatments that improve silkworm survival rates and silk quality.

Solar-powered Rearing Houses

Open field rearing for silkworms exposes larvae to fluctuating weather conditions, increasing mortality rates and reducing cocoon quality, whereas controlled environment rearing in solar-powered rearing houses ensures stable temperature and humidity, optimizing silkworm growth and silk yield. Solar energy utilization in these rearing houses not only reduces operational costs but also promotes sustainable and eco-friendly sericulture practices.

Open field rearing vs Controlled environment rearing for silkworm production Infographic

agridif.com

agridif.com