Belt conveyors offer higher capacity and smoother grain handling with minimal damage, making them ideal for long-distance transport in agricultural engineering. Screw conveyors, while compact and effective for short distances or elevation changes, tend to cause more grain degradation due to their mechanical action. Selecting the appropriate conveyor depends on factors like grain type, distance, and the need to maintain grain integrity during handling.

Table of Comparison

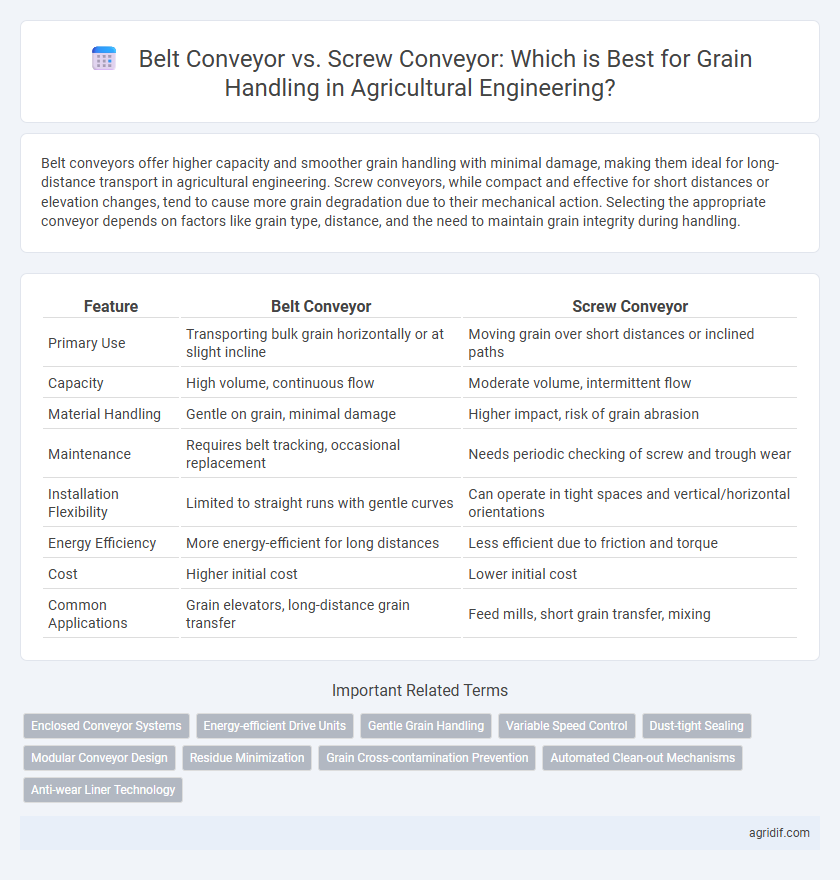

| Feature | Belt Conveyor | Screw Conveyor |

|---|---|---|

| Primary Use | Transporting bulk grain horizontally or at slight incline | Moving grain over short distances or inclined paths |

| Capacity | High volume, continuous flow | Moderate volume, intermittent flow |

| Material Handling | Gentle on grain, minimal damage | Higher impact, risk of grain abrasion |

| Maintenance | Requires belt tracking, occasional replacement | Needs periodic checking of screw and trough wear |

| Installation Flexibility | Limited to straight runs with gentle curves | Can operate in tight spaces and vertical/horizontal orientations |

| Energy Efficiency | More energy-efficient for long distances | Less efficient due to friction and torque |

| Cost | Higher initial cost | Lower initial cost |

| Common Applications | Grain elevators, long-distance grain transfer | Feed mills, short grain transfer, mixing |

Introduction to Grain Handling Systems

Grain handling systems utilize belt conveyors and screw conveyors to optimize the movement and storage of harvested crops. Belt conveyors offer high-capacity, gentle transport ideal for long distances and bulk grain flow, while screw conveyors excel in controlled, metered feeding and short-distance material transfer. Selecting the appropriate conveyor type depends on factors like grain type, moisture content, and facility layout to ensure efficient and damage-free handling.

Overview of Belt Conveyors in Agriculture

Belt conveyors in agriculture offer efficient, continuous transport of grain with minimal damage and high throughput capacity, making them ideal for bulk material handling. Their flexible design accommodates long distances and elevation changes, optimizing grain flow during harvesting, storage, and processing. Durable materials and low maintenance requirements ensure reliable performance in harsh agricultural environments, enhancing operational efficiency and reducing downtime.

Overview of Screw Conveyors in Agriculture

Screw conveyors are widely used in agriculture for efficient grain handling, offering compact design and reliable performance in moving bulk materials like grains. Their helical screw blade rotates within a trough, ensuring consistent feed rates and minimal grain damage during transport. These conveyors excel in applications requiring precise control over grain flow and versatility in handling varying moisture content and particle sizes.

Key Differences: Belt Conveyor vs Screw Conveyor

Belt conveyors offer higher capacity and faster grain transport over long distances with minimal grain damage, making them ideal for bulk handling in large-scale agricultural operations. Screw conveyors provide precise metering and are better suited for short distances and confined spaces, though they can cause more grain abrasion due to their rotating screw mechanism. The choice between belt and screw conveyors depends largely on factors such as grain type, distance, capacity requirements, and space constraints in grain handling systems.

Efficiency and Throughput Comparison

Belt conveyors offer higher throughput rates and greater efficiency for grain handling due to their continuous, smooth transport and ability to handle larger volumes with minimal grain damage. Screw conveyors are suitable for shorter distances and lower capacities but tend to have lower energy efficiency and increased grain breakage caused by the rotating screw mechanism. For large-scale agricultural operations, belt conveyors outperform screw conveyors in maintaining grain quality while maximizing throughput and reducing operational costs.

Maintenance and Durability Considerations

Belt conveyors offer lower maintenance due to fewer moving parts and are generally more durable under continuous, heavy grain loads, minimizing downtime in agricultural operations. Screw conveyors require frequent inspection of the spiral and trough for wear and potential grain damage, which can increase maintenance costs and reduce overall lifespan. Material build-up and abrasion in screw conveyors accelerate wear, whereas belt conveyors with proper tensioning and alignment maintain efficiency and extend service intervals.

Energy Consumption Analysis

Belt conveyors typically exhibit lower energy consumption per ton of grain transported compared to screw conveyors, due to reduced friction and smoother operation. Energy efficiency in belt conveyors is enhanced by their ability to move larger volumes at higher speeds with less mechanical resistance. In contrast, screw conveyors involve higher power usage caused by the rotational movement of the helical blade directly in contact with grain, leading to increased energy costs in grain handling applications.

Suitability for Different Grain Types

Belt conveyors provide gentle handling and minimal grain damage, making them ideal for fragile grains like corn and soybeans, while screw conveyors are better suited for dense, coarse grains such as wheat and barley due to their robust design. Belt conveyors excel in long-distance transport and high-volume throughput, whereas screw conveyors are more efficient for short-haul, controlled feed rates and can handle grain with higher moisture content. Choosing the appropriate conveyor depends on factors like grain type, moisture level, and transport distance, ensuring optimal performance and grain quality preservation.

Cost Implications and Economic Analysis

Belt conveyors generally offer lower maintenance costs and higher energy efficiency compared to screw conveyors, making them economically favorable for long-distance grain handling. Screw conveyors require more frequent maintenance due to increased wear and higher power consumption, which can escalate operational expenses over time. Initial investment for screw conveyors is typically lower, but the total cost of ownership is often higher when factoring in durability and maintenance in grain handling applications.

Choosing the Right Conveyor for Grain Handling

Belt conveyors provide smooth, gentle handling ideal for large volumes of grain, minimizing damage and spillage during transport over long distances. Screw conveyors excel in controlled feeding and precise metering but may cause more grain degradation and are better suited for shorter, enclosed material transfer. Selecting between belt and screw conveyors requires evaluating factors such as grain type, capacity, transfer distance, and the need for grain integrity preservation.

Related Important Terms

Enclosed Conveyor Systems

Enclosed belt conveyor systems offer efficient grain handling with minimal spillage and dust emission, making them ideal for maintaining grain quality during transport. Screw conveyors, while compact and suitable for controlled discharge, often generate more grain abrasion and heat, reducing their effectiveness for delicate or bulk grain transport in enclosed setups.

Energy-efficient Drive Units

Belt conveyors for grain handling typically feature energy-efficient variable frequency drives (VFDs) that optimize motor speed and reduce power consumption during operation. In contrast, screw conveyors often employ constant-speed motors that may lead to higher energy use, although recent advances in modular, high-efficiency drive units are closing this gap.

Gentle Grain Handling

Belt conveyors provide gentle grain handling by minimizing grain impact and abrasion during transport, preserving kernel integrity and reducing breakage compared to screw conveyors. Screw conveyors often cause higher grain damage due to their rotating flights, which can lead to kernel crushing and increased fines generation in grain handling operations.

Variable Speed Control

Variable speed control in belt conveyors allows precise adjustment of material flow rates, enhancing efficiency in grain handling by minimizing spillage and reducing mechanical wear. Screw conveyors with variable speed drives provide consistent grain movement and improved control in confined spaces, making them ideal for precise dosing and delicate handling in agricultural operations.

Dust-tight Sealing

Belt conveyors offer superior dust-tight sealing for grain handling due to their enclosed design and continuous belt surface that minimizes grain spillage and airborne dust. Screw conveyors, while effective for bulk movement, often require additional sealing measures to prevent dust leakage, making belt conveyors the preferred choice for maintaining clean and safe grain processing environments.

Modular Conveyor Design

Modular conveyor design in agricultural engineering enhances adaptability and maintenance efficiency, with belt conveyors offering superior grain handling capacity and gentle material transport, while screw conveyors provide compactness and efficient handling of granular materials in confined spaces. Optimizing conveyor choice depends on specific farm requirements, material characteristics, and scalability needs, ensuring efficient grain flow and minimizing mechanical wear.

Residue Minimization

Belt conveyors offer superior residue minimization for grain handling by providing a continuous, smooth surface that reduces grain spillage and dust generation compared to screw conveyors. Screw conveyors tend to trap grain particles in the helical flights, leading to higher residue accumulation and increased cleaning frequency in agricultural processing facilities.

Grain Cross-contamination Prevention

Belt conveyors reduce grain cross-contamination by providing a continuous, enclosed surface that minimizes residue buildup and easy cleaning compared to screw conveyors, which have multiple contact points and potential grain entrapment areas. Screw conveyors may harbor residual grain and moisture in the screw flights, increasing contamination risks and requiring more intensive maintenance protocols to ensure hygienic operation in grain handling.

Automated Clean-out Mechanisms

Automated clean-out mechanisms in belt conveyors for grain handling utilize sensors and adjustable scrapers to minimize grain spillage and reduce downtime during residue removal, enhancing operational efficiency. In contrast, screw conveyors employ automated rotary brushes and purge systems designed to clear residual grain from the helical flights, preventing contamination and maintaining continuous flow in automated agricultural processes.

Anti-wear Liner Technology

Belt conveyors equipped with advanced anti-wear liner technology offer superior durability and reduced maintenance in grain handling by minimizing abrasion and material spillage compared to screw conveyors. Screw conveyors, while effective in confined spaces, often require frequent liner replacements due to higher friction and wear, making belt conveyors a more cost-efficient solution for large-scale agricultural operations.

Belt Conveyor vs Screw Conveyor for Grain Handling Infographic

agridif.com

agridif.com