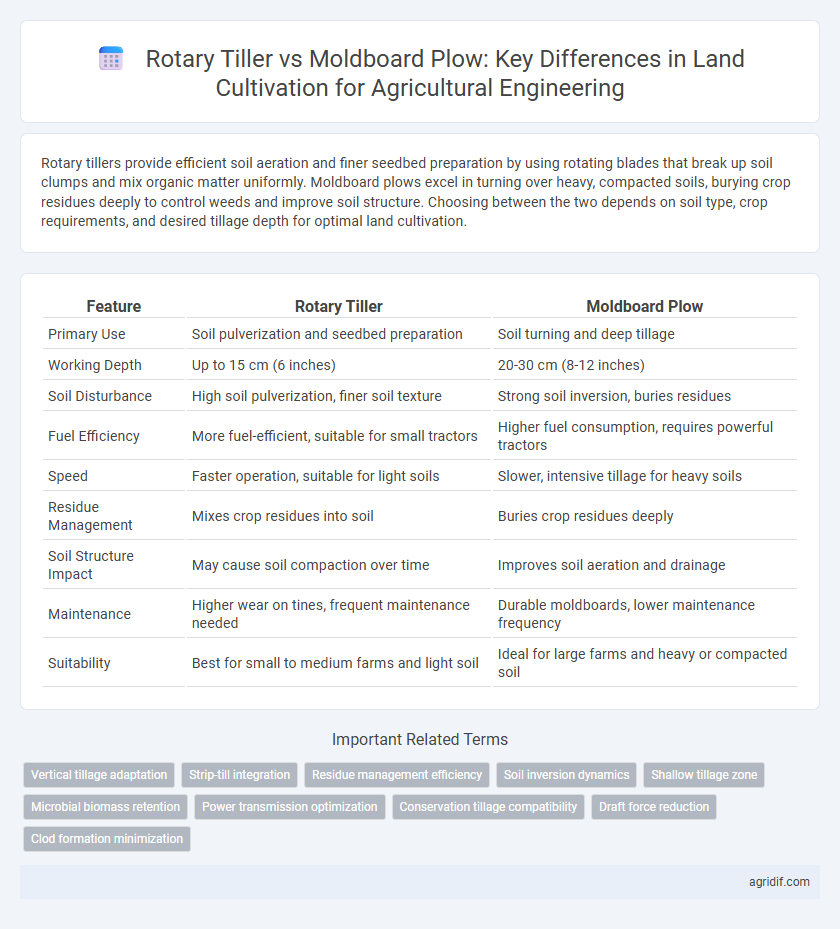

Rotary tillers provide efficient soil aeration and finer seedbed preparation by using rotating blades that break up soil clumps and mix organic matter uniformly. Moldboard plows excel in turning over heavy, compacted soils, burying crop residues deeply to control weeds and improve soil structure. Choosing between the two depends on soil type, crop requirements, and desired tillage depth for optimal land cultivation.

Table of Comparison

| Feature | Rotary Tiller | Moldboard Plow |

|---|---|---|

| Primary Use | Soil pulverization and seedbed preparation | Soil turning and deep tillage |

| Working Depth | Up to 15 cm (6 inches) | 20-30 cm (8-12 inches) |

| Soil Disturbance | High soil pulverization, finer soil texture | Strong soil inversion, buries residues |

| Fuel Efficiency | More fuel-efficient, suitable for small tractors | Higher fuel consumption, requires powerful tractors |

| Speed | Faster operation, suitable for light soils | Slower, intensive tillage for heavy soils |

| Residue Management | Mixes crop residues into soil | Buries crop residues deeply |

| Soil Structure Impact | May cause soil compaction over time | Improves soil aeration and drainage |

| Maintenance | Higher wear on tines, frequent maintenance needed | Durable moldboards, lower maintenance frequency |

| Suitability | Best for small to medium farms and light soil | Ideal for large farms and heavy or compacted soil |

Introduction to Land Cultivation Techniques

Rotary tillers and moldboard plows serve distinct roles in land cultivation, with rotary tillers using rotating blades to break soil into fine particles, ideal for seedbed preparation and weed control. Moldboard plows turn over the soil in large furrows, effectively burying crop residues and aerating the ground, which promotes deeper root growth and improved soil structure. Choosing between these techniques depends on soil type, crop requirements, and the desired level of soil disturbance for optimal agronomic results.

Overview of Rotary Tiller and Moldboard Plow

Rotary tillers utilize rotating blades to break up soil, offering efficient mixing of organic matter and weed control for seedbed preparation, ideal for small to medium farms. Moldboard plows cut and invert soil slices, effectively burying crop residues and aerating heavy soils but may cause soil erosion if used improperly. Both tools cater to different cultivation needs, with rotary tillers favored for precision tillage and moldboard plows suited for deep soil turning in large-scale farming.

Working Principles: How Each Implement Functions

Rotary tillers operate using rotating blades that churn and break up soil for fine seedbed preparation, effectively mixing organic matter and soil. Moldboard plows function by slicing through the soil with a curved moldboard that inverts soil layers, burying crop residues and aerating the land. The rotary tiller's mechanical action suits shallow cultivation and weed control, whereas the moldboard plow is ideal for deep tillage and soil turning.

Suitability for Different Soil Types

Rotary tillers excel in sandy and loamy soils by providing fine soil pulverization and better seedbed preparation, making them ideal for light to medium soil textures. Moldboard plows are more suitable for heavy clay and compacted soils, effectively inverting and breaking up dense layers to improve aeration and drainage. Choosing between the two depends on soil structure, with rotary tillers preferred for softer soils and moldboard plows for challenging, high-resistance terrains.

Impact on Soil Structure and Health

Rotary tillers break up soil with rotating blades, promoting aeration and rapid seedbed preparation but can lead to soil compaction and disruption of microbial habitats. Moldboard plows invert soil deeply, burying crop residues and controlling weeds while potentially causing increased erosion and loss of organic matter on the surface. Balancing these tools depends on soil type and conservation goals to maintain long-term soil structure and health.

Efficiency and Speed of Land Preparation

Rotary tillers offer high efficiency in land preparation by rapidly breaking up soil with rotating blades, enabling faster seedbed formation compared to traditional moldboard plows. Moldboard plows excel in deep soil inversion but operate at slower speeds due to their reliance on tractor power and their design, which cuts and flips soil rather than pulverizing it. For large-scale agriculture requiring quick turnaround, rotary tillers enhance productivity by reducing cultivation time by up to 50% in suitable soil conditions.

Fuel Consumption and Operational Costs

Rotary tillers generally consume more fuel due to their higher engine power requirements compared to moldboard plows, impacting overall operational costs in land cultivation. Moldboard plows, while slower, offer lower fuel consumption and reduced maintenance expenses, making them cost-effective for large-scale farming. Choosing between the two tools depends on balancing fuel efficiency with soil preparation needs and total expenditure.

Maintenance Requirements and Durability

Rotary tillers require regular inspection and timely replacement of blades to maintain optimal performance, whereas moldboard plows demand periodic sharpening and robust frame checks due to their heavy-duty use. The durability of moldboard plows generally surpasses rotary tillers as they are constructed with thicker steel and designed for extensive soil turnover, making them suitable for tough, rocky soils. Maintenance costs tend to be lower for moldboard plows over time, given their simpler mechanical design compared to the complex moving parts of rotary tillers.

Crop Productivity and Yield Implications

Rotary tillers enhance soil aeration and seedbed preparation, promoting uniform nutrient distribution and improved root penetration, which significantly boosts crop productivity. Moldboard plows are effective in turning over soil to control weeds and incorporate residues but may lead to soil compaction and moisture loss, potentially reducing yield over time. Choosing rotary tillers often results in higher yields due to better soil structure and moisture retention compared to conventional moldboard plowing.

Choosing the Right Implement for Your Farm

Rotary tillers offer efficient soil pulverization and weed control, ideal for small to medium farms with lighter soils, while moldboard plows excel in turning over heavy, compacted soils and incorporating crop residues. Evaluating soil type, farm size, and cultivation goals ensures optimal implement selection, enhancing soil aeration and preparing seedbeds effectively. Balancing fuel efficiency, maintenance needs, and soil conservation practices aligns land preparation techniques with sustainable agricultural productivity.

Related Important Terms

Vertical tillage adaptation

Rotary tillers offer superior vertical tillage adaptation by providing consistent soil pulverization and residue incorporation, enhancing seedbed preparation without excessive soil inversion. Moldboard plows, while effective for deep soil turning, disrupt soil structure more and may hinder vertical tillage benefits by burying organic matter and increasing erosion risks.

Strip-till integration

Rotary tillers offer precise soil pulverization and residue mixing, enhancing nutrient availability but often causing soil structure disruption, while moldboard plows excel in deep soil inversion beneficial for weed control and residue burial, yet may increase erosion risk. Integrating strip-till practices with rotary tillers promotes minimal soil disturbance by cultivating narrow strips, optimizing moisture retention and root penetration, whereas moldboard plow integration in strip-till systems is less common due to its extensive inversion action conflicting with conservation goals.

Residue management efficiency

Rotary tillers excel in residue management by finely chopping crop residues and incorporating them directly into the soil, enhancing decomposition and nutrient cycling. Moldboard plows bury residues beneath the surface, reducing surface residue but potentially increasing soil erosion risk and residue decomposition time.

Soil inversion dynamics

Rotary tillers use rotating blades to break up soil, promoting fine soil particle distribution and partial mixing of residues, while moldboard plows invert the soil completely, burying crop residues and weeds deeper to enhance soil aeration and weed control. The soil inversion dynamics of moldboard plows result in more pronounced disruption of soil layers compared to the surface-level mixing of rotary tillers, influencing nutrient distribution and soil structure differently.

Shallow tillage zone

Rotary tillers create a shallow tillage zone by pulverizing soil to a depth of 4-6 inches, enhancing seedbed preparation and weed control with minimal soil disturbance. In contrast, moldboard plows invert soil layers deeper (8-12 inches), which can disrupt soil structure and increase erosion risk in shallow tillage zones.

Microbial biomass retention

Rotary tillers promote higher microbial biomass retention by minimizing soil disturbance and maintaining organic matter near the surface, enhancing nutrient cycling and soil health. In contrast, moldboard plows invert the soil completely, disrupting microbial habitats and reducing microbial biomass, which can decrease overall soil fertility.

Power transmission optimization

Rotary tillers utilize direct mechanical power transmission through gearboxes and PTO shafts, offering higher efficiency and reduced power loss compared to moldboard plows, which rely on draft force transmitted via tractor linkage systems that often result in greater energy dissipation. Optimizing power transmission in rotary tillers enhances fuel efficiency and soil turnover uniformity, while moldboard plows require precise tractor calibration to minimize mechanical strain and maximize traction effectiveness.

Conservation tillage compatibility

Rotary tillers provide effective soil aeration but can disrupt soil structure and increase erosion, making them less compatible with conservation tillage practices that emphasize minimal soil disturbance. Moldboard plows invert the soil completely, leading to higher erosion risks and lower compatibility with conservation tillage methods aimed at preserving soil integrity and moisture retention.

Draft force reduction

Rotary tillers reduce draft force by utilizing high-speed rotating blades that break soil particles into finer aggregates, decreasing soil resistance compared to the moldboard plow's heavy, deep soil inversion method. This results in lower fuel consumption and reduced tractor power requirements during land cultivation, enhancing overall energy efficiency.

Clod formation minimization

Rotary tillers effectively minimize clod formation by breaking soil into finer particles through rapid, multi-directional blades, enhancing seedbed preparation and promoting uniform soil texture. Moldboard plows, while efficient in turning soil, often result in larger clods due to single-directional soil inversion, which can hinder seedbed uniformity and require additional tillage for clod reduction.

Rotary tiller vs Moldboard plow for land cultivation Infographic

agridif.com

agridif.com