The combine harvester significantly boosts harvesting efficiency by simultaneously cutting, threshing, and cleaning grains, reducing labor and time compared to the reaper-binder. While the reaper-binder cuts and binds crops into sheaves, it requires additional manual effort for threshing, making it less suitable for large-scale operations. Modern farming favors the combine harvester for its ability to handle vast fields swiftly and deliver higher productivity.

Table of Comparison

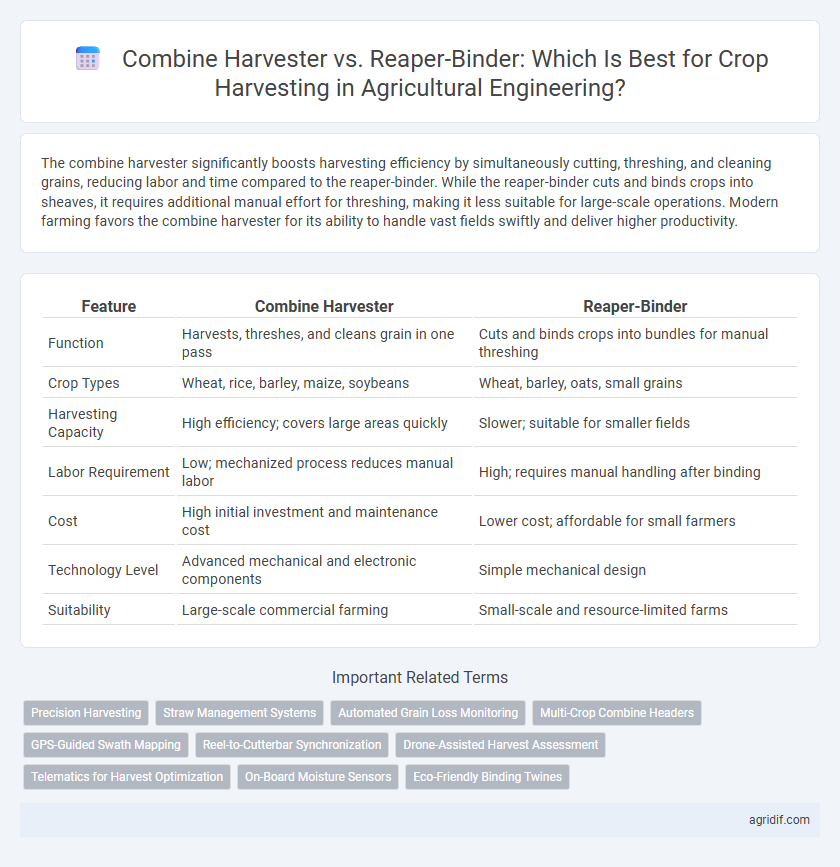

| Feature | Combine Harvester | Reaper-Binder |

|---|---|---|

| Function | Harvests, threshes, and cleans grain in one pass | Cuts and binds crops into bundles for manual threshing |

| Crop Types | Wheat, rice, barley, maize, soybeans | Wheat, barley, oats, small grains |

| Harvesting Capacity | High efficiency; covers large areas quickly | Slower; suitable for smaller fields |

| Labor Requirement | Low; mechanized process reduces manual labor | High; requires manual handling after binding |

| Cost | High initial investment and maintenance cost | Lower cost; affordable for small farmers |

| Technology Level | Advanced mechanical and electronic components | Simple mechanical design |

| Suitability | Large-scale commercial farming | Small-scale and resource-limited farms |

Introduction to Modern Crop Harvesting Technologies

Combine harvesters integrate cutting, threshing, and cleaning operations into a single machine, significantly increasing harvesting efficiency compared to reaper-binders, which primarily cut and bind crops manually. Modern combine harvesters feature advanced sensors and GPS technology to optimize harvesting processes and reduce grain loss, making them ideal for large-scale farming. In contrast, reaper-binders remain suitable for small farms and uneven terrains where mechanized combines may struggle.

Overview of Combine Harvesters

Combine harvesters integrate reaping, threshing, and winnowing into a single operation, significantly boosting harvesting efficiency for cereal crops like wheat, barley, and rice. Equipped with advanced threshing mechanisms and adjustable settings, combine harvesters handle varying crop conditions and moisture levels, reducing grain loss and improving overall yield quality. Modern models also feature GPS and automation technologies, enhancing precision and reducing labor requirements compared to traditional reaper-binders.

Overview of Reaper-Binders

Reaper-binders are agricultural machines designed for cutting and binding crops like wheat, barley, and oats into sheaves, facilitating easier handling and drying before threshing. Unlike combine harvesters, which simultaneously cut, thresh, and clean grain in a single pass, reaper-binders perform only the initial steps of harvesting, making them suitable for smaller farms or areas with uneven terrain. Their simplicity and lower cost compared to combine harvesters make reaper-binders a viable choice where mechanized threshing facilities are available separately.

Key Differences in Harvesting Mechanisms

The combine harvester integrates reaping, threshing, and winnowing operations into a single process, significantly enhancing harvesting efficiency for crops like wheat and barley. The reaper-binder cuts and binds crops into bundles, requiring separate threshing afterward, which is labor-intensive and time-consuming. Combining multiple harvesting stages, the combine harvester reduces crop loss and operational time compared to the traditional reaper-binder mechanism.

Efficiency and Productivity Comparison

Combine harvesters significantly outperform reaper-binders in efficiency and productivity by integrating cutting, threshing, and cleaning processes into a single operation, reducing harvest time by up to 50%. The advanced technology in combine harvesters enables higher grain recovery rates and lowers crop losses compared to reaper-binders, which require additional manual threshing and handling. In large-scale farming, the mechanized design of combine harvesters leads to increased throughput and labor savings, making them the preferred choice for maximizing harvesting efficiency.

Suitability for Different Crop Types

Combine harvesters excel in harvesting cereals like wheat, barley, and oats by simultaneously reaping, threshing, and winnowing, making them suitable for large-scale grain production. Reaper-binders are better suited for crops that require binding into sheaves, such as rice, barley, and small grains in smaller or uneven fields. The choice depends on crop type, field size, and post-harvest handling requirements, with combine harvesters favoring high-efficiency grain processing and reaper-binders offering versatility for bundled crop management.

Cost Analysis and Economic Considerations

Combine harvesters offer higher efficiency and greater versatility compared to reaper-binders, leading to reduced labor costs and faster harvesting cycles, which translates to better crop quality and market value retention. Initial investment and maintenance costs for combine harvesters are significantly higher, but their ability to integrate threshing and cleaning processes reduces post-harvest expenses and time. Reaper-binders have lower upfront costs and are suitable for small-scale farms, but higher labor requirements and slower operation can increase overall harvesting costs, making them less economical for large-scale commercial agriculture.

Maintenance and Operational Requirements

Combine harvesters require advanced maintenance such as regular engine servicing, hydraulic system checks, and blade sharpening to ensure optimal performance during large-scale crop harvesting. Reaper-binders have simpler mechanical components demanding less frequent but consistent upkeep, including string replacement and routine lubrication of moving parts. Operationally, combine harvesters need skilled operators trained in modern controls, while reaper-binders allow for easier handling with basic agricultural knowledge.

Environmental Impact Assessment

Combine harvesters optimize crop harvesting by integrating reaping, threshing, and cleaning processes into a single operation, significantly reducing fuel consumption and soil compaction compared to reaper-binders. Reaper-binders, while effective for small-scale farming, require multiple passes over the field, increasing greenhouse gas emissions and soil disturbance. Environmental impact assessments highlight that combine harvesters offer a more sustainable option with lower carbon footprints and minimized soil erosion risks.

Future Trends in Crop Harvesting Equipment

Future trends in crop harvesting equipment emphasize increased automation and precision technology in combine harvesters, enhancing efficiency and reducing crop loss. Reaper-binders may evolve with improved cutting mechanics and integration of GPS for better field navigation but are expected to be largely supplanted by multifunctional combine harvesters. Advanced sensor systems, AI-driven yield monitoring, and machine learning algorithms will drive the next generation of harvesting machinery in agricultural engineering.

Related Important Terms

Precision Harvesting

Combine harvesters utilize advanced sensor technology and GPS-guided systems to achieve high-precision harvesting by simultaneously performing reaping, threshing, and winnowing, significantly reducing crop losses and improving yield accuracy. Reaper-binders, while effective for cutting and binding crops, lack the integrated automation and real-time data analytics essential for precision harvesting, making them less efficient for large-scale, precise crop management.

Straw Management Systems

Combine harvesters feature integrated straw choppers and spreaders that efficiently manage crop residue by chopping and evenly distributing straw across the field, promoting faster decomposition and soil health. In contrast, reaper-binders cut and bundle straw, requiring additional manual or mechanical handling for straw management, which can limit operational efficiency and delay field clearance.

Automated Grain Loss Monitoring

Combine harvesters integrate advanced automated grain loss monitoring systems using optical sensors and load cells to maximize harvesting efficiency and minimize waste, outperforming reaper-binders that lack real-time data feedback. These automated systems enable precise adjustments during harvesting, ensuring optimal grain retention and reducing crop losses significantly compared to traditional manual monitoring methods in reaper-binders.

Multi-Crop Combine Headers

Multi-crop combine headers enhance the versatility of combine harvesters by allowing efficient harvesting of various crop types such as wheat, barley, and soybeans, minimizing crop loss and optimizing productivity. Compared to traditional reaper-binders, combine harvesters equipped with multi-crop headers reduce labor requirements and increase operational speed, delivering higher efficiency in large-scale agricultural operations.

GPS-Guided Swath Mapping

GPS-guided swath mapping in combine harvesters enables precise navigation and efficient crop collection by continuously monitoring and adjusting harvesting paths, reducing grain loss and overlap. In contrast, reaper-binders lack advanced GPS technology, leading to less accurate swath placement and increased manual adjustments during crop harvesting.

Reel-to-Cutterbar Synchronization

Combine harvesters provide superior reel-to-cutterbar synchronization compared to reaper-binders, enabling more efficient crop feeding and reduced grain loss during harvesting. Advanced sensor systems in combine harvesters adjust reel speed in real-time to match cutterbar operation, optimizing cutting quality and throughput under varying field conditions.

Drone-Assisted Harvest Assessment

Combine harvesters provide efficient, large-scale crop harvesting with integrated threshing and cleaning, while reaper-binders cut and bind crops for manual collection. Drone-assisted harvest assessment enhances precision by capturing real-time aerial data to monitor crop yields, detect field variability, and optimize the timing and method of harvest between combine harvesters and reaper-binders.

Telematics for Harvest Optimization

Combine harvesters equipped with advanced telematics systems provide real-time data on machine performance, crop yield, and field conditions, enhancing harvest optimization by enabling precise operational adjustments and predictive maintenance. In contrast, reaper-binders lack integrated telematics, limiting data-driven decision-making and efficiency improvements during crop harvesting.

On-Board Moisture Sensors

Combine harvesters equipped with advanced on-board moisture sensors enable real-time monitoring and precise adjustment of harvesting parameters, enhancing grain quality and reducing post-harvest losses. In contrast, reaper-binders lack integrated moisture measurement systems, resulting in less efficient crop drying and potential quality degradation during storage.

Eco-Friendly Binding Twines

Eco-friendly binding twines used in combine harvesters reduce environmental impact by decomposing naturally, minimizing plastic waste commonly associated with traditional reaper-binder twines. These biodegradable twines enhance sustainable crop harvesting, promoting soil health and reducing long-term ecological damage in agricultural practices.

Combine harvester vs Reaper-binder for crop harvesting Infographic

agridif.com

agridif.com