Chisel ploughs penetrate deep into the soil, breaking up compacted layers and improving aeration without inverting the soil, which helps preserve organic matter and reduce erosion. Disc harrows, on the other hand, cut and mix the topsoil surface effectively, making them suitable for chopping crop residues and preparing seedbeds but may cause greater soil disturbance and moisture loss. Choosing between a chisel plough and a disc harrow for primary tillage depends on soil type, crop requirements, and conservation goals to balance soil health and field efficiency.

Table of Comparison

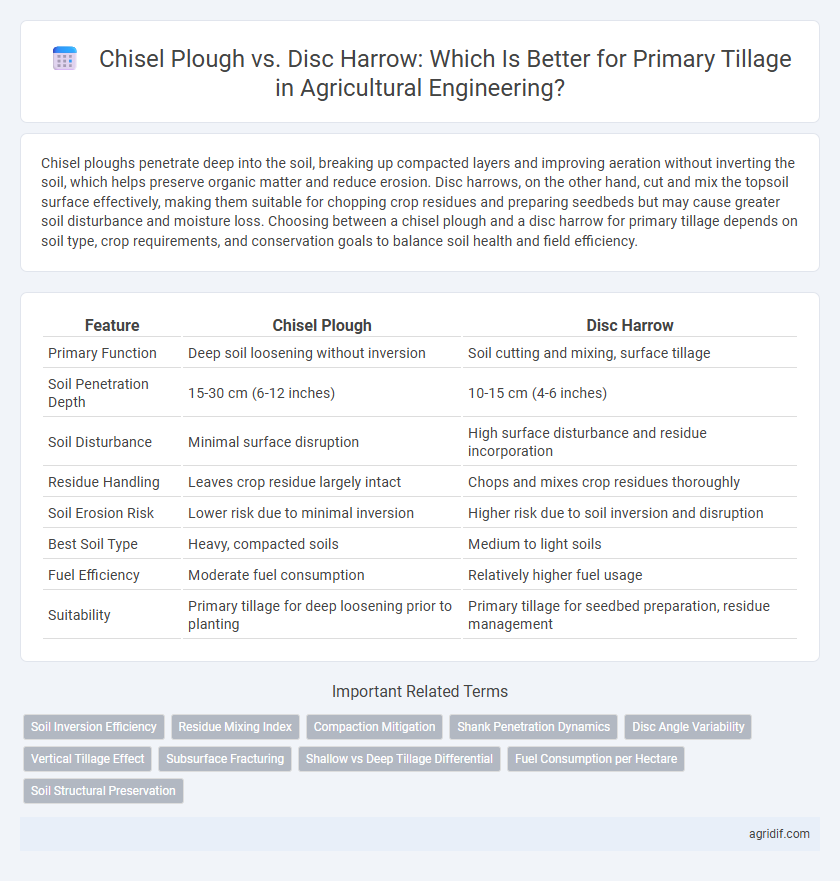

| Feature | Chisel Plough | Disc Harrow |

|---|---|---|

| Primary Function | Deep soil loosening without inversion | Soil cutting and mixing, surface tillage |

| Soil Penetration Depth | 15-30 cm (6-12 inches) | 10-15 cm (4-6 inches) |

| Soil Disturbance | Minimal surface disruption | High surface disturbance and residue incorporation |

| Residue Handling | Leaves crop residue largely intact | Chops and mixes crop residues thoroughly |

| Soil Erosion Risk | Lower risk due to minimal inversion | Higher risk due to soil inversion and disruption |

| Best Soil Type | Heavy, compacted soils | Medium to light soils |

| Fuel Efficiency | Moderate fuel consumption | Relatively higher fuel usage |

| Suitability | Primary tillage for deep loosening prior to planting | Primary tillage for seedbed preparation, residue management |

Introduction to Primary Tillage Implements

Chisel ploughs penetrate deep into the soil, breaking hardpan layers and improving aeration without inverting the soil, making them ideal for primary tillage in heavy or compacted soils. Disc harrows use a series of concave discs to slice and mix soil surface layers, effectively managing crop residues and preparing seedbeds, but they may cause soil compaction in finer-textured soils. Selecting between chisel ploughs and disc harrows depends on soil type, residue conditions, and the specific goals of tillage operations.

Overview of Chisel Plough: Design and Function

The chisel plough, featuring robust shanks and narrow, pointed tips, is designed for deep primary tillage with minimal soil disturbance. It efficiently breaks up compacted hardpan layers while preserving soil structure and moisture retention. This tool contrasts with the disc harrow's slicing action, making the chisel plough ideal for aerating heavy soils without extensive pulverization.

Overview of Disc Harrow: Design and Function

Disc harrows feature concave steel discs arranged on one or more axles, engineered to slice through soil, break clods, and incorporate crop residues efficiently during primary tillage. Their design enables effective soil mixing and leveling, improving seedbed preparation by enhancing aeration and moisture retention. Compared to chisel ploughs, disc harrows provide faster operation and better performance in surface residue management, especially in heavier or compacted soils.

Soil Penetration and Depth Comparison

The chisel plough offers superior soil penetration and deeper tillage compared to the disc harrow, effectively breaking compacted subsoil layers up to 30-40 cm deep. Disc harrows generally operate at shallower depths of 10-15 cm, making them more suitable for surface residue incorporation rather than deep soil loosening. In terms of soil penetration, the pointed shanks of the chisel plough create less soil disturbance but achieve greater depth, enhancing aeration and root growth in primary tillage operations.

Soil Structure Impact: Chisel Plough vs Disc Harrow

Chisel ploughs penetrate deeply into the soil, creating vertical fractures that enhance aeration and water infiltration while preserving the overall soil structure. Disc harrows, on the other hand, aggressively cut and mix the topsoil, which can lead to soil compaction and disruption of soil aggregates, negatively affecting soil porosity. For primary tillage, chisel ploughs are preferred when maintaining soil structure and minimizing erosion risk are priorities.

Residue Management and Crop Stubble Handling

Chisel ploughs excel in residue management by deeply loosening soil while leaving crop stubble relatively intact, promoting soil aeration and organic matter decomposition. Disc harrows effectively chop and mix crop residue into the soil, accelerating decomposition but potentially causing surface compaction. The choice between chisel plough and disc harrow for primary tillage depends on desired soil structure and residue incorporation intensity.

Energy and Fuel Efficiency Analysis

Chisel ploughs typically consume less energy and fuel compared to disc harrows due to their deeper penetration and reduced soil disturbance during primary tillage. Disc harrows require more horsepower and fuel because they cut and mix soil aggressively, increasing resistance and operational costs. Energy-efficient tillage practices favor chisel ploughs for conserving fuel while maintaining soil structure.

Suitability for Different Soil Types

Chisel ploughs perform exceptionally well in heavy clay and compacted soils due to their deep penetration and minimal soil disturbance, promoting better aeration and root growth. Disc harrows are more suitable for lighter, sandy, or loamy soils where they effectively break up surface clods and incorporate crop residues without causing excessive soil compaction. Selecting the appropriate implement depends on soil texture, moisture content, and intended tillage depth to optimize soil structure and crop yield.

Operational Costs and Maintenance Requirements

Chisel ploughs typically incur lower operational costs due to reduced fuel consumption and minimal soil disturbance, which prolongs equipment lifespan. Disc harrows require more frequent maintenance because of their multiple rotating discs and bearings, increasing downtime and expenses. Choosing a chisel plough can optimize long-term efficiency in primary tillage by balancing operational costs with maintenance demands.

Summary: Choosing the Right Implement for Primary Tillage

Chisel ploughs penetrate deeper soil layers, promoting aeration and minimizing soil compaction, making them ideal for breaking hardpan in primary tillage. Disc harrows excel at cutting and mixing surface residues, preparing a finer seedbed but with less depth penetration. Selecting between a chisel plough and a disc harrow depends on soil conditions, residue management goals, and desired tillage depth for optimal crop establishment.

Related Important Terms

Soil Inversion Efficiency

Chisel plough exhibits low soil inversion efficiency by loosening soil deeply without significant turning, preserving residue and minimizing erosion, whereas disc harrows demonstrate high soil inversion efficiency due to aggressive cutting and turning action that mixes soil layers effectively but can increase erosion risk. Selecting between these implements depends on balancing the need for residue retention and soil structure conservation against thorough soil mixing and weed control in primary tillage operations.

Residue Mixing Index

Chisel ploughs achieve a higher Residue Mixing Index by penetrating deeply into the soil, effectively incorporating crop residues without excessive soil inversion, which promotes better decomposition and soil health. Disc harrows tend to have a lower Residue Mixing Index due to their slicing action that mixes residues unevenly and often leaves more surface residue, potentially affecting moisture retention and microbial activity.

Compaction Mitigation

Chisel ploughs penetrate deeper soil layers, effectively breaking hardpan and reducing subsoil compaction without inverting the soil, which preserves soil structure and moisture. Disc harrows primarily fragment surface crusts with shallower action, offering limited compaction mitigation compared to the deeper loosening achieved by chisel ploughs in primary tillage.

Shank Penetration Dynamics

Chisel ploughs feature robust shanks designed for deeper and more consistent soil penetration, improving residue incorporation and soil aeration during primary tillage. In contrast, disc harrows rely on rotating discs that engage primarily at the soil surface, resulting in shallower penetration and less efficient disruption of compacted layers.

Disc Angle Variability

Disc harrows feature adjustable disc angles ranging from 0 to 30 degrees, allowing precise control over soil penetration and residue incorporation compared to the fixed tine configuration of chisel ploughs. Variable disc angles enhance primary tillage efficiency by optimizing soil breakup and clod size, improving seedbed preparation in diverse soil conditions.

Vertical Tillage Effect

Chisel plough provides deep soil penetration with minimal surface soil disturbance, enhancing vertical tillage by breaking compacted layers while preserving organic matter; disc harrow primarily cuts and mixes the surface soil, promoting lateral soil movement but less effective in alleviating subsurface compaction. Choosing chisel plough optimizes vertical tillage by improving soil aeration and water infiltration essential for root development in primary tillage operations.

Subsurface Fracturing

Chisel ploughs excel in subsurface fracturing by penetrating deeper into compacted soil layers, enhancing aeration and water infiltration without inverting the soil. Disc harrows primarily break up surface crusts and mix residues but have limited effect on deep soil compaction and subsurface loosening.

Shallow vs Deep Tillage Differential

Chisel ploughs perform deep tillage by loosening soil up to 20-30 cm, enhancing root penetration and water infiltration, while disc harrows provide shallow tillage, typically 10-15 cm, effectively managing surface residues and reducing soil compaction. Selecting chisel ploughs is ideal for breaking hardpan layers in heavy soils, whereas disc harrows are preferred for seedbed preparation in lighter soils requiring minimal soil disturbance.

Fuel Consumption per Hectare

Chisel ploughs generally consume less fuel per hectare compared to disc harrows due to their lower soil resistance and reduced draft requirements during primary tillage. Studies indicate that fuel consumption for chisel ploughing ranges from 15 to 20 liters per hectare, whereas disc harrowing can demand 20 to 30 liters per hectare under similar field conditions.

Soil Structural Preservation

Chisel ploughs maintain soil structural integrity by minimizing soil disturbance and preserving pore networks, which enhances water infiltration and reduces erosion risks during primary tillage. Disc harrows, while effective for breaking up surface crusts, tend to cause greater soil compaction and disrupt soil aggregates, leading to decreased structural preservation compared to chisel ploughs.

Chisel plough vs Disc harrow for primary tillage Infographic

agridif.com

agridif.com