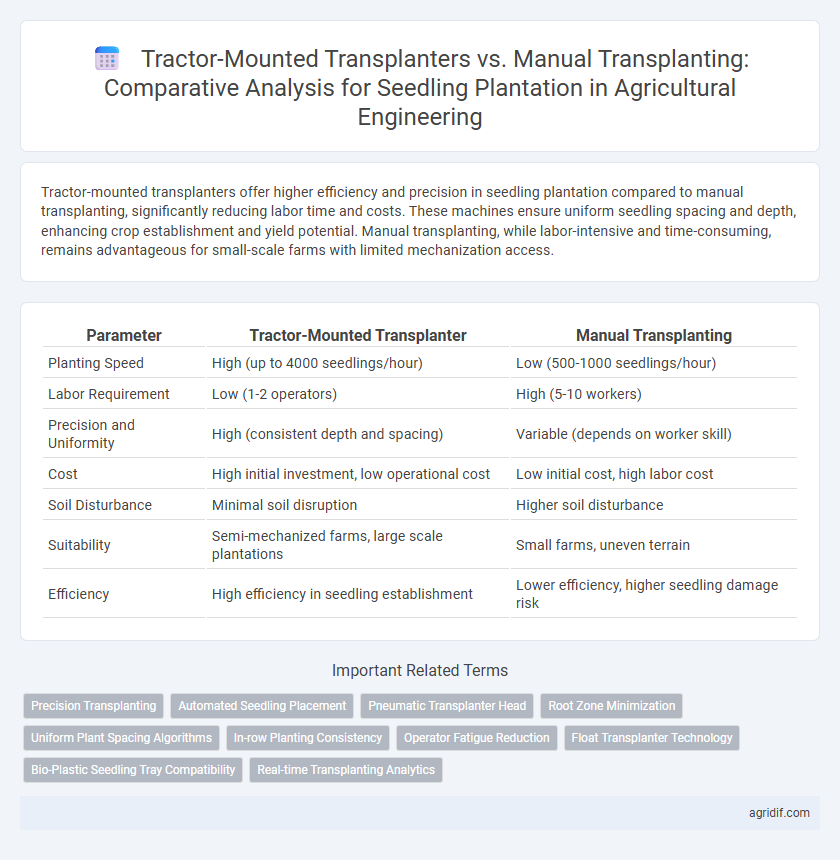

Tractor-mounted transplanters offer higher efficiency and precision in seedling plantation compared to manual transplanting, significantly reducing labor time and costs. These machines ensure uniform seedling spacing and depth, enhancing crop establishment and yield potential. Manual transplanting, while labor-intensive and time-consuming, remains advantageous for small-scale farms with limited mechanization access.

Table of Comparison

| Parameter | Tractor-Mounted Transplanter | Manual Transplanting |

|---|---|---|

| Planting Speed | High (up to 4000 seedlings/hour) | Low (500-1000 seedlings/hour) |

| Labor Requirement | Low (1-2 operators) | High (5-10 workers) |

| Precision and Uniformity | High (consistent depth and spacing) | Variable (depends on worker skill) |

| Cost | High initial investment, low operational cost | Low initial cost, high labor cost |

| Soil Disturbance | Minimal soil disruption | Higher soil disturbance |

| Suitability | Semi-mechanized farms, large scale plantations | Small farms, uneven terrain |

| Efficiency | High efficiency in seedling establishment | Lower efficiency, higher seedling damage risk |

Overview of Tractor-Mounted Transplanters

Tractor-mounted transplanters mechanize the seedling plantation process by efficiently spacing and planting seedlings at uniform depths, significantly increasing planting speed compared to manual transplanting. These machines reduce labor intensity and ensure consistent seedling placement, which enhances crop establishment and yield potential. Advanced models incorporate adjustable settings for various crop types and field conditions, optimizing performance and operational efficiency in large-scale agricultural operations.

Manual Transplanting: Traditional Practices

Manual transplanting involves the traditional practice of placing seedlings into prepared soil by hand, ensuring precise positioning and minimizing damage to young plants. Though labor-intensive and time-consuming, this method allows farmers to adjust seedling depth and spacing based on specific field conditions, enhancing early growth stages. Reliance on skilled labor and natural soil conditions often impacts transplanting efficiency and crop uniformity compared to mechanized alternatives.

Labor Efficiency Comparison

Tractor-mounted transplanters significantly enhance labor efficiency by reducing the time and physical effort required per hectare compared to manual transplanting. These machines enable precise and uniform seedling placement at a faster rate, often completing tasks in a fraction of the time needed for labor-intensive manual methods. Consequently, tractor-mounted transplanters reduce overall labor costs while increasing productivity in seedling plantation operations.

Field Operation Speed and Productivity

Tractor-mounted transplanters significantly enhance field operation speed by planting seedlings at a consistent rate of 20,000 to 25,000 plants per hour, compared to manual transplanting, which achieves only 5,000 to 8,000 plants per hour. This mechanized approach improves productivity by reducing labor intensity and ensuring uniform seedling placement, thereby optimizing crop establishment and growth. The higher operational efficiency of tractor-mounted transplanters directly contributes to increased acreage coverage within a shorter period, maximizing overall agricultural output.

Cost Analysis: Initial and Operating Expenses

Tractor-mounted transplanters incur higher initial costs due to machinery investment and fuel consumption but significantly reduce labor expenses compared to manual transplanting. Manual transplanting demands minimal upfront capital yet involves considerable ongoing labor costs, especially in large-scale operations. Over time, tractor-mounted transplanters offer better cost efficiency and higher productivity by minimizing manual labor and transplanting time.

Seedling Survival and Establishment Rates

Tractor-mounted transplanters significantly improve seedling survival and establishment rates compared to manual transplanting by ensuring consistent depth and spacing, reducing seedling shock and damage. Mechanized transplanting enhances root-soil contact, promoting better nutrient uptake and quicker adaptation to field conditions. Studies report survival rates of over 90% with tractor-mounted transplanters, while manual methods often show variable rates due to human error and labor fatigue.

Precision and Uniformity in Planting

Tractor-mounted transplanters ensure higher precision and uniformity in seedling plantation by mechanically spacing plants at consistent intervals and depths, reducing human error compared to manual transplanting. This mechanized method enhances crop establishment and growth uniformity, leading to improved resource utilization and yield potential. Manual transplanting often results in irregular spacing and variable planting depths, which can compromise plant development and overall field productivity.

Ergonomic and Labor Health Implications

Tractor-mounted transplanters significantly reduce physical strain and repetitive motions associated with manual seedling transplantation, lowering risks of musculoskeletal disorders among workers. These mechanized systems improve ergonomic conditions by minimizing bending, squatting, and prolonged standing, common in manual methods. Enhanced labor health outcomes result from decreased exposure to fatigue and repetitive stress injuries, promoting sustainable workforce productivity in agricultural operations.

Suitability for Different Crops and Scales

Tractor-mounted transplanters are highly suitable for large-scale cultivation of uniform crops like rice and vegetables, enabling precise seedling spacing and faster planting compared to manual transplanting. Manual transplanting remains ideal for small-scale farms and irregularly shaped fields where crop variety and planting density vary significantly, allowing flexibility in handling delicate or diverse seedlings. The choice depends on crop type, field size, and labor availability, with mechanized transplanters enhancing efficiency for commercial farming operations.

Environmental Impact and Sustainability

Tractor-mounted transplanters reduce soil compaction and fuel consumption compared to manual transplanting by optimizing energy use and minimizing repetitive tillage, which enhances soil carbon sequestration and reduces greenhouse gas emissions. Improved planting uniformity and crop density achieved by mechanized transplanting increase resource use efficiency, leading to sustainable water and fertilizer application. This mechanization lowers labor dependence and mitigates deforestation risks associated with manual transplantation in sloped or remote areas, promoting environmental sustainability in agricultural landscapes.

Related Important Terms

Precision Transplanting

Tractor-mounted transplanters offer precision transplanting by ensuring consistent seedling depth and spacing, significantly improving crop uniformity and reducing labor costs compared to manual transplanting. This mechanized method enhances planting efficiency and optimizes field productivity by minimizing human error and ensuring optimal seedling placement.

Automated Seedling Placement

Tractor-mounted transplanters enhance precision in automated seedling placement by ensuring uniform spacing and consistent depth, significantly increasing planting efficiency and reducing labor costs compared to manual transplanting. This mechanized approach minimizes seedling damage and optimizes crop establishment, leading to improved yield potential and resource utilization in agricultural operations.

Pneumatic Transplanter Head

The pneumatic transplanter head in tractor-mounted transplanters enhances seedling placement accuracy and uniformity compared to manual transplanting, significantly increasing planting efficiency and reducing labor costs. This technology also minimizes seedling damage and ensures consistent soil contact, promoting better crop establishment and higher yields.

Root Zone Minimization

Tractor-mounted transplanters significantly reduce root zone disturbance by precisely placing seedlings at uniform depths with minimal soil disruption, enhancing root establishment and reducing transplant shock. Manual transplanting often causes irregular planting depths and larger root zone damage, leading to inconsistent seedling growth and lower crop yields.

Uniform Plant Spacing Algorithms

Tractor-mounted transplanters utilize advanced uniform plant spacing algorithms that ensure precise and consistent seedling placement, optimizing growth conditions and crop yield. Manual transplanting often results in irregular spacing, reducing planting efficiency and leading to uneven crop development and potential resource wastage.

In-row Planting Consistency

Tractor-mounted transplanters ensure precise in-row planting consistency by placing seedlings at uniform depths and intervals, significantly reducing seedling damage and labor intensity compared to manual transplanting. Manual transplanting often results in irregular spacing and depth variation, leading to uneven crop emergence and reduced overall yield potential.

Operator Fatigue Reduction

Tractor-mounted transplanters significantly reduce operator fatigue compared to manual transplanting by mechanizing the repetitive process of seedling placement, allowing for continuous planting with minimal physical exertion. This technology enhances efficiency by minimizing the bending and walking labor-intensive activities inherent in manual methods, leading to improved ergonomics and sustained operator productivity during extended planting sessions.

Float Transplanter Technology

Tractor-mounted float transplanter technology significantly enhances seedling plantation efficiency by ensuring uniform spacing and depth, reducing labor costs by up to 70% compared to manual transplanting methods. This mechanized approach minimizes seedling damage and increases planting speed to over 6000 seedlings per hour, promoting higher crop yields and consistent field establishment.

Bio-Plastic Seedling Tray Compatibility

Tractor-mounted transplanters are designed to accommodate bio-plastic seedling trays, offering enhanced compatibility by reducing seedling damage and improving planting precision compared to manual transplanting. Bio-plastic trays combined with mechanized transplanting increase environmental sustainability while optimizing field efficiency and uniform crop establishment.

Real-time Transplanting Analytics

Tractor-mounted transplanters provide real-time transplanting analytics by integrating GPS and sensor technologies to monitor planting depth, spacing, and seedling vigor, significantly enhancing precision and efficiency compared to manual transplanting. This data-driven approach reduces labor costs, improves crop uniformity, and enables timely decision-making for optimized seedling establishment.

Tractor-mounted transplanter vs Manual transplanting for seedling plantation Infographic

agridif.com

agridif.com