Combine harvesters efficiently reap, thresh, and clean grain crops in a single pass, making them ideal for cereals like wheat and corn. Forage harvesters specialize in chopping green plants such as maize and grass into silage, preserving nutritional value for livestock feed. Choosing between them depends on crop type and end-use, with combine harvesters suited for grain collection and forage harvesters optimized for fodder preparation.

Table of Comparison

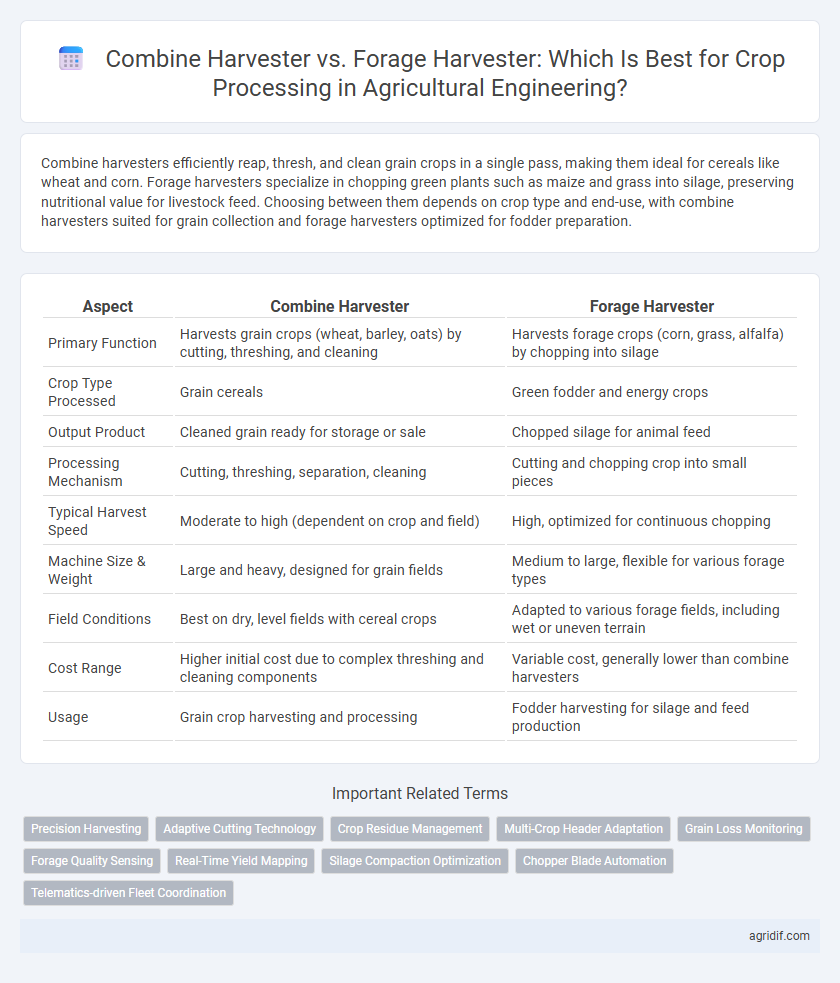

| Aspect | Combine Harvester | Forage Harvester |

|---|---|---|

| Primary Function | Harvests grain crops (wheat, barley, oats) by cutting, threshing, and cleaning | Harvests forage crops (corn, grass, alfalfa) by chopping into silage |

| Crop Type Processed | Grain cereals | Green fodder and energy crops |

| Output Product | Cleaned grain ready for storage or sale | Chopped silage for animal feed |

| Processing Mechanism | Cutting, threshing, separation, cleaning | Cutting and chopping crop into small pieces |

| Typical Harvest Speed | Moderate to high (dependent on crop and field) | High, optimized for continuous chopping |

| Machine Size & Weight | Large and heavy, designed for grain fields | Medium to large, flexible for various forage types |

| Field Conditions | Best on dry, level fields with cereal crops | Adapted to various forage fields, including wet or uneven terrain |

| Cost Range | Higher initial cost due to complex threshing and cleaning components | Variable cost, generally lower than combine harvesters |

| Usage | Grain crop harvesting and processing | Fodder harvesting for silage and feed production |

Introduction to Crop Processing Machinery

Combine harvesters efficiently perform multiple crop processing tasks, including reaping, threshing, and cleaning grain crops like wheat and rice in a single operation. Forage harvesters specialize in chopping and collecting green plants, such as corn and grass, for silage production, optimizing feed quality for livestock. Selecting the appropriate machinery depends on the crop type and desired end product, crucial for maximizing efficiency in modern agricultural operations.

Overview: Combine Harvester and Forage Harvester

Combine harvesters efficiently perform multiple crop processing tasks, including reaping, threshing, and winnowing, primarily used for cereals like wheat and rice. Forage harvesters specialize in chopping and gathering green crops such as maize and grasses to produce silage for animal feed. Both machines enhance agricultural productivity but serve distinct roles in crop harvesting and post-harvest processing.

Key Functions and Mechanisms

Combine harvesters efficiently perform crop threshing, separating, and cleaning in a single operation, primarily designed for cereals like wheat and barley. Forage harvesters specialize in chopping and processing whole plants such as corn and grass into silage, utilizing powerful cutting mechanisms and high-speed choppers. The key distinction lies in the combine's ability to separate grain from the straw, whereas forage harvesters focus on producing finely chopped feed for livestock.

Crop Types Suited for Each Harvester

Combine harvesters are primarily designed for cereal crops such as wheat, barley, oats, rye, and corn, efficiently cutting, threshing, and cleaning grains in one operation. Forage harvesters specialize in harvesting forage crops like alfalfa, clover, grasses, and whole-plant corn, finely chopping them for silage production. Each harvester optimizes crop processing by matching specific crop types to their mechanical design and harvesting techniques.

Efficiency in Harvesting and Processing

Combine harvesters excel in efficiency by simultaneously reaping, threshing, and cleaning grains, significantly reducing time and labor for cereal crop processing. Forage harvesters are specialized for chopping and collecting high-moisture crops like maize and grasses, optimizing feed quality and preservation for livestock. Choosing between the two depends on crop type and processing needs, with combine harvesters best suited for grain crops and forage harvesters ideal for silage production.

Quality of Output: Grain vs. Forage Material

Combine harvesters excel in grain processing by efficiently threshing and separating kernels, resulting in high-quality, clean grain suitable for storage and sale. Forage harvesters specialize in chopping and collecting whole plants into uniform forage material, optimizing feed quality for livestock through precise moisture control and minimal leaf shatter. Quality of output in both machines directly impacts post-harvest handling, storage longevity, and overall crop value in agricultural production.

Fuel Consumption and Operational Costs

Combine harvesters typically consume less fuel per hectare compared to forage harvesters due to their integrated threshing and separation processes, optimizing fuel efficiency in grain crop harvesting. Operational costs for combine harvesters are generally lower as they perform multiple functions in a single pass, reducing labor and time expenditures. In contrast, forage harvesters incur higher fuel consumption owing to their specialized chopping and processing mechanisms, leading to increased maintenance and operational expenses.

Technological Features and Automation

Combine harvesters integrate cutting, threshing, and cleaning processes with advanced sensors and GPS for precision agriculture, enabling efficient grain harvesting with automated yield monitoring. Forage harvesters specialize in chopping and collecting forage crops using high-speed spindles and kernel processors, equipped with automation features like moisture sensors and crop flow control to optimize silage quality. Both machines incorporate real-time data analytics and GPS-guided technology to enhance operational accuracy, reduce labor, and increase productivity in crop processing.

Maintenance and Durability Comparison

Combine harvesters require regular maintenance of cutting blades, threshing components, and sieves to ensure optimal performance and longevity, with durability dependent on robust engine design and quality materials that resist wear from crop residue. Forage harvesters demand frequent servicing of chopping knives, feed rolls, and hydraulic systems due to high mechanical stress and moisture exposure, while their durability hinges on reinforced structural parts designed to withstand continuous heavy-duty operation. Both machines benefit from preventive maintenance schedules and use of genuine spare parts to maximize service life and reduce downtime in crop processing tasks.

Choosing the Right Harvester for Farm Needs

Selecting the right harvester depends on crop type and processing goals, with combine harvesters ideal for grains like wheat and corn, while forage harvesters excel in chopping silage crops such as maize and grass. Combine harvesters integrate reaping, threshing, and winnowing, optimizing grain collection efficiency, whereas forage harvesters provide specialized chopping and conditioning for livestock feed quality. Considering factors like field size, crop moisture, and machinery versatility ensures optimal harvest timing and farm productivity.

Related Important Terms

Precision Harvesting

Combine harvesters optimize grain yield by integrating cutting, threshing, and cleaning in a single pass, while forage harvesters specialize in chopping and collecting silage crops with precise moisture control for quality feedstock. Precision harvesting technologies in both machines utilize GPS and sensor-based systems to enhance efficiency, reduce crop loss, and improve data-driven decision-making in agricultural operations.

Adaptive Cutting Technology

Combine harvesters equipped with Adaptive Cutting Technology optimize grain and straw separation by adjusting cutting height and blade speed based on crop density and moisture levels, enhancing yield quality and minimizing losses. In contrast, forage harvesters utilize similar adaptive systems to precisely chop silage crops, ensuring uniform particle size and improved feed digestibility for livestock nutrition.

Crop Residue Management

Combine harvesters efficiently separate grain from crop residue, leaving straw and chaff on the field for natural decomposition or subsequent mulching, which enhances soil organic matter and reduces erosion. Forage harvesters chop entire plant biomass, including stalks and leaves, into small pieces ideal for silage, resulting in minimal crop residue left in the field and necessitating additional residue management practices to maintain soil health.

Multi-Crop Header Adaptation

Combine harvesters equipped with multi-crop headers offer versatile harvesting solutions by efficiently processing grains like wheat, barley, and corn, optimizing yield and reducing crop loss. Forage harvesters, while specialized for chopping and collecting silage crops such as corn and grass, require specific header adaptations to handle diverse forage types but excel in biomass preparation for livestock feed.

Grain Loss Monitoring

Combine harvesters employ advanced sensors and real-time grain loss monitoring systems to optimize harvesting efficiency by minimizing grain spillage in cereal crops. Forage harvesters, primarily designed for chopping crops like corn and grass, integrate grain loss monitoring to a lesser extent, focusing more on biomass quality and output rather than precise grain recovery.

Forage Quality Sensing

Forage harvesters equipped with advanced forage quality sensing technology enable real-time analysis of moisture, fiber, and nutrient content, optimizing crop processing and feed value. Unlike combine harvesters primarily designed for grain separation, forage harvesters focus on preserving the nutritional integrity of silage, thus enhancing livestock productivity through precise quality monitoring.

Real-Time Yield Mapping

Combine harvesters equipped with real-time yield mapping utilize GPS and sensor technology to measure grain output and moisture content during harvesting, enabling precise field-specific management decisions. Forage harvesters integrate yield monitors that track biomass volume and quality metrics in real time, optimizing silage production and enhancing nutrient management strategies.

Silage Compaction Optimization

Combine harvesters primarily focus on grain separation and threshing, whereas forage harvesters are engineered to optimize silage quality through precise chopping and uniform particle size, which enhances compaction and fermentation efficiency. Effective silage compaction achieved by forage harvesters reduces oxygen presence, improves anaerobic microbial activity, and preserves nutrient content, resulting in higher-quality silage for livestock feed.

Chopper Blade Automation

Combine harvesters equipped with advanced chopper blade automation systems enhance efficiency by precisely controlling blade speed and cutting length for diverse crops, optimizing grain separation and straw chopping. In contrast, forage harvesters utilize automated chopper blades designed to maximize fiber preservation and particle size uniformity, crucial for high-quality silage production and livestock nutrition.

Telematics-driven Fleet Coordination

Combine harvesters equipped with telematics enable real-time data sharing on crop yield, machine performance, and field conditions, optimizing route planning and minimizing downtime during grain harvesting. Forage harvesters integrated with telematics improve synchronization in biomass collection by providing precise location tracking and operational metrics, enhancing fleet coordination and ensuring efficient crop processing.

Combine harvester vs Forage harvester for crop processing Infographic

agridif.com

agridif.com