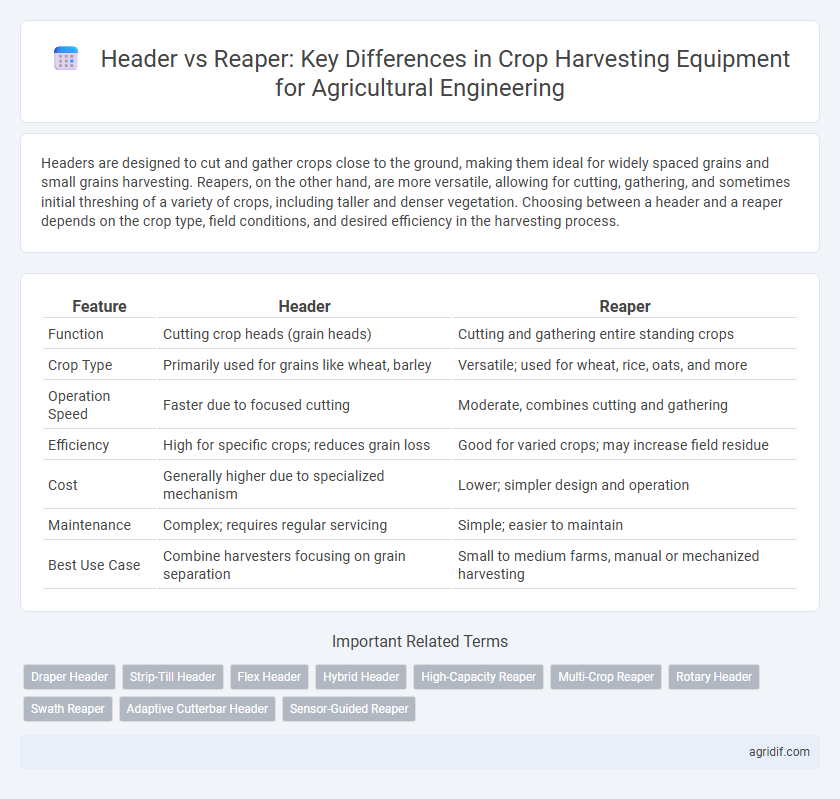

Headers are designed to cut and gather crops close to the ground, making them ideal for widely spaced grains and small grains harvesting. Reapers, on the other hand, are more versatile, allowing for cutting, gathering, and sometimes initial threshing of a variety of crops, including taller and denser vegetation. Choosing between a header and a reaper depends on the crop type, field conditions, and desired efficiency in the harvesting process.

Table of Comparison

| Feature | Header | Reaper |

|---|---|---|

| Function | Cutting crop heads (grain heads) | Cutting and gathering entire standing crops |

| Crop Type | Primarily used for grains like wheat, barley | Versatile; used for wheat, rice, oats, and more |

| Operation Speed | Faster due to focused cutting | Moderate, combines cutting and gathering |

| Efficiency | High for specific crops; reduces grain loss | Good for varied crops; may increase field residue |

| Cost | Generally higher due to specialized mechanism | Lower; simpler design and operation |

| Maintenance | Complex; requires regular servicing | Simple; easier to maintain |

| Best Use Case | Combine harvesters focusing on grain separation | Small to medium farms, manual or mechanized harvesting |

Introduction to Crop Harvesting Technologies

Headers and reapers are fundamental crop harvesting technologies designed to enhance efficiency and reduce labor costs in agricultural engineering. Headers are attachments for combines that cut and gather crops such as wheat, barley, and corn, streamlining the harvesting process by simultaneously reaping and threshing. Reapers, on the other hand, are specialized machines that cut crops at the base but require separate threshing, offering versatility for small-scale farms and diverse crop types.

Overview of Headers and Reapers

Headers are attachments mounted on combines designed to cut and gather crops such as wheat, barley, and soybeans efficiently, optimizing the harvesting process by directing crops into the threshing mechanism. Reapers are standalone machines primarily used for cutting crops like rice and wheat, enabling manual or semi-mechanical harvesting with less dependency on large equipment. Both headers and reapers are essential in agricultural engineering for maximizing crop yield and reducing labor intensity during harvest.

Working Principles: Header vs Reaper

Headers and reapers are crucial agricultural implements designed for crop harvesting, with distinct working principles. A header attached to a combine harvester cuts and gathers crops before feeding them into the threshing mechanism, enabling simultaneous cutting and processing of grains such as wheat, rice, and barley. In contrast, a reaper manually or mechanically cuts crops at the base and lays them down in bundles, primarily used for harvesting cereals and fodder, requiring additional steps for threshing and collection.

Types of Headers and Reapers

Headers in agricultural engineering include types like grain platforms, corn heads, and flex heads, each designed to optimize the cutting and feeding of specific crops such as wheat, corn, and soybeans. Reapers, differentiated by manual, self-propelled, and tractor-mounted varieties, specialize in cutting and gathering crops like rice and wheat, enhancing harvesting efficiency. Choosing the right header or reaper depends on crop type, field conditions, and machinery compatibility to maximize yield and minimize grain loss.

Efficiency and Performance Comparison

Headers offer precise cutting and efficient crop gathering ideal for small to medium-scale farming, providing minimal grain loss and high throughput rates. Reapers, while less specialized, excel in versatility across various crop types and rough terrains, delivering faster harvesting speeds but often at the cost of increased grain loss. Evaluating efficiency involves balancing the header's crop-specific optimization against the reaper's adaptability and speed for overall performance.

Suitability for Different Crops

Headers are typically more suitable for cereal grains such as wheat, barley, and oats, efficiently cutting and gathering the crop. Reapers excel in harvesting fodder crops like grass and legumes, providing a cleaner cut with minimal crop damage. Crop moisture content and stalk thickness influence the choice, with headers preferred for sturdier grains and reapers ideal for delicate or leafy crops.

Operational Costs and Maintenance

Headers typically incur lower operational costs and reduced maintenance due to their simpler mechanical design and fewer moving parts compared to reapers. Reapers, while versatile for multiple crop types, demand higher maintenance expenditures stemming from more complex cutting and threshing mechanisms. Optimizing harvesting equipment selection based on crop type and field conditions can significantly impact long-term cost efficiency and reliability.

Technological Advancements in Harvesting Equipment

Headers have evolved with advanced cutting mechanisms and adjustable reel speeds to enhance crop harvesting efficiency. Reapers integrate automated steering systems and sensor-based crop detection to minimize losses and improve precision. Both technologies leverage GPS guidance and telematics to optimize field operation and reduce labor costs in modern agricultural engineering.

Environmental Impact and Sustainability

Headers and reapers differ significantly in their environmental impact and sustainability during crop harvesting. Headers, which cut and collect crops more efficiently, reduce soil disturbance and residue loss, promoting better soil health and carbon sequestration. Reapers, while simpler and less expensive, often cause increased soil compaction and organic matter loss, resulting in higher long-term environmental degradation compared to headers.

Choosing the Right Equipment for Your Farm

Selecting between a header and a reaper depends on the crop type and farm size, as headers are ideal for large-scale combines harvesting cereals like wheat and barley, while reapers excel in small to medium farms harvesting crops such as rice and maize. Efficiency metrics show that headers increase harvesting speed and reduce grain loss in mechanized operations, whereas reapers offer precision cutting suitable for uneven terrains and mixed cropping patterns. Investing in the appropriate equipment enhances productivity, minimizes labor costs, and aligns with specific crop characteristics, ultimately improving overall farm profitability.

Related Important Terms

Draper Header

Draper headers outperform traditional reel and sickle headers by using conveyor belts to smoothly transfer crops, reducing grain loss and enhancing harvesting efficiency for cereals like wheat and barley. Their flexible design adapts to uneven terrain and varying crop conditions, making them ideal for high-yield agricultural operations seeking minimized residue and faster field coverage.

Strip-Till Header

The Strip-Till Header combines the precision of strip-till farming with efficient crop harvesting, minimizing soil disturbance while maximizing residue management compared to traditional Reapers. This innovation enhances soil health and boosts yield by preserving moisture and reducing erosion during the harvest process.

Flex Header

Flex headers offer superior flexibility for harvesting uneven terrain and crops with ground-level pods, enhancing efficiency and minimizing crop loss compared to rigid headers. Their articulated design adapts to field contours, making them especially effective for soybeans and other low-growing crops.

Hybrid Header

Hybrid headers combine the precision of traditional headers with the efficiency of reapers, enhancing crop harvesting by minimizing grain loss and maximizing throughput in diverse field conditions. Their advanced design supports a wider range of crop types, increases operational speed, and improves adaptability compared to standard headers or standalone reapers.

High-Capacity Reaper

High-capacity reapers offer faster and more efficient crop harvesting compared to traditional headers, significantly reducing labor and operational time in large-scale agricultural fields. Their advanced cutting mechanisms and integrated threshing systems optimize grain quality and minimize crop loss, making them ideal for extensive cereal crop production.

Multi-Crop Reaper

Multi-Crop Reapers offer versatile harvesting capabilities across various crops like wheat, barley, and maize, outperforming traditional headers by reducing crop loss and improving efficiency through adjustable cutting heights and automated threshing. Their advanced design integrates cutting, gathering, and threshing processes in one machine, enhancing productivity and minimizing labor costs compared to single-purpose headers.

Rotary Header

Rotary headers excel in crop harvesting by efficiently cutting and feeding crops into the combine harvester with minimal losses, outperforming traditional reel-based headers in handling lodged or high-moisture crops. Their design incorporates rotating blades that provide smoother crop flow and reduced grain damage, making them ideal for diverse field conditions and maximizing yield quality.

Swath Reaper

Swath reapers offer precise crop cutting with minimal machine damage, making them ideal for delicate crops and uneven terrains compared to traditional headers. Their design enhances harvesting efficiency by laying crops in uniform swaths, facilitating faster and cleaner collection.

Adaptive Cutterbar Header

The Adaptive Cutterbar Header enhances crop harvesting efficiency by automatically adjusting blade height and angle to varying field conditions, minimizing grain loss and crop damage compared to traditional reapers. This technology integrates sensor feedback and hydraulic controls to optimize cutting performance and reduce operator fatigue during complex harvesting operations.

Sensor-Guided Reaper

Sensor-Guided Reapers enhance crop harvesting efficiency by using advanced sensors to accurately detect crop height, density, and maturity, enabling precise cutting with minimal crop loss compared to traditional headers. This technology reduces operator fatigue and increases productivity by automating adjustments in real-time, optimizing the harvest process across varying field conditions.

Header vs Reaper for crop harvesting Infographic

agridif.com

agridif.com