Flat belts offer higher speed capacity and easier alignment for agricultural machinery drives, reducing slippage and maintenance needs. V-belts provide superior power transmission efficiency and better grip under heavy loads, making them ideal for high-torque applications in agricultural equipment. Selecting between flat belts and V-belts depends on the specific machinery requirements, load conditions, and operational efficiency goals in farming operations.

Table of Comparison

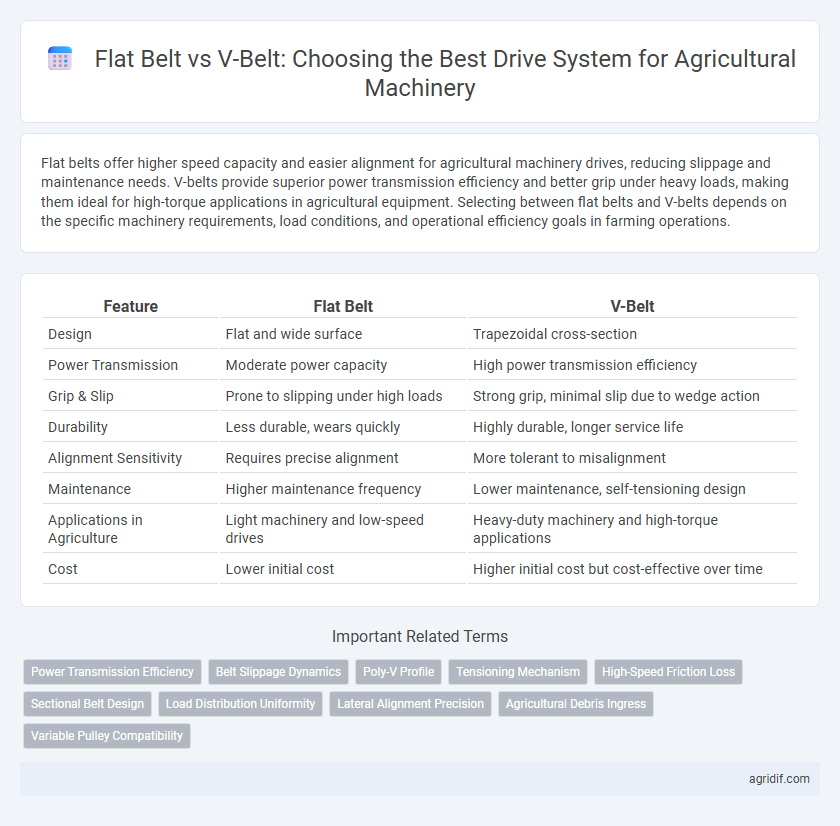

| Feature | Flat Belt | V-Belt |

|---|---|---|

| Design | Flat and wide surface | Trapezoidal cross-section |

| Power Transmission | Moderate power capacity | High power transmission efficiency |

| Grip & Slip | Prone to slipping under high loads | Strong grip, minimal slip due to wedge action |

| Durability | Less durable, wears quickly | Highly durable, longer service life |

| Alignment Sensitivity | Requires precise alignment | More tolerant to misalignment |

| Maintenance | Higher maintenance frequency | Lower maintenance, self-tensioning design |

| Applications in Agriculture | Light machinery and low-speed drives | Heavy-duty machinery and high-torque applications |

| Cost | Lower initial cost | Higher initial cost but cost-effective over time |

Introduction to Flat Belt and V-Belt Drive Systems

Flat belt drive systems utilize a wide, flat belt running over pulleys for efficient power transmission in agricultural machinery, offering simplicity and ease of adjustment. V-belt drive systems feature a trapezoidal cross-section belt that fits into matching pulley grooves, providing higher friction and preventing slippage under heavy loads. Both flat and V-belts serve critical roles in drive systems, with selection influenced by factors such as power requirements, pulley design, and operating conditions in agricultural equipment.

Principle of Operation: Flat Belt vs V-Belt

Flat belts operate on the principle of friction between the flat surface of the belt and the pulleys, relying on tension to transmit power efficiently in agricultural machinery drive systems. V-belts function by wedging into the grooves of V-shaped pulleys, which increases the contact pressure and enhances grip, enabling higher torque transmission and reduced slippage. This design difference makes V-belts more suitable for high-load applications in agricultural equipment compared to flat belts.

Advantages of Flat Belts in Agricultural Machinery

Flat belts in agricultural machinery offer superior flexibility and ease of installation compared to V-belts, allowing for smoother power transmission across varying shaft distances. They provide reduced slippage and better shock absorption, which enhances the durability of equipment like threshers and conveyors. The lower maintenance requirements and cost-effectiveness of flat belts make them ideal for heavy-duty agricultural applications where consistent performance is crucial.

Benefits of V-Belts for Agricultural Applications

V-belts provide superior power transmission efficiency and enhanced grip, reducing slippage in agricultural machinery drive systems. Their compact design and ability to absorb shock loads improve durability and extend the lifespan of equipment such as tractors and combine harvesters. V-belts also enable easier maintenance and replacement, minimizing downtime during critical farming operations.

Power Transmission Efficiency: Flat Belt vs V-Belt

V-belts offer higher power transmission efficiency compared to flat belts due to their wedging action inside the pulley groove, which reduces slippage and increases friction. Flat belts experience more slip and require precise tensioning to maintain efficiency, making them less effective for transmitting high power loads. In agricultural machinery drive systems, V-belts are preferred for their durability and consistent power transfer under varying loads and conditions.

Maintenance Requirements and Lifespan Comparison

Flat belts require regular tension adjustments and alignment checks to prevent slippage and wear, often needing more frequent maintenance than V-belts. V-belts, designed with a trapezoidal cross-section, provide better grip and distribute load evenly, resulting in longer lifespan and reduced maintenance intervals. Agricultural machinery relying on V-belts benefits from enhanced durability and less frequent service, enhancing overall operational efficiency.

Cost Analysis: Flat Belt vs V-Belt Systems

Flat belts generally offer a lower initial cost compared to V-belts due to simpler manufacturing and installation processes in agricultural machinery drive systems. V-belts, although more expensive upfront, provide enhanced durability and efficiency, reducing long-term maintenance and replacement expenses in demanding agricultural environments. Analyzing total cost of ownership reveals that V-belt systems often deliver better value in high-torque applications despite higher initial investment.

Suitability for Varying Loads and Speed Ranges

V-belts provide superior grip and efficiency for machinery drive systems operating under varying loads and speed ranges due to their wedging action in the pulley groove, reducing slippage. Flat belts are more suited for consistent speed and lighter loads but tend to slip under variable or heavy load conditions, limiting their effectiveness in dynamic agricultural environments. V-belts also accommodate wider speed variations with enhanced durability, making them ideal for fluctuating operational demands in agricultural engineering applications.

Safety Considerations in Agricultural Belt Drives

Flat belts in agricultural machinery offer less grip and higher slippage risk compared to V-belts, increasing the chances of accidental disengagement and potential injury during operation. V-belts provide superior tension control and reduced slip, enhancing safety by maintaining consistent power transmission and minimizing sudden machine stoppages. Proper installation and regular maintenance of V-belts are critical for preventing belt failure and ensuring operator safety in agricultural drive systems.

Choosing the Right Belt Drive for Farm Machinery

Selecting the right belt drive for farm machinery hinges on efficiency and durability, where V-belts offer superior grip and power transmission for heavy loads compared to flat belts. Flat belts excel in applications requiring high speed and low power, providing smoother operation and easier maintenance due to their simpler design. Prioritizing factors like load capacity, operational environment, and alignment requirements ensures optimal performance and longevity in agricultural equipment.

Related Important Terms

Power Transmission Efficiency

V-belts provide higher power transmission efficiency than flat belts due to their wedge-shaped design, which increases friction and reduces slip in agricultural machinery drive systems. Flat belts, while simpler and easier to maintain, often suffer from lower grip and higher slippage, resulting in decreased efficiency under heavy load conditions.

Belt Slippage Dynamics

Flat belts exhibit higher slippage rates due to lower friction coefficients between the belt surface and pulleys, impacting precise machinery drive systems in agricultural engineering. V-belts, with their wedge-shaped cross-section, enhance grip by increasing contact pressure within pulley grooves, significantly reducing belt slippage dynamics and improving power transmission efficiency in diverse field equipment.

Poly-V Profile

Poly-V belts in agricultural machinery drive systems offer superior flexibility and higher power transmission efficiency compared to flat belts, making them ideal for compact layouts and high-speed applications. Unlike traditional V-belts, Poly-V profiles combine multiple longitudinal ribs that enhance grip and reduce slippage, increasing durability and operational reliability in demanding agricultural environments.

Tensioning Mechanism

Flat belts require manual tensioning using adjustable pulleys or idler pulleys to maintain proper grip and prevent slippage in agricultural machinery drive systems. V-belts offer self-tensioning advantages with their wedge-shaped design, providing improved grip and reduced maintenance through automatic tension adjustments during operation.

High-Speed Friction Loss

V-belts exhibit lower high-speed friction loss compared to flat belts due to their wedged cross-section, which enhances grip and reduces slippage in agricultural machinery drive systems. This improved power transmission efficiency minimizes energy waste and reduces heat generation, leading to longer belt life and more reliable high-speed operation in harvesting and planting equipment.

Sectional Belt Design

Flat belts in agricultural machinery drive systems offer smoother power transmission with less vibration, suitable for high-speed, low-torque applications, whereas V-belts provide superior grip and load-carrying capacity due to their wedging action inside pulley grooves, ideal for moderate to high-torque demands. Sectional belt design enhances maintenance efficiency by allowing individual segment replacement, reducing downtime and ensuring consistent tension, which is critical for optimizing drive system performance in varying agricultural environments.

Load Distribution Uniformity

Flat belts provide more uniform load distribution across the entire belt width, reducing localized wear and increasing the lifespan of agricultural machinery drive systems. V-belts concentrate load on the belt's angled edges, which can lead to uneven stress and quicker deterioration under heavy or variable loads common in farming equipment.

Lateral Alignment Precision

Flat belts require higher lateral alignment precision due to their larger contact surface and tendency to slip under misalignment, making them less forgiving in agricultural machinery drive systems. V-belts offer better lateral tracking and grip within pulleys' grooves, reducing slippage and improving efficiency in power transmission where slight misalignment is common.

Agricultural Debris Ingress

Flat belts are more susceptible to agricultural debris ingress due to their larger contact surface and open design, leading to frequent slippage and reduced efficiency in farming machinery drive systems. V-belts offer better protection against debris infiltration with their deeper, enclosed grooves, enhancing grip and durability in harsh agricultural environments.

Variable Pulley Compatibility

Flat belts exhibit superior variable pulley compatibility due to their flexible nature, allowing seamless adjustment in agricultural machinery drive systems; in contrast, V-belts often face limitations with variable pulley designs because of their rigid cross-section and fixed grip profile. Optimizing drive efficiency in agricultural engineering favors flat belts when variable speed control and pulley variation are critical for equipment performance.

Flat belt vs V-belt for machinery drive systems Infographic

agridif.com

agridif.com