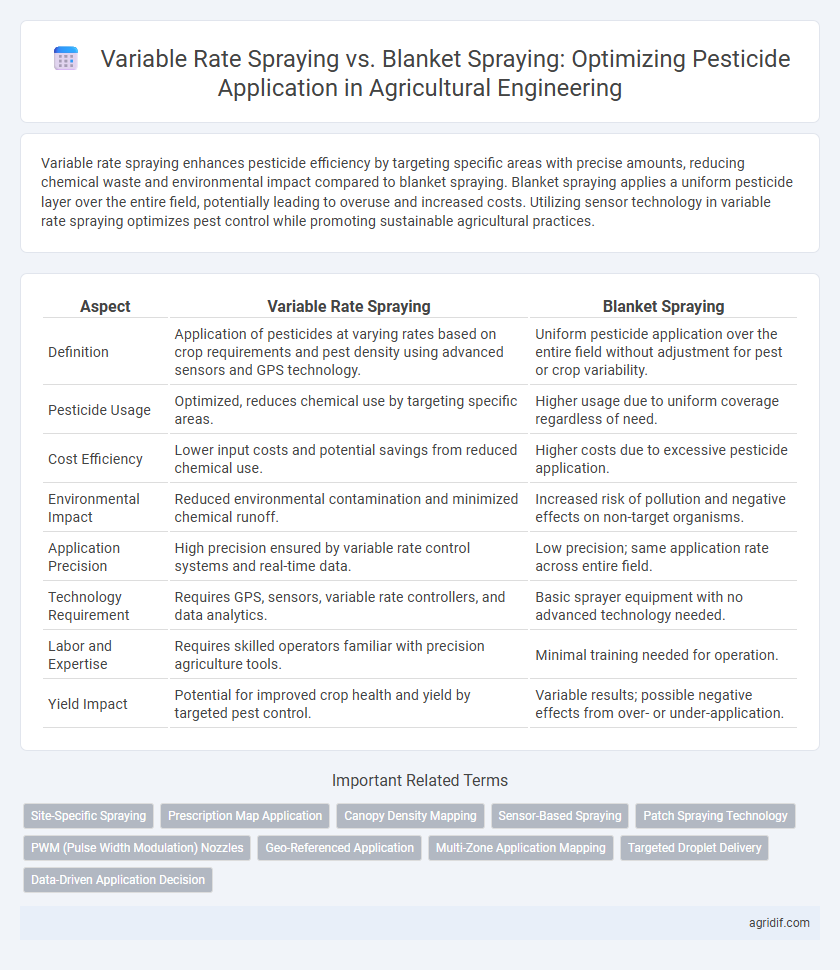

Variable rate spraying enhances pesticide efficiency by targeting specific areas with precise amounts, reducing chemical waste and environmental impact compared to blanket spraying. Blanket spraying applies a uniform pesticide layer over the entire field, potentially leading to overuse and increased costs. Utilizing sensor technology in variable rate spraying optimizes pest control while promoting sustainable agricultural practices.

Table of Comparison

| Aspect | Variable Rate Spraying | Blanket Spraying |

|---|---|---|

| Definition | Application of pesticides at varying rates based on crop requirements and pest density using advanced sensors and GPS technology. | Uniform pesticide application over the entire field without adjustment for pest or crop variability. |

| Pesticide Usage | Optimized, reduces chemical use by targeting specific areas. | Higher usage due to uniform coverage regardless of need. |

| Cost Efficiency | Lower input costs and potential savings from reduced chemical use. | Higher costs due to excessive pesticide application. |

| Environmental Impact | Reduced environmental contamination and minimized chemical runoff. | Increased risk of pollution and negative effects on non-target organisms. |

| Application Precision | High precision ensured by variable rate control systems and real-time data. | Low precision; same application rate across entire field. |

| Technology Requirement | Requires GPS, sensors, variable rate controllers, and data analytics. | Basic sprayer equipment with no advanced technology needed. |

| Labor and Expertise | Requires skilled operators familiar with precision agriculture tools. | Minimal training needed for operation. |

| Yield Impact | Potential for improved crop health and yield by targeted pest control. | Variable results; possible negative effects from over- or under-application. |

Introduction to Pesticide Application Methods

Variable rate spraying technology uses GPS and sensor data to adjust pesticide application rates precisely according to crop and pest variability, enhancing efficiency and reducing chemical waste. Blanket spraying applies a uniform pesticide dose across the entire field without considering spatial differences, leading to potential over-application or under-application in certain areas. Implementing variable rate spraying improves pest control accuracy, lowers environmental impact, and optimizes input costs compared to traditional blanket spraying methods.

Understanding Blanket Spraying in Agriculture

Blanket spraying in agriculture involves applying pesticides uniformly across an entire field regardless of pest density or crop variability, which can lead to over-application and increased chemical costs. This traditional method often results in environmental concerns such as pesticide runoff and resistance buildup in pests due to unnecessary exposure. Understanding blanket spraying highlights the need for more precise techniques like variable rate spraying that optimize pesticide use by targeting only affected areas, improving efficiency and sustainability.

What is Variable Rate Spraying?

Variable rate spraying in agricultural engineering is a precision pesticide application technique that adjusts the spray volume and chemical concentration based on real-time field data, crop health, and pest density. Unlike blanket spraying, which applies a uniform pesticide rate across the entire field, variable rate spraying optimizes input use, reduces chemical waste, and minimizes environmental impact. This technology integrates GPS mapping, sensors, and advanced software to deliver targeted pest control, enhancing crop productivity and sustainability.

Technology and Tools for Variable Rate Spraying

Variable rate spraying employs advanced sensors, GPS mapping, and automated control systems to adjust pesticide application precisely based on crop needs and field variability, enhancing efficiency over traditional blanket spraying methods. Technologies such as real-time vegetation indices, variable flow nozzles, and prescription maps enable targeted chemical usage, reducing waste and environmental impact. Integrating drones and AI-driven analytics further optimizes pesticide distribution by providing detailed spatial data and adaptive response during spraying operations.

Efficiency and Precision: Comparing Application Uniformity

Variable rate spraying enhances pesticide application efficiency by adjusting the spray volume based on real-time crop and pest variability, leading to improved precision and reduced chemical waste. Blanket spraying applies a uniform rate across the entire field, often resulting in over-application in low-need areas and under-application in high-need zones, compromising both efficacy and environmental safety. Studies demonstrate that variable rate technology achieves better application uniformity, optimizing pesticide use and minimizing negative impacts on non-target organisms.

Environmental Impact: Reducing Chemical Runoff

Variable rate spraying significantly minimizes chemical runoff by applying pesticides precisely where needed, reducing excess use and contamination of surrounding soil and water bodies. Blanket spraying distributes pesticides uniformly across fields, often leading to over-application and elevated environmental risks such as groundwater pollution and harm to non-target organisms. Precision agriculture technologies, including GPS and sensor data, enable variable rate spraying to enhance sustainability in pest management while protecting ecosystems.

Economic Considerations: Cost Savings and Input Use

Variable rate spraying significantly reduces input costs by applying pesticides only where needed, enhancing economic efficiency compared to blanket spraying's uniform application. Precise targeting minimizes chemical waste and lowers overall pesticide expenditure, contributing to substantial cost savings. Optimized input use also mitigates environmental impact, indirectly reducing compliance and remediation expenses associated with over-application.

Crop Health and Yield Benefits

Variable rate spraying in agricultural engineering enhances crop health by delivering precise pesticide amounts directly where needed, reducing chemical overuse and minimizing plant stress. This targeted approach improves overall yield by protecting crops more effectively from pests and diseases compared to uniform blanket spraying. Adoption of smart spraying technologies contributes to sustainable farming practices while maximizing crop productivity.

Challenges in Implementing Variable Rate Spraying

Variable rate spraying for pesticide application faces significant challenges including the high cost of advanced sensors and GPS technology required for precise input targeting. Variability in crop and pest data accuracy can lead to inconsistent application, reducing efficacy compared to traditional blanket spraying. Integration complexity with existing farm machinery and the need for operator training further hinder widespread adoption of variable rate spraying techniques.

Future Trends in Precision Pesticide Application

Variable rate spraying leverages GPS, AI, and sensor technology to apply pesticides only where needed, significantly reducing chemical use and environmental impact compared to traditional blanket spraying. Future trends emphasize integrating real-time data analytics and drone-based systems for adaptive, site-specific application, enhancing crop health monitoring and pest management efficiency. These advancements support sustainable agriculture by optimizing pesticide doses, reducing resistance development, and lowering operational costs.

Related Important Terms

Site-Specific Spraying

Variable rate spraying in agricultural engineering leverages GPS and sensor-based technology to apply pesticides precisely only where needed, reducing chemical use and environmental impact compared to traditional blanket spraying. Site-specific spraying enhances crop protection efficiency by tailoring pesticide dosage to varying field conditions, promoting sustainable pest management and optimizing input costs.

Prescription Map Application

Variable rate spraying utilizes prescription maps generated through GPS and remote sensing to apply pesticides precisely based on crop health and pest distribution, reducing chemical use and minimizing environmental impact. Blanket spraying applies uniform pesticide rates regardless of variability, often leading to over-application, higher costs, and increased risk of resistance development.

Canopy Density Mapping

Variable rate spraying leverages canopy density mapping through advanced sensors and drones to apply pesticides precisely according to plant density, optimizing chemical usage and reducing environmental impact. Blanket spraying disperses pesticides uniformly regardless of canopy variability, often leading to overuse in sparse areas and under-application in dense zones, resulting in inefficiencies and increased costs.

Sensor-Based Spraying

Sensor-based variable rate spraying enhances pesticide application efficiency by adjusting chemical loads in real-time according to crop density and pest presence, reducing overall pesticide usage and environmental impact. Unlike blanket spraying, which applies uniform rates regardless of field variability, sensor-based systems increase precision, improve crop health, and lower operational costs in agricultural engineering practices.

Patch Spraying Technology

Patch spraying technology in agricultural engineering enables precise pesticide application by targeting specific crop zones exhibiting pest infestations, significantly reducing chemical use compared to uniform blanket spraying methods. Variable rate spraying systems integrate real-time sensor data and GPS mapping to adjust spray volumes dynamically, enhancing environmental sustainability and crop health while minimizing input costs.

PWM (Pulse Width Modulation) Nozzles

Variable rate spraying using PWM (Pulse Width Modulation) nozzles enables precise control of pesticide application by modulating nozzle output without changing pressure, enhancing spray uniformity and reducing chemical waste compared to blanket spraying. PWM nozzles optimize droplet size and spray coverage based on real-time field variability data, improving pest management efficiency while minimizing environmental impact.

Geo-Referenced Application

Variable rate spraying leverages geo-referenced data to apply pesticides precisely based on spatial variability in crop conditions, optimizing chemical use and reducing environmental impact. Blanket spraying applies a uniform pesticide dose across an entire field, often leading to over-application in some areas and under-treatment in others, lacking the efficiency and environmental benefits of geo-referenced variable rate technology.

Multi-Zone Application Mapping

Variable rate spraying enhances efficiency by using multi-zone application mapping to adjust pesticide amounts precisely based on field variability, reducing chemical waste and environmental impact. Blanket spraying applies a uniform pesticide rate across the entire field, often leading to over-application in low-need areas and under-application in high-need zones, decreasing overall effectiveness.

Targeted Droplet Delivery

Variable rate spraying enhances targeted droplet delivery by adjusting pesticide application based on real-time crop and pest variability, reducing chemical waste and environmental impact compared to uniform blanket spraying. Precision in droplet size and distribution ensures optimal coverage on affected plant areas, improving pest control efficiency and crop health.

Data-Driven Application Decision

Variable rate spraying leverages real-time data from sensors, GPS, and crop health imagery to adjust pesticide application precisely, reducing chemical usage and environmental impact while enhancing pest control effectiveness. Blanket spraying applies a uniform pesticide rate across the entire field, often leading to over-application in some areas and under-treatment in others, resulting in inefficient resource use and potential resistance development.

Variable rate spraying vs blanket spraying for pesticide application Infographic

agridif.com

agridif.com