Laser leveling enhances field preparation by providing precise and uniform surface grading, reducing water wastage and improving irrigation efficiency compared to traditional leveling methods. Traditional leveling relies on manual or basic mechanical tools, often resulting in uneven surfaces that cause waterlogging and uneven crop growth. The accuracy of laser leveling leads to higher crop yields and resource conservation, making it a superior choice for modern agricultural engineering practices.

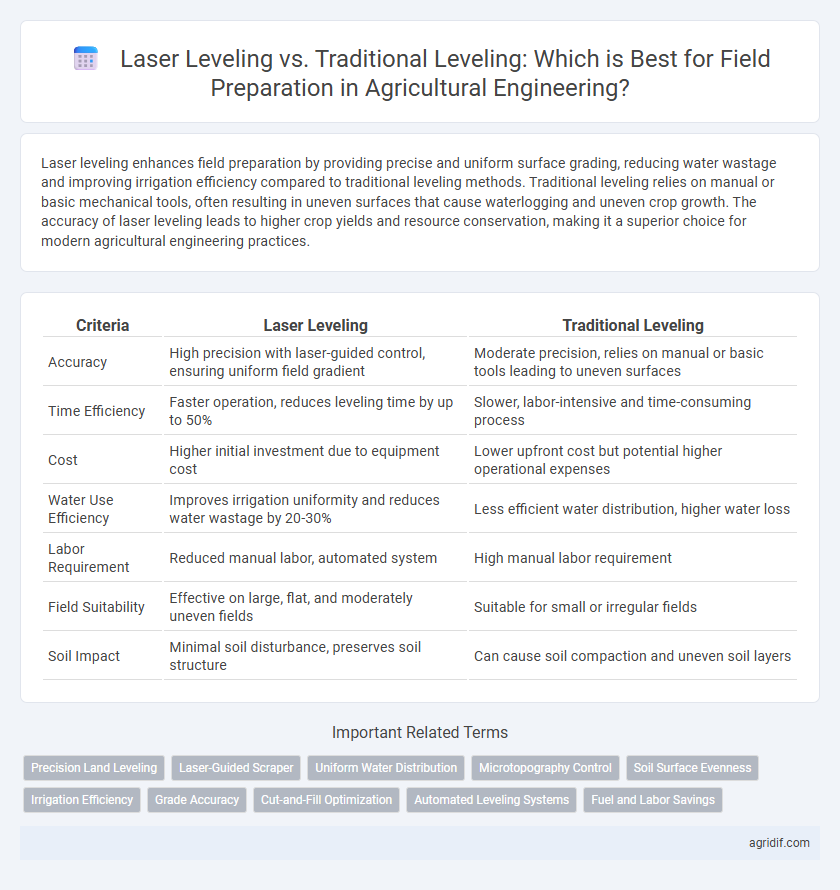

Table of Comparison

| Criteria | Laser Leveling | Traditional Leveling |

|---|---|---|

| Accuracy | High precision with laser-guided control, ensuring uniform field gradient | Moderate precision, relies on manual or basic tools leading to uneven surfaces |

| Time Efficiency | Faster operation, reduces leveling time by up to 50% | Slower, labor-intensive and time-consuming process |

| Cost | Higher initial investment due to equipment cost | Lower upfront cost but potential higher operational expenses |

| Water Use Efficiency | Improves irrigation uniformity and reduces water wastage by 20-30% | Less efficient water distribution, higher water loss |

| Labor Requirement | Reduced manual labor, automated system | High manual labor requirement |

| Field Suitability | Effective on large, flat, and moderately uneven fields | Suitable for small or irregular fields |

| Soil Impact | Minimal soil disturbance, preserves soil structure | Can cause soil compaction and uneven soil layers |

Introduction to Field Preparation Techniques

Laser leveling offers precise control over land grading, improving water distribution and minimizing runoff compared to traditional leveling methods that rely on manual or tractor-based equipment. This technology enhances field uniformity by achieving smoother and more consistent soil surface slopes, which supports optimal crop growth and reduces water wastage. Traditional leveling often results in uneven surfaces that can cause soil erosion and inefficient irrigation practices, limiting crop yield potential.

Overview of Traditional Land Leveling Methods

Traditional land leveling methods in agricultural engineering primarily involve manual or mechanical techniques such as plowing, harrowing, and grading using simple tools or bullock carts. These methods rely heavily on visual judgment and labor-intensive processes, often resulting in uneven field surfaces and suboptimal water distribution. Although cost-effective and widely accessible in rural areas, traditional leveling lacks the precision and efficiency offered by modern technologies like laser leveling.

Understanding Laser Land Leveling Technology

Laser land leveling technology uses precision laser beams to create uniformly flat fields, enhancing water efficiency and crop yield compared to traditional leveling methods. Traditional leveling relies on manual measurements and labor-intensive techniques, often resulting in uneven fields that cause waterlogging or drought stress. Implementing laser land leveling reduces input costs, improves irrigation efficiency by up to 30%, and promotes sustainable agricultural practices through precise field gradient control.

Accuracy Comparison: Laser vs Traditional Leveling

Laser leveling in agricultural engineering achieves precision within 0.5 cm, significantly surpassing the 3-5 cm accuracy range typical of traditional leveling methods. This heightened accuracy promotes uniform water distribution and optimal seed placement, directly enhancing crop yield and resource efficiency. The advanced technology in laser leveling reduces variability in field slope, making it a superior choice for precise field preparation.

Resource Efficiency and Water Savings

Laser leveling enhances resource efficiency by achieving uniform field surfaces, reducing water runoff and deep percolation compared to traditional leveling methods. This precision in land grading allows for optimal water distribution, leading to significant water savings of up to 30% in irrigation practices. Consequently, laser leveling supports sustainable agriculture through improved water use efficiency and reduced labor costs.

Impact on Crop Yield and Productivity

Laser leveling technology significantly improves field flatness and uniform water distribution, leading to enhanced crop yield and optimized water use efficiency compared to traditional leveling methods. Traditional leveling often results in uneven surfaces, causing waterlogging or drought stress that reduces productivity. Implementing laser leveling can boost crop yields by up to 20% through precise contour adjustment and reduced input wastage.

Cost Analysis: Investment and Long-Term Benefits

Laser leveling requires higher initial investment due to equipment costs, but it significantly reduces labor and water usage, translating into lower operational expenses over time. Traditional leveling demands less upfront capital but often leads to uneven fields, resulting in inefficient water distribution and increased input costs. Long-term benefits of laser leveling include improved crop yields and resource efficiency, justifying the initial expenditure through enhanced profitability and sustainability.

Time Requirements and Labor Involvement

Laser leveling technology significantly reduces time requirements for field preparation by offering precise, uniform leveling in a single pass compared to multiple passes needed in traditional leveling. Labor involvement is also minimized as laser systems operate with automated controls, reducing the manual effort required for measuring and adjusting field gradients. This efficiency leads to faster field readiness and optimized resource allocation in agricultural engineering projects.

Environmental Implications of Leveling Choices

Laser leveling significantly reduces water runoff and soil erosion compared to traditional leveling methods by creating a more uniform field surface that promotes efficient water distribution. Traditional leveling often results in uneven surfaces, increasing water wastage and nutrient loss, which can degrade soil health and contribute to environmental pollution. Adopting laser leveling enhances sustainable water management and supports conservation of soil structure in agricultural landscapes.

Choosing the Right Leveling Method for Your Farm

Laser leveling offers precise field grading with accuracy within millimeters, reducing water runoff and improving irrigation efficiency compared to traditional leveling methods, which rely on manual labor and simple tools like leveling rods and laser levels with less precision. Choosing the right leveling method depends on farm size, soil type, topography, and budget, where laser leveling suits large-scale farms requiring uniform slope for mechanized irrigation systems, while traditional leveling may be cost-effective for small or uneven plots. Evaluating crop types and water management practices ensures optimal investment in leveling technology to maximize yield and resource conservation.

Related Important Terms

Precision Land Leveling

Laser leveling enhances precision land leveling by using advanced laser-guided systems that ensure uniform flatness and optimal water distribution across fields, significantly reducing water wastage and improving crop yields. Traditional leveling methods rely on manual labor and basic tools, often resulting in uneven surfaces that hinder efficient irrigation and soil conservation.

Laser-Guided Scraper

Laser-guided scrapers offer precise field leveling by using laser technology to achieve uniform soil surface, enhancing water distribution and reducing runoff compared to traditional leveling methods that rely on manual or mechanical measurement techniques. This advanced technology improves irrigation efficiency and crop yield by minimizing soil compaction and ensuring optimal field gradient control across diverse agricultural terrains.

Uniform Water Distribution

Laser leveling technology ensures precise field leveling with accuracy up to 1-2 centimeters, promoting uniform water distribution and reducing water wastage by 20-30% compared to traditional leveling methods. Traditional leveling often results in uneven field surfaces that cause water pooling and inefficient irrigation, leading to reduced crop yields and increased labor costs.

Microtopography Control

Laser leveling offers precise microtopography control by ensuring uniform field gradients that enhance water distribution and reduce runoff in agricultural plots, outperforming traditional leveling methods reliant on manual or optical tools. This advanced technology enables consistent soil surface elevation with accuracy up to +-2 mm, leading to improved crop uniformity and irrigation efficiency compared to traditional leveling techniques with higher variability.

Soil Surface Evenness

Laser leveling technology achieves significantly higher soil surface evenness compared to traditional leveling methods, reducing surface irregularities to less than 0.5 centimeters. This precision enhances water distribution efficiency and promotes uniform crop growth, directly improving agricultural productivity and conserving resources.

Irrigation Efficiency

Laser leveling enhances irrigation efficiency by ensuring uniform water distribution, minimizing water wastage, and reducing runoff compared to traditional leveling methods that often result in uneven field surfaces and poor water management. This precision technology improves crop yield and conserves water resources by optimizing the field slope to ideal levels within millimeter accuracy.

Grade Accuracy

Laser leveling achieves grade accuracy within +-0.5 cm, significantly outperforming traditional leveling methods that typically have an accuracy of +-2-5 cm. This enhanced precision ensures uniform water distribution and optimal crop growth, leading to increased agricultural productivity and resource efficiency.

Cut-and-Fill Optimization

Laser leveling technology significantly enhances cut-and-fill optimization in field preparation by providing precise, uniform surface gradients that minimize soil displacement and water runoff. Traditional leveling methods often result in uneven fields with excessive cut-and-fill volumes, leading to inefficient water management and increased labor costs.

Automated Leveling Systems

Automated Laser Leveling Systems offer precise field leveling with an accuracy of +-2 mm, significantly reducing water usage by up to 30% compared to traditional leveling methods. These systems enhance crop uniformity, minimize soil erosion, and accelerate field preparation time, leading to higher agricultural productivity and sustainability.

Fuel and Labor Savings

Laser leveling reduces fuel consumption by enabling precise, uniform field leveling, minimizing tractor passes compared to traditional methods. This technology decreases labor hours by automating measurement and adjustment processes, resulting in faster field preparation and lower operational costs.

Laser leveling vs traditional leveling for field preparation Infographic

agridif.com

agridif.com