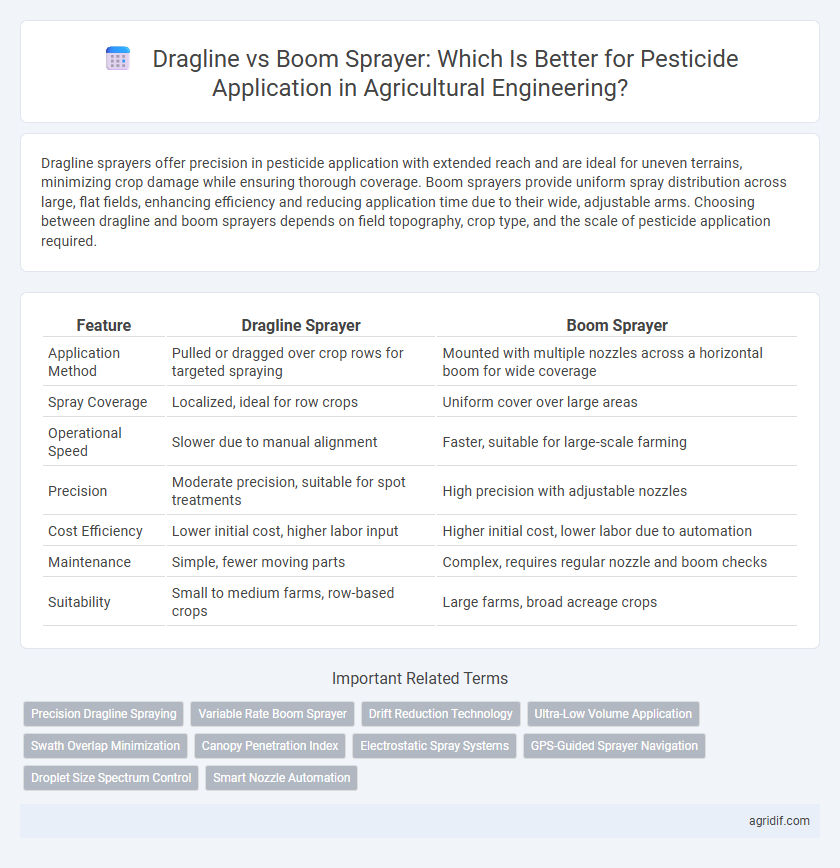

Dragline sprayers offer precision in pesticide application with extended reach and are ideal for uneven terrains, minimizing crop damage while ensuring thorough coverage. Boom sprayers provide uniform spray distribution across large, flat fields, enhancing efficiency and reducing application time due to their wide, adjustable arms. Choosing between dragline and boom sprayers depends on field topography, crop type, and the scale of pesticide application required.

Table of Comparison

| Feature | Dragline Sprayer | Boom Sprayer |

|---|---|---|

| Application Method | Pulled or dragged over crop rows for targeted spraying | Mounted with multiple nozzles across a horizontal boom for wide coverage |

| Spray Coverage | Localized, ideal for row crops | Uniform cover over large areas |

| Operational Speed | Slower due to manual alignment | Faster, suitable for large-scale farming |

| Precision | Moderate precision, suitable for spot treatments | High precision with adjustable nozzles |

| Cost Efficiency | Lower initial cost, higher labor input | Higher initial cost, lower labor due to automation |

| Maintenance | Simple, fewer moving parts | Complex, requires regular nozzle and boom checks |

| Suitability | Small to medium farms, row-based crops | Large farms, broad acreage crops |

Introduction to Pesticide Application Methods in Agriculture

Dragline sprayers offer extensive reach and are suitable for large-scale pesticide application on uneven terrain, using hydraulic systems to distribute chemicals effectively. Boom sprayers provide precise, uniform coverage with adjustable nozzles mounted on a horizontal boom, making them ideal for row crops and flat fields. Selecting the appropriate sprayer depends on field size, crop type, and terrain to optimize pesticide efficiency and reduce environmental impact.

Overview of Dragline Sprayer Technology

Dragline sprayer technology employs a suspended boom system that enables precise pesticide application over extensive crop areas with minimal soil compaction and enhanced operator visibility. The advanced hydraulic control and adjustable nozzle spacing optimize spray patterns, ensuring uniform coverage and reducing chemical waste. This technology is particularly effective in uneven terrains, providing flexibility and efficiency compared to traditional boom sprayers.

Key Features of Boom Sprayer Systems

Boom sprayer systems feature adjustable nozzles for uniform pesticide distribution and extendable arms that cover large field areas efficiently. Their precise pressure control ensures optimal droplet size, reducing chemical waste and environmental impact. Integrated GPS technology in modern boom sprayers enhances application accuracy and supports variable rate spraying based on crop needs.

Comparative Efficiency: Dragline vs Boom Sprayers

Dragline sprayers offer greater maneuverability in uneven terrains compared to boom sprayers, enhancing pesticide application efficiency in hilly or irregular fields. Boom sprayers provide uniform pesticide distribution over large, flat areas with higher coverage capacity and adjustable nozzle configurations. Efficiency in pesticide application depends on field topography, crop type, and desired spray precision, where draglines excel in targeted spraying while booms optimize volume coverage.

Coverage Uniformity and Spray Penetration

Dragline sprayers offer superior coverage uniformity due to their precise boom height control and consistent nozzle spacing, ensuring even pesticide distribution across large fields. Boom sprayers provide enhanced spray penetration through adjustable nozzle angles and higher operating pressures, facilitating better reach into dense crop canopies. Optimizing coverage uniformity and spray penetration depends on crop type and field topography, with dragline sprayers favoring flat terrains and boom sprayers excelling in varied canopy structures.

Pesticide Drift Potential and Environmental Impact

Dragline sprayers exhibit higher pesticide drift potential due to their elevated spray height and greater droplet exposure to wind, increasing environmental contamination risks in surrounding ecosystems. Boom sprayers, with adjustable low-height nozzles and uniform application patterns, minimize drift and reduce off-target chemical dispersion, enhancing environmental safety. Selecting boom sprayers over dragline systems significantly mitigates pesticide drift impact, preserving soil and water quality in agricultural landscapes.

Suitability for Different Crop Types and Field Sizes

Dragline sprayers excel in large-scale, flat fields with row crops such as corn and wheat, providing high-capacity pesticide application with minimal operator intervention. Boom sprayers offer superior precision and maneuverability, making them ideal for smaller, irregularly shaped fields and diverse crop types like vegetables and orchards where targeted pesticide delivery reduces chemical use. Field size and crop architecture significantly influence the choice, with draglines suited for expansive monocultures and boom sprayers preferred for heterogeneous cropping systems.

Operational Costs and Maintenance Requirements

Dragline sprayers typically incur higher operational costs due to greater fuel consumption and more frequent maintenance stemming from their complex mechanical parts. Boom sprayers offer lower maintenance requirements, characterized by simpler designs and efficient nozzle systems that minimize downtime and repair expenses. Choosing boom sprayers can lead to cost savings by reducing the frequency of part replacements and streamlining operational workflows in pesticide application.

Safety Considerations for Operators

Dragline sprayers offer greater operator safety by maintaining a longer distance from pesticide clouds, reducing inhalation risks compared to boom sprayers. Boom sprayers demand stringent protective gear due to closer proximity to chemical spray and increased exposure through drift and splash. Effective ventilation, sealed cabins, and automatic shut-off systems enhance safety in both types, but the extended reach of dragline sprayers significantly minimizes direct operator contact with hazardous pesticides.

Conclusion: Selecting the Optimal Sprayer for Agricultural Needs

Dragline sprayers offer precise pesticide application and are ideal for large-scale fields requiring uniform coverage, while boom sprayers provide versatility and efficiency across varied crop types and field shapes. Choosing between the two depends on factors like field size, crop type, terrain, and pesticide volume to optimize application effectiveness and minimize chemical waste. Integrating sprayer technology with specific agricultural practices enhances pest control outcomes and supports sustainable farming.

Related Important Terms

Precision Dragline Spraying

Precision Dragline Spraying in agricultural engineering offers enhanced pesticide application by utilizing a high-reach mechanical arm that delivers uniform coverage over tall crops, reducing drift and chemical waste compared to traditional Boom sprayers. This method improves spray accuracy and efficiency on uneven terrain, making it ideal for orchards and large-scale plantations where precise targeting is critical for crop health and environmental safety.

Variable Rate Boom Sprayer

Variable Rate Boom Sprayers use precise GPS and sensor technology to adjust pesticide application rates in real time, enhancing coverage efficiency and reducing chemical waste compared to Dragline sprayers. This technology optimizes input usage by targeting specific crop zones, improving pest control accuracy and promoting sustainable agricultural practices.

Drift Reduction Technology

Dragline sprayers with Drift Reduction Technology (DRT) utilize low-pressure nozzles and angled spray patterns to minimize pesticide drift, enhancing targeted application and reducing environmental contamination. Boom sprayers equipped with advanced air-assist systems and shielded nozzles offer precise coverage and improved spray deposition control, significantly lowering off-target drift compared to conventional methods.

Ultra-Low Volume Application

Dragline sprayers excel in ultra-low volume pesticide application by delivering precise droplet sizes with minimal drift, making them highly efficient for large-scale, uniform coverage in agricultural fields. Boom sprayers offer adjustable nozzle configurations and variable pressure control, enabling targeted spraying with flexibility across different crop types, but may require higher spray volumes compared to the dragline for achieving similar ultra-low volume effectiveness.

Swath Overlap Minimization

Dragline sprayers typically offer greater control in swath overlap minimization due to their flexible boom heights and adjustable spray widths, reducing pesticide waste and environmental impact. Boom sprayers, while efficient for uniform coverage, often require precise calibration to avoid excessive overlap, which can lead to increased chemical use and higher operational costs.

Canopy Penetration Index

Dragline sprayers exhibit a higher Canopy Penetration Index compared to Boom sprayers, enabling more effective pesticide distribution within dense crop canopies. This enhanced penetration reduces pesticide runoff and ensures targeted application, improving both efficiency and environmental sustainability in agricultural practices.

Electrostatic Spray Systems

Electrostatic spray systems integrated into dragline and boom sprayers enhance pesticide application efficiency by electrically charging droplets, improving adhesion to crop surfaces and reducing drift. Dragline sprayers offer precise targeting in uneven terrain, while boom sprayers provide uniform coverage over large fields, both benefiting from electrostatic technology to optimize pesticide distribution and minimize environmental impact.

GPS-Guided Sprayer Navigation

GPS-guided sprayer navigation enhances precision in pesticide application by enabling dragline sprayers to efficiently cover extensive fields with reduced overlap, whereas boom sprayers benefit from GPS technology by optimizing spray patterns for uniform coverage and minimizing chemical waste. Integrating GPS systems with both dragline and boom sprayers improves field mapping accuracy and application consistency, leading to increased operational efficiency and environmental sustainability in agricultural engineering.

Droplet Size Spectrum Control

Dragline sprayers offer limited droplet size spectrum control due to their fixed nozzle positions, resulting in less precise pesticide application compared to boom sprayers. Boom sprayers allow for adjustable nozzle types and pressures, enabling optimized droplet size distribution for targeted coverage and reduced pesticide drift.

Smart Nozzle Automation

Smart nozzle automation in dragline sprayers enhances precision pesticide application through controlled droplet size and targeted spray patterns, minimizing chemical waste and environmental impact. Boom sprayers with advanced smart nozzles enable uniform pesticide distribution over large crop areas, utilizing GPS and real-time sensor data to adjust spray rates dynamically for improved efficiency and reduced runoff.

Dragline vs Boom sprayer for pesticide application Infographic

agridif.com

agridif.com