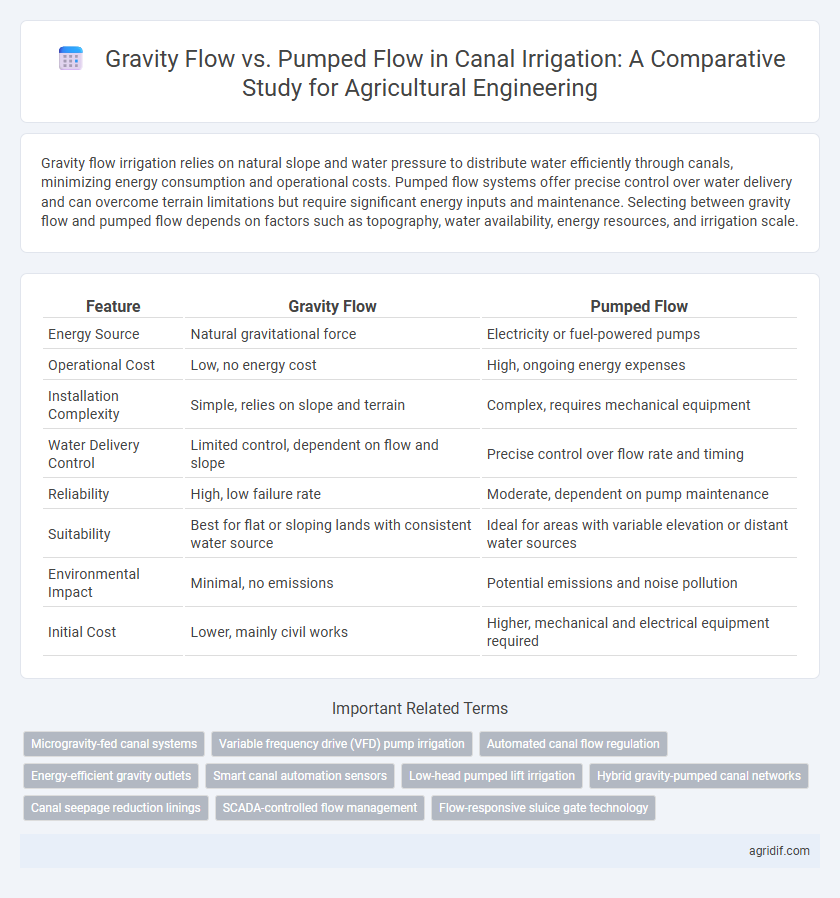

Gravity flow irrigation relies on natural slope and water pressure to distribute water efficiently through canals, minimizing energy consumption and operational costs. Pumped flow systems offer precise control over water delivery and can overcome terrain limitations but require significant energy inputs and maintenance. Selecting between gravity flow and pumped flow depends on factors such as topography, water availability, energy resources, and irrigation scale.

Table of Comparison

| Feature | Gravity Flow | Pumped Flow |

|---|---|---|

| Energy Source | Natural gravitational force | Electricity or fuel-powered pumps |

| Operational Cost | Low, no energy cost | High, ongoing energy expenses |

| Installation Complexity | Simple, relies on slope and terrain | Complex, requires mechanical equipment |

| Water Delivery Control | Limited control, dependent on flow and slope | Precise control over flow rate and timing |

| Reliability | High, low failure rate | Moderate, dependent on pump maintenance |

| Suitability | Best for flat or sloping lands with consistent water source | Ideal for areas with variable elevation or distant water sources |

| Environmental Impact | Minimal, no emissions | Potential emissions and noise pollution |

| Initial Cost | Lower, mainly civil works | Higher, mechanical and electrical equipment required |

Introduction to Canal Irrigation Methods

Gravity flow canal irrigation relies on natural land slope to distribute water, minimizing energy consumption and operational costs, making it ideal for regions with suitable topography. Pumped flow systems use mechanical pumps to lift and convey water, offering greater control over water delivery in flat or uneven terrains where gravity alone is insufficient. Selecting between gravity and pumped flow methods depends on site-specific factors such as land gradient, water availability, and economic considerations.

Overview of Gravity Flow Irrigation

Gravity flow irrigation utilizes the natural slope of the land to channel water through canals, minimizing energy consumption and operational costs. This method ensures uniform distribution of water by relying on gravitational force, making it highly efficient for large-scale agricultural fields with suitable topography. The design of gravity flow systems emphasizes proper gradient management and lining to reduce seepage and enhance water delivery efficiency.

Overview of Pumped Flow Irrigation

Pumped flow irrigation uses mechanical pumps to transport water from sources such as rivers, reservoirs, or wells into canal systems, providing precise control over flow rates and irrigation schedules. This method enables efficient water distribution in areas with uneven terrain or where gravity flow is impractical, increasing water use efficiency and crop yield. Pumped flow systems require initial investment in pump technology and energy resources, but offer flexibility and reliability for modern agricultural engineering.

Key Components of Gravity Flow Systems

Gravity flow irrigation systems rely on key components such as leveled canals, headworks for water diversion, and control structures like gates and weirs to regulate water distribution. The design leverages natural land gradients to move water without mechanical energy, emphasizing efficient channel lining to minimize seepage losses. These components collectively ensure sustainable and cost-effective water delivery in canal irrigation networks.

Essential Elements of Pumped Flow Systems

Pumped flow systems in canal irrigation rely on mechanical pumps to elevate and distribute water, enabling precise control over flow rates and timing. Essential elements include centrifugal or axial-flow pumps, motor drives, intake structures, and control valves, all designed to optimize energy efficiency and water delivery. These components ensure consistent water pressure and adaptability to varying topographies, improving irrigation reliability compared to gravity flow systems.

Comparative Water Distribution Efficiency

Gravity flow irrigation systems typically achieve higher water distribution efficiency by minimizing energy consumption and utilizing natural land gradients to deliver water uniformly across canal networks. Pumped flow systems, while offering greater control and flexibility, often exhibit lower overall efficiency due to energy losses and variations in pressure that can cause uneven water distribution. Comparative analyses indicate gravity flow can surpass 80% efficiency in ideal terrain conditions, whereas pumped systems commonly operate between 60-75% efficiency depending on pump performance and maintenance.

Energy Requirements: Gravity vs Pumped Flow

Gravity flow irrigation utilizes the natural slope of the land to move water through canals, requiring minimal energy input beyond initial canal construction and maintenance. Pumped flow irrigation relies on mechanical pumps to lift and transport water, resulting in significantly higher energy consumption depending on pump size, water volume, and lift height. Energy efficiency in gravity systems leads to lower operational costs and reduced carbon footprint compared to the continuous electricity or fuel demands in pumped flow systems.

Cost Analysis and Economic Considerations

Gravity flow irrigation systems typically incur lower operational costs due to the absence of energy expenses, making them economically favorable in regions with suitable topography and water availability. Pumped flow systems involve higher initial capital investment and ongoing energy costs, but they provide greater control over water delivery and can be viable in flat or uneven terrains where gravity flow is impractical. Economic considerations include evaluating the lifecycle costs, energy prices, maintenance expenses, and crop water requirements to determine the most cost-effective irrigation method for a given agricultural project.

Environmental Impacts of Both Systems

Gravity flow irrigation systems reduce energy consumption by relying on natural water gradients, minimizing carbon emissions compared to pumped flow systems that depend on fossil fuels or electricity. However, gravity flow may cause waterlogging and soil erosion if not properly managed, leading to habitat disruption and nutrient runoff. Pumped flow systems offer controlled water distribution, reducing water wastage and potentially lowering salinity levels, but their reliance on mechanical power increases greenhouse gas emissions and ecological footprint.

Suitability and Recommendations for Different Terrains

Gravity flow irrigation suits flat or gently sloping terrains by leveraging natural slope to distribute water efficiently with minimal energy input and reduced operational costs. Pumped flow systems are recommended for uneven or steep terrains where gravity cannot provide adequate water pressure, allowing precise control over flow rates and irrigation scheduling. Combining terrain analysis with water availability helps determine the most effective irrigation method to optimize water use and crop yields.

Related Important Terms

Microgravity-fed canal systems

Microgravity-fed canal systems rely on natural terrain slopes to deliver water efficiently without mechanical inputs, minimizing operational costs and energy consumption. This gravity flow method enhances sustainable irrigation by reducing maintenance needs and promoting uniform water distribution compared to pumped flow systems, which depend on continuous energy supply and higher infrastructure investment.

Variable frequency drive (VFD) pump irrigation

Variable frequency drive (VFD) pump irrigation enhances pumped flow efficiency by precisely controlling pump speeds, reducing energy consumption compared to traditional gravity flow systems. VFD technology optimizes water delivery in canal irrigation, providing adjustable flow rates that accommodate varying crop water requirements and minimize hydraulic losses.

Automated canal flow regulation

Automated canal flow regulation leverages gravity flow's energy efficiency and low operational costs by using smart gates and sensors for precise water distribution in irrigation canals. Pumped flow systems integrate sensors and variable-speed pumps for responsive water delivery, optimizing flow control but increasing energy consumption and maintenance complexity.

Energy-efficient gravity outlets

Energy-efficient gravity outlets in canal irrigation utilize natural gravitational forces to distribute water, minimizing reliance on powered pumps and significantly reducing energy consumption. These systems optimize water delivery through precise channel design and control structures, enhancing sustainability and lowering operational costs compared to pumped flow alternatives.

Smart canal automation sensors

Gravity flow irrigation relies on natural water gradients to distribute water through canals, reducing energy consumption but often causing inconsistent flow rates; smart canal automation sensors enhance this system by continuously monitoring water levels and flow velocity to optimize distribution efficiency. Pumped flow systems, while energy-intensive, offer precise control over water delivery, and when integrated with intelligent sensors for real-time pressure and sediment detection, they enable adaptive management to maximize irrigation uniformity and minimize water waste.

Low-head pumped lift irrigation

Low-head pumped lift irrigation optimizes water delivery efficiency in canal irrigation by reducing energy consumption compared to traditional high-head systems, making it ideal for terrains with minimal elevation differences. Its integration allows precise water control, minimizes wastage, and supports sustainable agricultural water management in low-gradient areas.

Hybrid gravity-pumped canal networks

Hybrid gravity-pumped canal networks leverage gravity flow for primary water conveyance and use pumps strategically to overcome elevation challenges and improve water distribution efficiency in canal irrigation systems. Integrating energy-efficient pumps reduces operational costs while maintaining sustainable water delivery, optimizing irrigation scheduling and enhancing crop yield in regions with variable topography.

Canal seepage reduction linings

Canal seepage reduction linings significantly enhance water efficiency in gravity flow irrigation by minimizing water loss through infiltration, whereas pumped flow systems rely more on energy-intensive methods to deliver water, potentially increasing operational costs. Implementing impermeable linings like concrete or geomembranes in gravity flow canals not only preserves soil moisture but also improves water delivery uniformity and reduces the need for frequent downstream pumping.

SCADA-controlled flow management

SCADA-controlled gravity flow systems in canal irrigation optimize water delivery by leveraging natural topography, reducing energy consumption and operational costs compared to pumped flow methods. Pumped flow systems integrated with SCADA allow precise pressure regulation and real-time monitoring, enhancing irrigation efficiency and flexibility in terrains lacking sufficient gravity gradient.

Flow-responsive sluice gate technology

Gravity flow irrigation relies on natural water gradients, reducing energy consumption but facing challenges in precise water delivery, while pumped flow systems offer controlled, consistent pressure suitable for varied topographies. Flow-responsive sluice gate technology enhances gravity flow efficiency by dynamically adjusting gate positions to optimize water distribution, minimize wastage, and maintain uniform canal discharge rates.

Gravity Flow vs Pumped Flow for Canal Irrigation Infographic

agridif.com

agridif.com