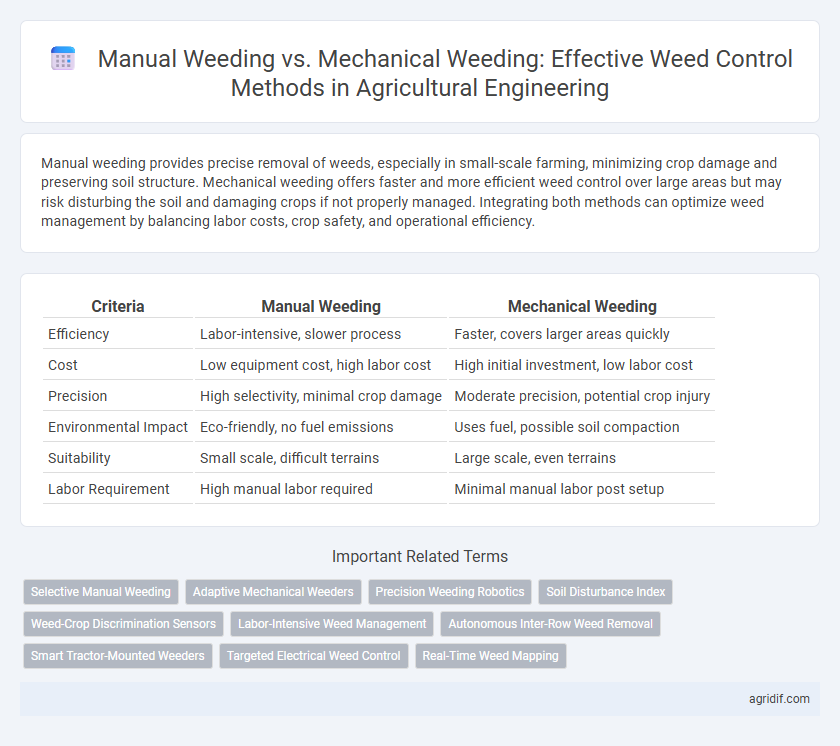

Manual weeding provides precise removal of weeds, especially in small-scale farming, minimizing crop damage and preserving soil structure. Mechanical weeding offers faster and more efficient weed control over large areas but may risk disturbing the soil and damaging crops if not properly managed. Integrating both methods can optimize weed management by balancing labor costs, crop safety, and operational efficiency.

Table of Comparison

| Criteria | Manual Weeding | Mechanical Weeding |

|---|---|---|

| Efficiency | Labor-intensive, slower process | Faster, covers larger areas quickly |

| Cost | Low equipment cost, high labor cost | High initial investment, low labor cost |

| Precision | High selectivity, minimal crop damage | Moderate precision, potential crop injury |

| Environmental Impact | Eco-friendly, no fuel emissions | Uses fuel, possible soil compaction |

| Suitability | Small scale, difficult terrains | Large scale, even terrains |

| Labor Requirement | High manual labor required | Minimal manual labor post setup |

Introduction to Weed Control in Agriculture

Weed control in agriculture is essential for optimizing crop yield and maintaining soil health. Manual weeding involves hand removal of weeds, providing precise control but requiring significant labor and time. Mechanical weeding utilizes machinery such as cultivators and hoeing devices, offering faster and more scalable weed management while minimizing soil disturbance.

Overview of Manual Weeding Methods

Manual weeding methods in agricultural engineering involve the use of handheld tools such as hoes, hand pullers, and knives to physically remove weeds from crop fields, ensuring minimal soil disturbance and precise control around plants. These techniques are labor-intensive but provide flexibility for small-scale farms and organic agriculture, where chemical herbicides are restricted. Emphasizing ergonomic tool design and efficient weed removal strategies enhances productivity and reduces operator fatigue during manual weeding operations.

Overview of Mechanical Weeding Techniques

Mechanical weeding techniques in agricultural engineering utilize machinery such as rotary hoes, tine weeders, and inter-row cultivators to efficiently remove weeds while minimizing soil disturbance. These methods enhance productivity by covering larger areas quickly compared to manual weeding and reduce labor costs significantly. Advanced mechanical weeders integrate GPS and sensor technologies for precision targeting, improving weed control efficacy and crop protection.

Efficiency of Manual vs Mechanical Weeding

Manual weeding offers precise control and is highly effective for small-scale farms or delicate crops but is labor-intensive and time-consuming, limiting efficiency on larger fields. Mechanical weeding, using equipment like rotary hoes and cultivators, significantly increases efficiency by covering extensive areas rapidly, reducing labor costs and time. However, mechanical methods might cause soil disturbance and are less precise, potentially impacting crop health compared to manual weeding.

Labor Requirements and Costs Comparison

Manual weeding demands extensive labor input, often leading to higher labor costs and slower field coverage compared to mechanical weeding. Mechanical weeding significantly reduces labor requirements by using machines that can cover large areas quickly, resulting in lower operational costs over time despite higher initial investment. Efficient mechanical weed control enhances productivity in large-scale farming by minimizing labor dependency and reducing overall weed management expenses.

Impact on Crop Yield and Quality

Manual weeding provides precise removal of weeds, minimizing crop damage and preserving yield quality but is labor-intensive and less feasible for large-scale farming. Mechanical weeding increases efficiency in removing weeds across extensive fields, though it may cause soil disturbance and crop injury, potentially reducing overall crop yield and quality. Optimizing weed control strategies involves balancing labor costs and machinery impacts to enhance crop productivity and maintain quality standards.

Environmental Implications of Weeding Methods

Manual weeding minimizes soil disturbance and reduces energy consumption, leading to a lower carbon footprint compared to mechanical weeding. Mechanical weeding often involves fuel-powered machinery that emits greenhouse gases and can cause soil compaction, negatively affecting soil health and biodiversity. Prioritizing manual weeding supports sustainable agriculture by preserving soil structure and promoting ecological balance in crop production.

Suitability for Different Crop Types and Scales

Manual weeding is highly suitable for small-scale farms and crops with delicate root systems, such as vegetables and horticultural plants, where precision and minimal soil disturbance are critical. Mechanical weeding is more efficient for large-scale cereal and row crops like maize, wheat, and soybeans, offering faster weed control with reduced labor costs. Selection depends on crop sensitivity, farm size, and cost-effectiveness, with manual methods favored for diverse or uneven fields and mechanical for uniform, high-volume cultivation.

Challenges and Limitations of Each Approach

Manual weeding in agricultural engineering faces challenges such as high labor costs, slow process speed, and increased physical strain on workers, limiting its scalability for large farms. Mechanical weeding encounters difficulties with soil compaction, machinery costs, and inefficiencies in distinguishing between crops and weeds, leading to potential crop damage and increased maintenance demands. Both approaches struggle with achieving precise weed control while balancing economic and environmental sustainability.

Future Trends in Weed Control Technology

Future trends in weed control technology emphasize the integration of precision agriculture with advanced robotics and AI-driven systems to enhance efficiency and reduce labor costs in mechanical weeding. Innovations such as autonomous weeders equipped with machine learning algorithms enable real-time weed identification and targeted removal, surpassing the limitations of manual weeding. Sustainable practices are promoted through sensor-based weed detection, minimizing herbicide use and fostering environmentally friendly crop management.

Related Important Terms

Selective Manual Weeding

Selective manual weeding offers precise removal of unwanted weeds without damaging crops, enhancing crop health and yield in sensitive agricultural systems. Compared to mechanical weeding, it minimizes soil disturbance and preserves beneficial soil microorganisms critical for sustainable farming practices.

Adaptive Mechanical Weeders

Adaptive mechanical weeders utilize sensor-based technologies and AI algorithms to distinguish between crops and weeds, enabling precise targeting that minimizes crop damage and reduces labor costs. These machines enhance weed control efficiency by adjusting operation parameters in real-time based on field conditions, leading to increased crop yield and sustainable farming practices.

Precision Weeding Robotics

Precision weeding robotics enhances mechanical weeding by using advanced sensors and AI algorithms to identify and target specific weed species, minimizing crop damage and reducing herbicide usage. This technology offers higher efficiency and sustainability compared to manual weeding, significantly lowering labor costs and increasing productivity in large-scale agricultural operations.

Soil Disturbance Index

Manual weeding results in a lower Soil Disturbance Index (SDI) compared to mechanical weeding, preserving soil structure and reducing erosion risks. Mechanical weeding, while efficient for large-scale operations, significantly increases the SDI, leading to greater soil compaction and disruption of beneficial microbial communities essential for crop health.

Weed-Crop Discrimination Sensors

Weed-crop discrimination sensors enhance mechanical weeding by accurately identifying and targeting weeds, reducing crop damage and improving efficiency compared to manual weeding methods. Advanced sensor technologies such as near-infrared spectroscopy and machine vision enable real-time differentiation between crops and weeds, optimizing herbicide application and minimizing labor costs in precision agriculture.

Labor-Intensive Weed Management

Manual weeding demands significant labor input, often requiring 30-50 hours per hectare, making it suitable for small-scale farms with accessible labor resources. Mechanical weeding reduces physical strain and increases efficiency, processing up to 4 hectares per day, but involves higher initial equipment costs and maintenance.

Autonomous Inter-Row Weed Removal

Autonomous inter-row weed removal systems use precision robotics and advanced sensors to target weeds between crop rows, significantly reducing labor costs and minimizing crop damage compared to manual weeding. These AI-driven machines enhance efficiency and sustainability by optimizing herbicide application and enabling timely weed control, promoting higher crop yields in agricultural engineering practices.

Smart Tractor-Mounted Weeders

Smart tractor-mounted weeders leverage GPS technology and advanced sensors to precisely target weed-infested areas, increasing efficiency compared to traditional manual weeding. These automated systems reduce labor costs and soil compaction while enabling faster, more consistent weed control across large agricultural fields.

Targeted Electrical Weed Control

Targeted electrical weed control offers a precise and energy-efficient alternative to manual weeding and mechanical weeding by using electric currents to disrupt weed growth at the cellular level without damaging crops. This technology enhances sustainability in agricultural engineering by reducing chemical herbicide use and minimizing soil disturbance compared to conventional mechanical methods.

Real-Time Weed Mapping

Real-time weed mapping enhances the precision of mechanical weeding by using GPS-guided sensors to identify and target weed infestations, reducing crop damage and labor costs compared to manual weeding. Integrating real-time data with automated machinery improves efficiency and fosters sustainable weed management in large-scale agricultural operations.

Manual Weeding vs Mechanical Weeding for Weed Control Infographic

agridif.com

agridif.com