HDPE pipes offer superior flexibility, durability, and resistance to chemical corrosion compared to PVC pipes, making them ideal for varied irrigation systems exposed to harsh environmental conditions. PVC pipes, while cost-effective and easier to install due to their rigid structure, may be prone to cracking under high-pressure or extreme temperature fluctuations. Choosing HDPE pipes enhances the longevity and efficiency of irrigation infrastructure, reducing maintenance costs and water loss from leaks.

Table of Comparison

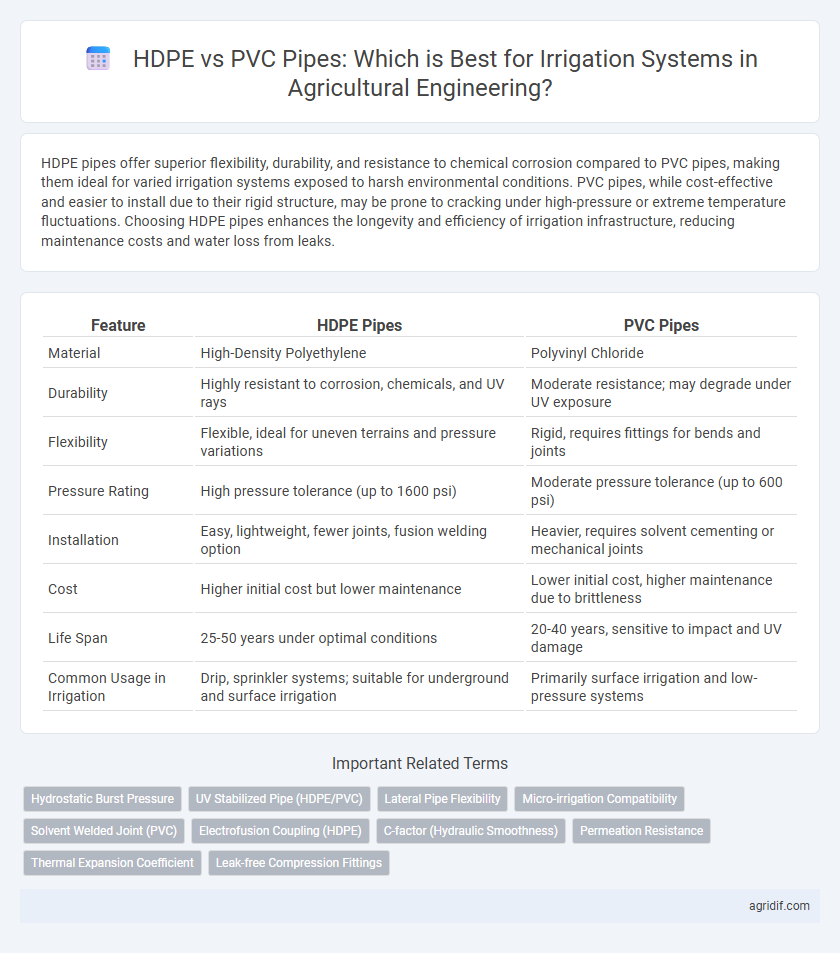

| Feature | HDPE Pipes | PVC Pipes |

|---|---|---|

| Material | High-Density Polyethylene | Polyvinyl Chloride |

| Durability | Highly resistant to corrosion, chemicals, and UV rays | Moderate resistance; may degrade under UV exposure |

| Flexibility | Flexible, ideal for uneven terrains and pressure variations | Rigid, requires fittings for bends and joints |

| Pressure Rating | High pressure tolerance (up to 1600 psi) | Moderate pressure tolerance (up to 600 psi) |

| Installation | Easy, lightweight, fewer joints, fusion welding option | Heavier, requires solvent cementing or mechanical joints |

| Cost | Higher initial cost but lower maintenance | Lower initial cost, higher maintenance due to brittleness |

| Life Span | 25-50 years under optimal conditions | 20-40 years, sensitive to impact and UV damage |

| Common Usage in Irrigation | Drip, sprinkler systems; suitable for underground and surface irrigation | Primarily surface irrigation and low-pressure systems |

Introduction to Irrigation Pipe Materials

HDPE pipes and PVC pipes are the two primary materials used in irrigation systems, each offering distinct advantages based on their physical and chemical properties. HDPE pipes provide superior flexibility, chemical resistance, and durability under high pressure, making them ideal for uneven terrains and long-term use. PVC pipes, characterized by their rigidity, cost-effectiveness, and ease of installation, are commonly chosen for fixed irrigation layouts with relatively stable ground conditions.

Overview of HDPE and PVC Pipes

HDPE pipes, made from high-density polyethylene, offer superior flexibility, durability, and resistance to corrosion and chemicals, making them ideal for modern irrigation systems that require long-lasting performance. PVC pipes, composed of polyvinyl chloride, are rigid, cost-effective, and widely used in agricultural irrigation due to their ease of installation and resistance to UV degradation. Both pipe types serve critical roles in irrigation infrastructure, but the choice depends on factors such as soil conditions, pressure requirements, and environmental impact.

Durability and Lifespan Comparison

HDPE pipes exhibit superior durability compared to PVC pipes due to their enhanced resistance to corrosion, UV radiation, and impact, making them ideal for long-term irrigation systems. The flexible nature of HDPE allows it to withstand ground movements and pressure fluctuations without cracking, extending its operational lifespan beyond 50 years. Conversely, PVC pipes are prone to brittleness and cracking under extreme temperatures and UV exposure, typically offering a lifespan of 25 to 40 years in irrigation applications.

Installation and Flexibility Considerations

HDPE pipes offer superior flexibility and easier installation in irrigation systems due to their ability to withstand bending without cracking, making them ideal for uneven terrains. PVC pipes, while rigid and less adaptable, provide a straightforward installation process with reliable connections but may require more fittings to navigate complex layouts. The choice between HDPE and PVC hinges on site-specific conditions, with HDPE preferred for durability and adaptability and PVC favored for cost-effectiveness and structural stability.

Resistance to Chemicals and Corrosion

HDPE pipes exhibit superior resistance to a broad spectrum of chemicals and corrosion, making them ideal for irrigation systems exposed to fertilizers and pesticides. PVC pipes also offer decent chemical resistance but can degrade over time when exposed to strong solvents or prolonged corrosive conditions. The durability of HDPE pipes in harsh chemical environments extends the lifespan and reduces maintenance costs in agricultural irrigation.

Leakage Prevention and Jointing Techniques

HDPE pipes offer superior leakage prevention in irrigation systems due to their fusion welding jointing techniques, creating seamless and flexible connections that resist cracking and seepage under pressure. PVC pipes rely on solvent cement or rubber gasket joints, which are more prone to leaks and require regular maintenance to ensure integrity. The durability and jointing efficiency of HDPE systems reduce water loss and maintenance costs, making them ideal for sustainable irrigation applications.

Cost Analysis: HDPE vs PVC Pipes

HDPE pipes typically cost more upfront than PVC pipes due to higher material and manufacturing expenses, but their longevity and resistance to corrosion result in lower maintenance and replacement costs over time. PVC pipes offer a lower initial investment, making them attractive for budget-conscious projects, but their susceptibility to cracking and chemical damage can increase long-term repair expenses. Evaluating total cost of ownership reveals that HDPE pipes often provide better value in irrigation systems with challenging soil conditions and longer service life requirements.

Environmental Impact and Sustainability

HDPE pipes offer superior environmental benefits in irrigation systems due to their high recyclability and resistance to chemical degradation, resulting in a longer lifespan and reduced plastic waste compared to PVC pipes. PVC pipes involve toxic additives like phthalates, which can leach into soil and water, raising ecological and health concerns. Opting for HDPE pipes enhances sustainability by minimizing environmental pollution and supporting resource-efficient agricultural practices.

Suitability for Various Irrigation Methods

HDPE pipes offer superior flexibility and durability, making them ideal for drip and micro-irrigation systems where contouring to uneven terrain is essential. PVC pipes provide rigid structure and high-pressure resistance, suitable for sprinkler and surface irrigation requiring consistent water flow. Both pipe types cater to diverse irrigation needs, but HDPE's resistance to chemicals and UV exposure enhances long-term performance in variable field conditions.

Recommendations for Agricultural Applications

HDPE pipes offer superior flexibility, durability, and resistance to corrosion, making them ideal for high-pressure irrigation systems in rugged agricultural environments. PVC pipes, while cost-effective and easy to install, are less resistant to impact and UV degradation, which can limit their lifespan in outdoor irrigation setups. For long-term, sustainable agricultural irrigation, HDPE pipes are recommended due to their enhanced performance and lower maintenance requirements.

Related Important Terms

Hydrostatic Burst Pressure

HDPE pipes exhibit significantly higher hydrostatic burst pressure compared to PVC pipes, making them ideal for high-pressure irrigation systems requiring durability and resistance to cracking. Their superior tensile strength and flexibility enable HDPE pipes to withstand fluctuating water pressures and ground movements, ensuring long-term reliability in agricultural irrigation applications.

UV Stabilized Pipe (HDPE/PVC)

UV stabilized HDPE pipes for irrigation systems exhibit superior resistance to sunlight degradation and longer lifespan compared to UV stabilized PVC pipes, making them ideal for outdoor agricultural applications. HDPE's flexibility and higher impact strength reduce maintenance costs, while UV additives in both materials enhance durability under prolonged solar exposure.

Lateral Pipe Flexibility

HDPE pipes offer superior lateral pipe flexibility compared to PVC pipes, allowing for easier installation around curved terrains and uneven agricultural fields without the risk of cracking. This flexibility reduces joint requirements and maintenance costs, making HDPE a preferred choice for efficient and durable irrigation systems.

Micro-irrigation Compatibility

HDPE pipes offer superior flexibility, durability, and chemical resistance, making them highly compatible with micro-irrigation systems that require precise water flow and pressure control. PVC pipes, while cost-effective and widely used, have limited flexibility and lower resistance to environmental stress, potentially compromising the efficiency of micro-irrigation setups in varied agricultural conditions.

Solvent Welded Joint (PVC)

Solvent welded joints in PVC pipes create a chemically fused bond that ensures leak-proof connections ideal for irrigation systems, offering superior resistance to corrosion and chemical degradation compared to mechanical joints. Unlike HDPE pipes, which rely on heat fusion or mechanical fittings, PVC's solvent welding facilitates faster installation with consistent joint strength, enhancing system reliability in agricultural applications.

Electrofusion Coupling (HDPE)

HDPE pipes for irrigation systems offer superior durability and flexibility compared to PVC, with electrofusion coupling providing a reliable, leak-proof joint through a heat-generated fusion process that ensures seamless integration and resistance to soil pressure. This method significantly reduces maintenance costs and downtime by creating robust connections that withstand underground stress and environmental factors better than mechanical PVC fittings.

C-factor (Hydraulic Smoothness)

HDPE pipes exhibit a higher C-factor compared to PVC pipes, indicating superior hydraulic smoothness that reduces friction losses and enhances water flow efficiency in irrigation systems. This hydraulic advantage of HDPE pipes supports energy-saving pumping and uniform irrigation distribution, crucial for optimizing agricultural water management.

Permeation Resistance

HDPE pipes exhibit superior permeation resistance in irrigation systems due to their non-porous structure and higher chemical stability, effectively preventing contamination from agrochemicals and external pollutants. PVC pipes, while cost-effective, possess a more permeable matrix that can allow gradual infiltration of water-soluble chemicals, potentially compromising water quality.

Thermal Expansion Coefficient

HDPE pipes exhibit a significantly lower thermal expansion coefficient compared to PVC pipes, reducing deformation risks under temperature fluctuations in irrigation systems. This property ensures enhanced durability and consistent water flow, making HDPE pipes preferable for environments with wide temperature variations.

Leak-free Compression Fittings

HDPE pipes offer superior leak-free compression fittings compared to PVC pipes, ensuring robust, joint-tight irrigation systems resistant to pressure fluctuations and soil movement. The flexible nature of HDPE combined with its seamless fittings reduces maintenance costs and enhances water efficiency in agricultural irrigation networks.

HDPE Pipes vs PVC Pipes for Irrigation Systems Infographic

agridif.com

agridif.com