Parabolic blades offer enhanced soil penetration and efficient turning, reducing resistance and fuel consumption during ploughing. Swept-back blades provide better durability and minimize soil erosion by distributing forces more evenly across the blade surface. Choosing between these blade types depends on soil type and farming practices, with parabolic blades excelling in heavy soils and swept-back blades suited for lighter, erodible fields.

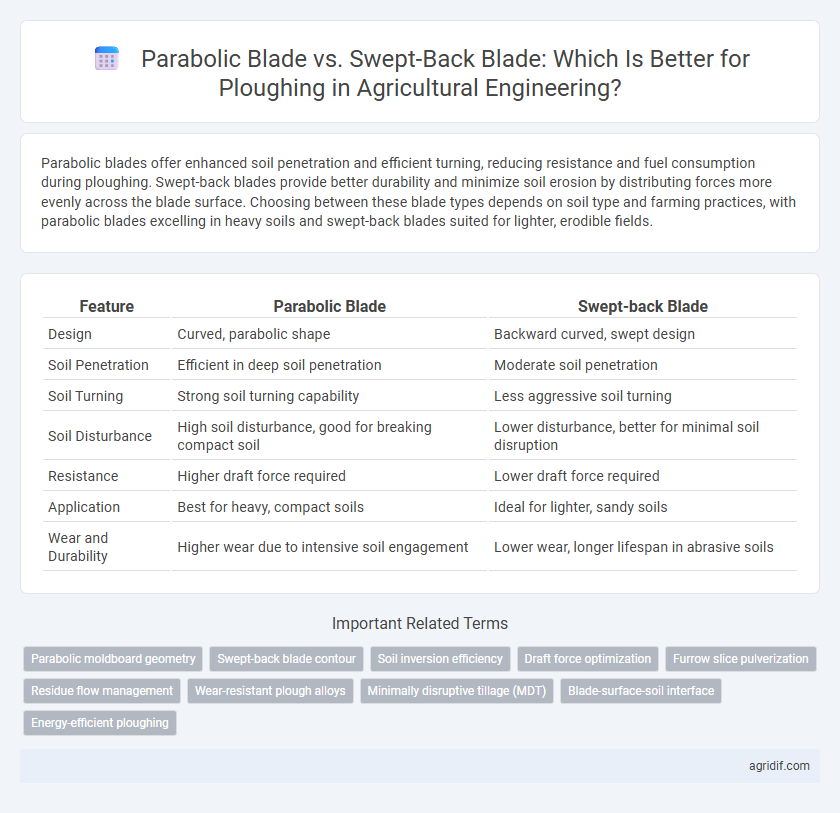

Table of Comparison

| Feature | Parabolic Blade | Swept-back Blade |

|---|---|---|

| Design | Curved, parabolic shape | Backward curved, swept design |

| Soil Penetration | Efficient in deep soil penetration | Moderate soil penetration |

| Soil Turning | Strong soil turning capability | Less aggressive soil turning |

| Soil Disturbance | High soil disturbance, good for breaking compact soil | Lower disturbance, better for minimal soil disruption |

| Resistance | Higher draft force required | Lower draft force required |

| Application | Best for heavy, compact soils | Ideal for lighter, sandy soils |

| Wear and Durability | Higher wear due to intensive soil engagement | Lower wear, longer lifespan in abrasive soils |

Introduction to Plough Blade Designs in Agricultural Engineering

Parabolic blades in agricultural engineering offer enhanced soil penetration and reduced draft force, improving ploughing efficiency by maintaining consistent soil turnover. Swept-back blades are designed to cut and lift soil with minimized resistance, promoting better soil aeration and residue mixing during tillage. Comparing these designs reveals that parabolic blades excel in heavy clay soils, while swept-back blades perform optimally in lighter, sandy soils, influencing implement selection based on soil type and farming requirements.

Anatomy of Parabolic Blades

Parabolic blades in ploughing feature a curved, spoon-shaped design that enhances soil penetration and turnover efficiency by reducing draft force and soil resistance. Their anatomy includes a convex surface that channels soil smoothly, minimizing clod size and improving aeration compared to the straighter Swept-back blades. This blade curvature optimizes soil inversion and burial of crop residues, leading to better seedbed preparation and increased agricultural productivity.

Structure and Features of Swept-back Blades

Swept-back blades feature a curved, aerodynamic design that reduces soil resistance and minimizes wear during ploughing operations. Their structure allows for efficient soil turnover with less draft force compared to parabolic blades, enhancing fuel efficiency and machine longevity. The robust construction of swept-back blades improves durability in abrasive soil conditions and supports smoother penetration and slicing through tough crop residues.

Soil Penetration Efficiency: Parabolic vs Swept-back Blades

Parabolic blades provide superior soil penetration efficiency compared to swept-back blades due to their curved shape that concentrates force onto a smaller area, enabling deeper and more precise cuts. Swept-back blades tend to generate more soil displacement and resistance, resulting in higher draft force requirements and reduced energy efficiency. Studies in agricultural engineering demonstrate that parabolic blades minimize soil compaction and improve ploughing consistency, enhancing overall tillage performance.

Impact on Soil Inversion and Mixing

Parabolic blades enhance soil inversion by providing a more uniform lift and turnover, leading to better incorporation of crop residues and organic matter. Swept-back blades reduce soil disturbance and minimize mixing, preserving soil structure and moisture retention while causing less compaction. The choice between these blade types directly influences soil aeration, nutrient distribution, and overall field preparation quality in agricultural engineering.

Fuel Efficiency and Power Consumption Comparison

Parabolic blades demonstrate superior fuel efficiency during ploughing by minimizing soil resistance and reducing power consumption compared to swept-back blades. Swept-back blades often require higher engine output to maintain consistent soil penetration, leading to increased fuel use. Field studies indicate parabolic blades can lower fuel consumption by up to 15% under similar working conditions, optimizing energy use in agricultural operations.

Blade Wear, Durability, and Maintenance

Parabolic blades exhibit reduced wear due to their optimal soil engagement angle, resulting in enhanced durability compared to swept-back blades that often experience uneven abrasion. The design of parabolic blades allows for more efficient soil displacement, minimizing maintenance frequency and extending service life. Swept-back blades may require more frequent sharpening and replacement because their curvature tends to trap soil, accelerating wear and increasing maintenance costs.

Suitability for Different Soil Types

Parabolic blades offer superior performance in heavy, clay-rich soils by providing deeper penetration and efficient soil turnover, reducing soil compaction. Swept-back blades excel in lighter, sandy, or loamy soils by minimizing soil disturbance and preserving soil structure during ploughing. Selecting the appropriate blade type enhances plough efficiency and promotes optimal soil health based on soil texture and composition.

Field Performance and Crop Yield Outcomes

Parabolic blades in ploughing offer superior soil turnover and reduced draft force, enhancing soil aeration and water infiltration compared to swept-back blades. Swept-back blades tend to perform better in minimizing soil disturbance and residue preservation, which can benefit certain crop rotations. Field trials indicate that parabolic blades generally lead to higher crop yields due to improved seedbed preparation and nutrient availability.

Future Trends in Plough Blade Technology

Parabolic blades enhance soil turnover efficiency and reduce draft force, while swept-back blades improve residue penetration and minimize soil disturbance. Future trends in plough blade technology emphasize advanced materials like wear-resistant composites and smart sensors for real-time performance monitoring. Integration of AI-driven adjustments aims to optimize blade angle and depth dynamically, increasing precision and sustainability in modern agricultural practices.

Related Important Terms

Parabolic moldboard geometry

Parabolic moldboard geometry in ploughing improves soil inversion and reduces draft force compared to traditional swept-back blades, enhancing fuel efficiency and minimizing wear on agricultural machinery. This design optimizes soil flow dynamics, leading to better residue burial and improved seedbed preparation in various soil conditions.

Swept-back blade contour

Swept-back blade contours in ploughing significantly reduce soil resistance and enhance draft efficiency by allowing smoother soil flow and minimizing clogging compared to parabolic blades. Their aerodynamic design improves fuel efficiency and promotes better soil inversion, leading to increased crop yield and reduced tractor wear.

Soil inversion efficiency

Parabolic blades exhibit higher soil inversion efficiency compared to swept-back blades by providing deeper and more uniform ploughing, which enhances soil aeration and residue incorporation. Swept-back blades tend to cause less soil disturbance, making them suitable for conservation tillage but less effective in thorough soil turnover and weed control.

Draft force optimization

Parabolic blades generate lower draft force compared to swept-back blades due to their curved design, which improves soil penetration and reduces resistance during ploughing. This optimization enhances fuel efficiency and overall tractor performance by minimizing the energy required to pull the implement through various soil conditions.

Furrow slice pulverization

Parabolic blades deliver superior furrow slice pulverization due to their curved geometry, which enhances soil cutting and fragmenting efficiency, leading to finer soil particles and improved seedbed preparation. Swept-back blades, while reducing draft force and wear, generally produce coarser soil aggregates, resulting in less effective pulverization compared to parabolic designs.

Residue flow management

Parabolic blades improve residue flow management by directing crop residues smoothly over the moldboard, reducing clogging and enhancing soil turnover efficiency. Swept-back blades disrupt residue flow with turbulent patterns, often causing residue accumulation that impedes ploughing performance and increases operator effort.

Wear-resistant plough alloys

Parabolic blades for ploughing, fabricated from wear-resistant plough alloys such as high-chromium cast iron and boron steel, offer enhanced durability and reduced soil friction compared to traditional shapes. Swept-back blades, though designed to minimize soil disturbance and improve cutting efficiency, typically require advanced alloy treatments to match the wear resistance and longevity provided by parabolic blade materials.

Minimally disruptive tillage (MDT)

Parabolic blades in ploughing enhance soil turnover efficiency while minimizing surface disruption, promoting better soil structure preservation essential for Minimally Disruptive Tillage (MDT) practices. Swept-back blades tend to create more soil disturbance and residue displacement, making them less suitable for MDT systems that aim to maintain soil integrity and reduce erosion.

Blade-surface-soil interface

Parabolic blades create a more efficient blade-surface-soil interface by concentrating soil displacement along a curved edge, enhancing penetration and reducing draft force during ploughing. Swept-back blades optimize soil flow by minimizing soil adhesion and lateral resistance, improving soil rollover but often requiring higher energy input compared to parabolic designs.

Energy-efficient ploughing

Parabolic blades exhibit superior energy efficiency in ploughing by minimizing soil resistance and reducing tractor fuel consumption compared to swept-back blades, which tend to cause higher draft force due to their shape. Optimizing blade geometry with parabolic design enhances soil turnover quality while lowering operational energy requirements in agricultural engineering.

Parabolic blade vs Swept-back blade for ploughing Infographic

agridif.com

agridif.com