Closed system hydroponics maximizes resource efficiency by recycling nutrient solutions and water, significantly reducing waste and minimizing environmental impact. Open system hydroponics, in contrast, often results in higher water and nutrient consumption due to continuous solution discharge and replacement. The closed system's ability to conserve resources makes it a more sustainable option for intensive agricultural production.

Table of Comparison

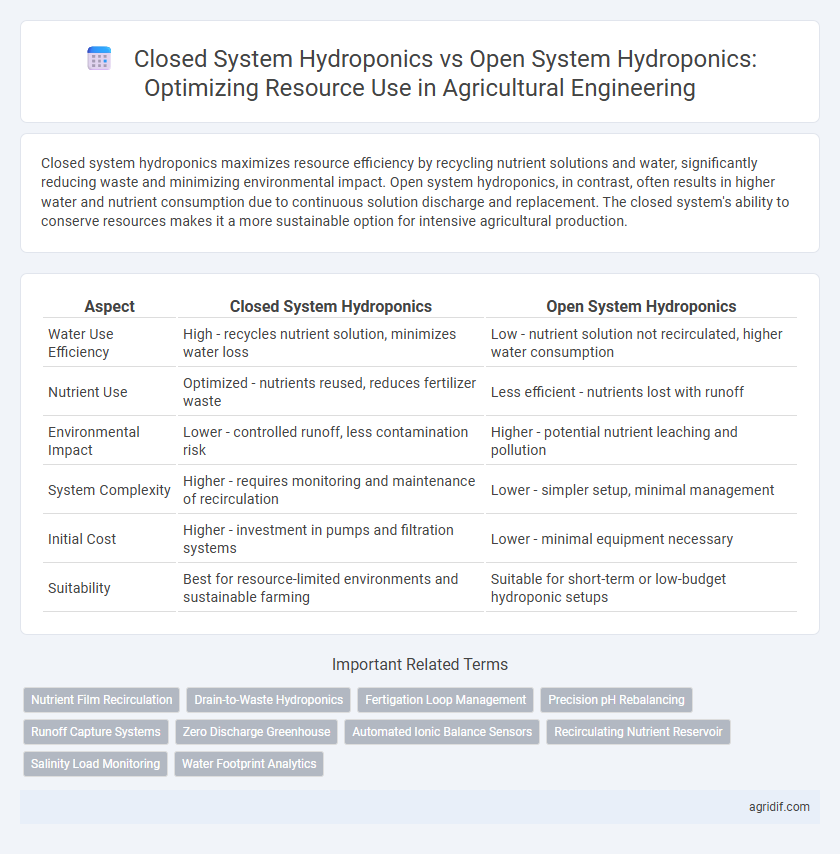

| Aspect | Closed System Hydroponics | Open System Hydroponics |

|---|---|---|

| Water Use Efficiency | High - recycles nutrient solution, minimizes water loss | Low - nutrient solution not recirculated, higher water consumption |

| Nutrient Use | Optimized - nutrients reused, reduces fertilizer waste | Less efficient - nutrients lost with runoff |

| Environmental Impact | Lower - controlled runoff, less contamination risk | Higher - potential nutrient leaching and pollution |

| System Complexity | Higher - requires monitoring and maintenance of recirculation | Lower - simpler setup, minimal management |

| Initial Cost | Higher - investment in pumps and filtration systems | Lower - minimal equipment necessary |

| Suitability | Best for resource-limited environments and sustainable farming | Suitable for short-term or low-budget hydroponic setups |

Introduction to Hydroponic Systems in Agriculture

Closed system hydroponics recirculates nutrient solutions, significantly reducing water and fertilizer consumption compared to open system hydroponics, which discharge excess nutrients and water after one use. This efficient resource management in closed systems minimizes environmental pollution and enhances sustainability in controlled environment agriculture. Key sensors and automation technologies further optimize nutrient delivery and water usage, improving crop yield and resource use efficiency.

Defining Closed and Open System Hydroponics

Closed system hydroponics recirculate nutrient solutions within a sealed loop, minimizing water and nutrient waste through precise control and reuse, optimizing resource efficiency. In contrast, open system hydroponics deliver nutrient solutions to plants once and then discharge excess solution, resulting in higher water and nutrient consumption with potential environmental runoff. Understanding these fundamental distinctions helps agricultural engineers design irrigation setups that balance resource use, crop yield, and sustainability.

Water Use Efficiency in Closed vs Open Hydroponic Systems

Closed system hydroponics significantly enhances water use efficiency by recycling nutrient solutions and minimizing evaporation and runoff losses, resulting in up to 90% less water consumption compared to open systems. In contrast, open hydroponic systems continuously discharge excess water, leading to higher water demand and increased nutrient wastage. This efficient water management in closed systems supports sustainable agriculture by reducing freshwater extraction and lowering environmental contamination.

Nutrient Management and Recycling in Hydroponic Models

Closed system hydroponics maximizes nutrient management through precise control and recycling of nutrient solutions, minimizing waste and reducing environmental impact. Open system hydroponics, while simpler, often leads to nutrient runoff and requires frequent replenishment, resulting in higher consumption of water and fertilizers. Optimizing nutrient recycling in closed systems enhances sustainability by conserving resources and maintaining consistent plant growth conditions.

Energy Consumption Comparison: Closed vs Open Systems

Closed system hydroponics significantly reduces energy consumption compared to open systems by recirculating nutrient solutions, minimizing water and nutrient wastage, and decreasing the need for continuous pumping and heating. Open systems require constant input of fresh nutrient solution and energy to manage water flow and temperature, leading to higher overall energy demand. Energy efficiency in closed systems enhances sustainability, lowers operational costs, and optimizes resource use in agricultural engineering.

Environmental Impact and Waste Generation

Closed system hydroponics recirculates nutrient solutions, significantly reducing water consumption and minimizing nutrient runoff, which lowers the environmental impact compared to open systems. Open system hydroponics involves continuous flow and disposal of excess solutions, leading to higher waste generation and potential contamination of surrounding ecosystems. Efficient resource use in closed systems promotes sustainability by conserving water and reducing chemical waste, essential for environmentally responsible agricultural engineering.

Disease Control and Biosecurity in System Types

Closed system hydroponics offers superior disease control and biosecurity by recirculating nutrient solutions within a sealed environment, minimizing pathogen introduction and spread. In contrast, open system hydroponics exposes plants to external elements and untreated water sources, increasing risks of contamination and disease outbreaks. Efficient resource use in closed systems reduces nutrient loss and water waste, enhancing sustainability and crop health.

Cost Analysis and Economic Feasibility

Closed system hydroponics optimizes resource use by recycling nutrient solutions, reducing water and fertilizer consumption, thereby lowering operational costs compared to open systems that result in higher nutrient loss and waste. The initial capital investment for closed systems is higher due to advanced equipment and monitoring technologies; however, long-term economic feasibility improves with reduced input costs and increased crop yields. Open system hydroponics has lower startup costs but incurs greater ongoing expenses from frequent nutrient replenishment and water usage, making it less cost-effective for sustainable production.

Scalability and Practicality for Commercial Agriculture

Closed system hydroponics offers superior resource efficiency by recycling nutrient solutions, significantly reducing water and fertilizer consumption, which enhances scalability for large-scale commercial agriculture. Open system hydroponics, while simpler and less costly initially, risks nutrient runoff and higher resource waste, limiting its practicality for extensive commercial operations. The closed system's ability to maintain precise nutrient control and minimize environmental impact makes it more viable for sustainable, scalable agricultural engineering projects.

Future Trends and Innovations in Hydroponic Resource Use

Closed system hydroponics offers significant resource efficiency by recirculating nutrient solutions, reducing water and fertilizer consumption compared to open systems, which discharge excess solutions and lead to higher resource loss. Future trends focus on integrating AI-driven monitoring and smart sensors to optimize nutrient delivery and water use, enhancing sustainability and crop yields. Innovations in biodegradable substrates and renewable energy-powered systems are poised to further minimize environmental impact and resource dependency in hydroponic farming.

Related Important Terms

Nutrient Film Recirculation

Closed system hydroponics in Nutrient Film Technique (NFT) recirculate nutrient solutions, significantly reducing water and nutrient waste compared to open system hydroponics, where excess solution is discarded after single use. This recirculation enhances resource efficiency by maintaining optimal nutrient concentrations and minimizing environmental runoff, making it more sustainable for intensive agricultural operations.

Drain-to-Waste Hydroponics

Drain-to-Waste hydroponics, an open system, consumes more water and nutrients compared to closed system hydroponics due to continuous discharge of unused solutions, leading to higher resource wastage. Closed systems recirculate nutrient solutions, enhancing water and nutrient use efficiency and minimizing environmental impact in agricultural engineering practices.

Fertigation Loop Management

Closed system hydroponics optimizes resource use by recirculating nutrient solutions, minimizing water and fertilizer waste through precise fertigation loop management, which enhances nutrient uptake efficiency and reduces environmental runoff. In contrast, open system hydroponics discharges excess nutrient solutions, resulting in higher resource consumption and requiring more frequent monitoring to prevent nutrient imbalances and environmental contamination.

Precision pH Rebalancing

Closed system hydroponics enhances resource efficiency by enabling precise pH rebalancing through continuous monitoring and automated adjustments, minimizing nutrient loss and water waste. In contrast, open system hydroponics often experiences greater pH fluctuations and resource depletion due to runoff and less controlled nutrient recycling.

Runoff Capture Systems

Closed system hydroponics significantly enhances resource efficiency by recycling nutrient solutions and minimizing water loss through runoff capture systems, effectively reducing environmental contamination. In contrast, open system hydroponics allows nutrient-rich runoff to escape, increasing water consumption and the risk of soil and water pollution due to lack of containment and reuse mechanisms.

Zero Discharge Greenhouse

Closed system hydroponics in zero discharge greenhouses maximizes resource efficiency by recycling nutrient solutions and minimizing water loss, resulting in reduced environmental impact and lower input costs. In contrast, open system hydroponics tend to discharge excess nutrient solutions, leading to higher water consumption and potential nutrient runoff, which challenges sustainable resource management in controlled environment agriculture.

Automated Ionic Balance Sensors

Automated ionic balance sensors in closed system hydroponics optimize nutrient use by continuously monitoring and adjusting ion concentrations, reducing water and fertilizer waste compared to open systems where nutrient solutions are periodically replaced and more prone to depletion. This technology enhances resource efficiency and sustainability by maintaining precise ionic equilibrium, minimizing runoff, and lowering environmental impact in agricultural engineering applications.

Recirculating Nutrient Reservoir

Closed system hydroponics optimizes resource use by recirculating nutrient solutions through a recirculating nutrient reservoir, minimizing water and fertilizer waste compared to open systems that often discharge excess nutrients. This recirculation enhances sustainability by reducing inputs and preventing environmental pollution, making closed systems more efficient for agricultural engineering applications focused on resource conservation.

Salinity Load Monitoring

Closed system hydroponics offers precise salinity load monitoring by recirculating nutrient solutions, minimizing water and fertilizer waste while preventing salt accumulation in the root zone. In contrast, open system hydroponics discharge excess nutrient solution, increasing salinity fluctuation risks and requiring more frequent water quality adjustments to maintain optimal crop growth.

Water Footprint Analytics

Closed system hydroponics significantly reduces water footprint by recirculating nutrient solutions, minimizing water loss through evaporation and runoff, which enhances water use efficiency in agricultural practices. In contrast, open system hydroponics experiences higher water consumption due to nutrient solution discharge and greater vulnerability to contamination, resulting in increased water footprint and less sustainable water management.

Closed system hydroponics vs open system hydroponics for resource use Infographic

agridif.com

agridif.com