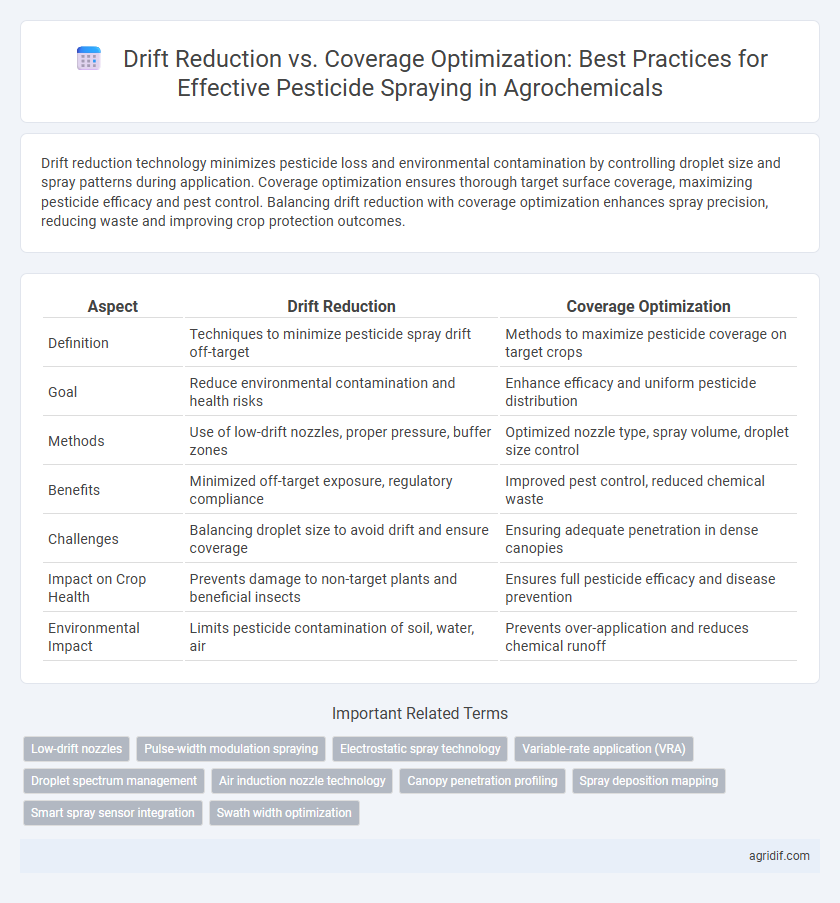

Drift reduction technology minimizes pesticide loss and environmental contamination by controlling droplet size and spray patterns during application. Coverage optimization ensures thorough target surface coverage, maximizing pesticide efficacy and pest control. Balancing drift reduction with coverage optimization enhances spray precision, reducing waste and improving crop protection outcomes.

Table of Comparison

| Aspect | Drift Reduction | Coverage Optimization |

|---|---|---|

| Definition | Techniques to minimize pesticide spray drift off-target | Methods to maximize pesticide coverage on target crops |

| Goal | Reduce environmental contamination and health risks | Enhance efficacy and uniform pesticide distribution |

| Methods | Use of low-drift nozzles, proper pressure, buffer zones | Optimized nozzle type, spray volume, droplet size control |

| Benefits | Minimized off-target exposure, regulatory compliance | Improved pest control, reduced chemical waste |

| Challenges | Balancing droplet size to avoid drift and ensure coverage | Ensuring adequate penetration in dense canopies |

| Impact on Crop Health | Prevents damage to non-target plants and beneficial insects | Ensures full pesticide efficacy and disease prevention |

| Environmental Impact | Limits pesticide contamination of soil, water, air | Prevents over-application and reduces chemical runoff |

Understanding Drift Reduction in Agrochemical Application

Drift reduction in agrochemical application involves techniques and technologies designed to minimize the off-target movement of pesticides, ensuring precise deposition on intended crops and reducing environmental contamination. Methods such as using low-drift nozzles, optimizing droplet size, and adjusting spray pressure play critical roles in mitigating airborne pesticide drift. Effective drift reduction not only enhances application efficiency but also protects surrounding ecosystems and complies with regulatory standards for sustainable agriculture.

Importance of Spray Coverage Optimization in Crop Protection

Spray coverage optimization ensures uniform pesticide distribution on crop foliage, maximizing pest control efficacy while minimizing chemical wastage. Proper coverage reduces the risk of missed areas vulnerable to pest infestation, enhancing overall crop protection and yield. Optimizing coverage also supports environmental safety by reducing runoff and minimizing the need for excessive pesticide applications.

Factors Influencing Pesticide Drift and Coverage

Pesticide drift is primarily influenced by droplet size, wind speed, and spray pressure, with smaller droplets and higher winds increasing the risk of drift, while larger droplets improve deposition. Coverage optimization depends on nozzle type, spray volume, and application technique to ensure uniform pesticide distribution and effective target coverage. Balancing drift reduction and coverage involves selecting appropriate spray parameters that minimize off-target movement without compromising thorough coverage of the crop canopy.

Technologies for Drift Reduction in Spraying

Technologies for drift reduction in pesticide spraying include air induction nozzles, which create larger droplets to minimize off-target movement, and electrostatic sprayers that charge droplets for better adhesion to plant surfaces. Precision GPS-guided spraying systems enhance coverage optimization by controlling spray patterns and ensuring uniform application, reducing waste and environmental impact. Combining these technologies improves efficacy by balancing drift reduction with optimal coverage in agrochemical applications.

Nozzle Selection: Balancing Drift Reduction and Coverage

Selecting the right nozzle is critical for balancing drift reduction and coverage optimization in pesticide spraying, as nozzle design influences droplet size, spray pattern, and application rate. Drift reduction nozzles produce larger droplets that minimize off-target movement but may compromise coverage uniformity, while finer droplets enhance coverage but increase drift potential. Choosing nozzles that deliver medium-sized droplets and adjustable spray angles helps achieve effective pesticide deposition with reduced environmental impact and greater application efficiency.

The Role of Weather Conditions in Drift and Coverage

Weather conditions such as wind speed, temperature, and humidity critically influence pesticide drift and coverage effectiveness during spraying applications. High wind speeds increase drift potential, reducing target coverage and posing environmental risks, while low humidity can cause faster droplet evaporation, limiting coverage area. Optimizing spray timing by monitoring weather forecasts enhances drift reduction strategies and ensures uniform pesticide coverage for improved pest control.

Adjuvants: Enhancing Coverage without Increasing Drift

Adjuvants play a critical role in optimizing pesticide coverage by improving droplet spread and adhesion on target surfaces while minimizing droplet drift. Formulations such as surfactants and spreaders enhance pesticide retention and uniformity, ensuring efficient coverage without necessarily increasing spray volume or droplet size. This balance reduces off-target movement, promoting environmental safety and maximizing pesticide efficacy.

Regulatory Guidelines on Drift and Coverage Optimization

Regulatory guidelines on agrochemical application emphasize minimizing pesticide drift to prevent environmental contamination and non-target exposure, often mandating specific nozzle types and spray pressure settings. Coverage optimization is crucial for ensuring effective pest control while adhering to legal limits on application rates, relying on precise calibration and real-time monitoring technologies. Compliance with EPA drift reduction standards and application best practices enhances both environmental safety and crop protection efficacy.

Economic Impacts of Drift vs. Coverage in Pesticide Use

Economic impacts of drift versus coverage optimization in pesticide use significantly affect farm profitability and sustainability. Drift reduction minimizes costly pesticide loss and environmental fines, while coverage optimization enhances crop protection efficiency, reducing the need for repeat applications and lowering input costs. Balancing these factors leads to improved yield quality, decreased chemical wastage, and overall cost-effectiveness in agrochemical management.

Best Practices for Achieving Optimal Drift Reduction and Coverage

Achieving optimal drift reduction and coverage in pesticide spraying requires precise nozzle selection, maintaining appropriate spray pressure, and adjusting boom height to minimize off-target movement while ensuring uniform droplet distribution. Utilizing adjuvants that modify droplet size enhances deposit consistency and reduces evaporation, thereby improving target coverage and reducing environmental contamination. Regular equipment calibration and implementing GPS-guided variable rate application further optimize spray patterns, maximizing efficacy and minimizing pesticide waste.

Related Important Terms

Low-drift nozzles

Low-drift nozzles significantly reduce pesticide drift by producing larger droplets that minimize airborne movement, thereby enhancing environmental safety and application precision. Optimizing coverage involves balancing droplet size to ensure uniform distribution without compromising drift reduction, making low-drift nozzles ideal for efficient and targeted pesticide delivery in agrochemical applications.

Pulse-width modulation spraying

Pulse-width modulation (PWM) spraying technology significantly enhances drift reduction by maintaining consistent droplet size and spray pressure, minimizing off-target pesticide dispersal. Simultaneously, PWM enables precise coverage optimization by adjusting nozzle output in real-time, ensuring uniform pesticide distribution across varying terrain and crop densities.

Electrostatic spray technology

Electrostatic spray technology significantly enhances pesticide coverage by charging droplets to improve adhesion and uniform distribution on plant surfaces, reducing the volume of spray needed. This method also minimizes drift by controlling droplet size and trajectory, ensuring targeted application and decreasing environmental contamination.

Variable-rate application (VRA)

Variable-rate application (VRA) technology enhances pesticide spraying by optimizing coverage precisely according to crop variability, reducing chemical waste and minimizing off-target drift. Drift reduction techniques combined with VRA improve environmental safety and pesticide efficacy by adjusting spray volume and droplet size to match field-specific conditions.

Droplet spectrum management

Drift reduction and coverage optimization in pesticide spraying are primarily achieved through droplet spectrum management, where selecting an appropriate droplet size distribution minimizes off-target movement while ensuring uniform pesticide deposition. Fine-tuning nozzle types and operating pressures can produce medium to coarse droplets that reduce drift potential yet maintain adequate canopy coverage, balancing environmental safety with application efficacy.

Air induction nozzle technology

Air induction nozzle technology significantly reduces pesticide drift by producing larger, air-filled droplets that resist airborne movement while enhancing coverage uniformity on crop surfaces. This balance optimizes pesticide efficacy, minimizing environmental impact without compromising spray deposition.

Canopy penetration profiling

Drift reduction technologies minimize off-target spray loss by controlling droplet size and spray atomization, enhancing application accuracy and environmental safety. Canopy penetration profiling optimizes coverage by analyzing spray deposition within plant layers, ensuring pesticides reach target pests effectively while reducing waste and improving overall efficacy.

Spray deposition mapping

Spray deposition mapping enhances pesticide application by precisely measuring droplet impact and coverage uniformity, enabling better drift reduction while optimizing coverage. Advanced mapping technologies integrate real-time data to balance effective pesticide distribution and minimize off-target movement, improving overall spray efficiency in agrochemical applications.

Smart spray sensor integration

Smart spray sensor integration enhances pesticide application by precisely adjusting droplet size and spray patterns, effectively reducing drift while maximizing coverage on target crops. This technology leverages real-time environmental data and plant canopy analysis to optimize spray deposition, improving agrochemical efficiency and minimizing environmental impact.

Swath width optimization

Optimizing swath width in pesticide spraying significantly enhances coverage uniformity while minimizing drift potential by ensuring precise application patterns that reduce off-target movement. Balancing swath width adjustments with droplet size and spray pressure is essential for maximizing agrochemical efficacy and environmental safety.

Drift reduction vs Coverage optimization for pesticide spraying Infographic

agridif.com

agridif.com