Hand-milking allows for gentle handling and close monitoring of dairy cows, which can reduce stress and detect early signs of mastitis. Machine-milking increases efficiency and consistency, enabling higher productivity on large-scale farms while maintaining udder health through regulated suction and pulsation. Choosing between methods depends on herd size, labor availability, and production goals to optimize milk yield and animal welfare.

Table of Comparison

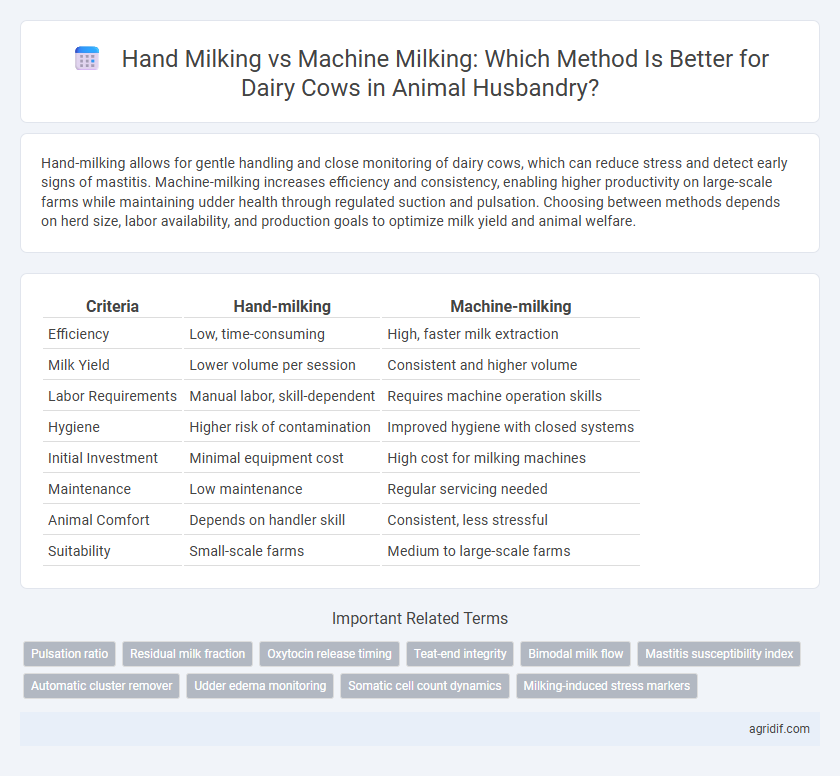

| Criteria | Hand-milking | Machine-milking |

|---|---|---|

| Efficiency | Low, time-consuming | High, faster milk extraction |

| Milk Yield | Lower volume per session | Consistent and higher volume |

| Labor Requirements | Manual labor, skill-dependent | Requires machine operation skills |

| Hygiene | Higher risk of contamination | Improved hygiene with closed systems |

| Initial Investment | Minimal equipment cost | High cost for milking machines |

| Maintenance | Low maintenance | Regular servicing needed |

| Animal Comfort | Depends on handler skill | Consistent, less stressful |

| Suitability | Small-scale farms | Medium to large-scale farms |

Introduction to Hand-Milking and Machine-Milking

Hand-milking involves manually extracting milk from dairy cows using hands, relying on skilled technique to ensure efficient milk flow and animal comfort. Machine-milking utilizes mechanical milking machines designed to simulate natural sucking rhythms, improving milking speed and hygiene while reducing labor intensity. Both methods play critical roles in dairy farming depending on herd size, economic resources, and farm management practices.

Historical Evolution of Milking Methods

Hand-milking of dairy cows, an ancient practice dating back thousands of years, relied on manual dexterity and intimate animal handling, shaping early dairy farming communities. The introduction of machine-milking in the late 19th and early 20th centuries revolutionized milk production by significantly increasing efficiency and hygiene standards, propelled by innovations such as the vacuum milking system patented in 1893. This technological evolution transformed animal husbandry practices, enabling large-scale dairy operations and contributing to modern food security and agricultural economies.

Equipment and Tools Required

Hand-milking requires minimal equipment, typically only a clean bucket and a stool, making it accessible yet labor-intensive. Machine-milking involves specialized milking machines equipped with vacuum pumps, pulsators, and hygienic teat cups that enhance efficiency and consistency in milk extraction. Automated systems often incorporate milk storage units and cleaning mechanisms, requiring higher initial investment and maintenance compared to manual tools.

Labor and Time Efficiency Comparison

Hand-milking dairy cows requires significantly more labor and time, with an average of 30 to 60 minutes per cow compared to 5 to 10 minutes using machine-milking systems. Machine-milking enhances labor efficiency by allowing operators to milk multiple cows simultaneously, reducing overall manpower needs on dairy farms. Time savings from mechanical milking directly translate into increased productivity and lower labor costs in large-scale dairy operations.

Impact on Milk Yield and Quality

Hand-milking often results in lower milk yield compared to machine-milking due to slower and less consistent extraction, which can also affect the completeness of milking. Machine-milking enhances milk yield by providing uniform stimulation and reducing milking time, leading to increased efficiency and higher daily output. Regarding milk quality, machine-milking systems equipped with proper hygiene protocols minimize contamination risks and maintain better somatic cell counts, thus preserving milk freshness and safety.

Animal Welfare and Udder Health

Hand-milking allows for gentle handling of dairy cows, reducing stress and minimizing the risk of teat injuries, which promotes better animal welfare and udder health. Machine-milking, when properly maintained and adjusted, provides consistent milking pressure and stimulates milk flow efficiently but can cause teat-end damage if improperly used. Regular cleaning and monitoring of milking equipment are crucial to prevent mastitis and maintain optimal udder health in machine-milked cows.

Hygiene and Contamination Risks

Hand-milking of dairy cows poses higher hygiene challenges due to direct contact with the udder and potential for inconsistent cleaning practices, increasing the risk of bacterial contamination such as Staphylococcus aureus and Escherichia coli. Machine-milking systems, when properly maintained and sanitized, provide a more controlled environment that minimizes exposure to contaminants and supports standardization of milking hygiene protocols. Optimal milking hygiene reduces somatic cell count and mastitis incidence, which are critical for ensuring milk safety and quality.

Economic Considerations for Farmers

Hand-milking requires less initial investment but is labor-intensive and limits herd size, impacting overall productivity and profitability. Machine-milking systems demand higher upfront costs but enhance efficiency, increase milk yield, and reduce labor expenses over time, offering better scalability for larger dairy operations. Economic decisions depend on farm size, labor availability, and long-term financial goals to maximize return on investment in dairy farming.

Environmental Impacts of Each Method

Hand-milking dairy cows consumes no electricity and generates minimal greenhouse gas emissions, making it a low-impact environmental option favored in small-scale or traditional farms. Machine-milking, while increasing efficiency and milk yield, relies on electricity and water consumption, potentially increasing the farm's carbon footprint and resource use. Advances in energy-efficient milking machines and renewable energy integration help mitigate these environmental impacts in larger dairy operations.

Choosing the Right Milking Method for Your Dairy Operation

Hand-milking offers precise control and lower initial costs, ideal for small-scale dairy farms or where gentle handling is crucial for cow comfort and health. Machine-milking significantly improves efficiency and consistency, supporting larger herds with automated milking systems that enhance milk hygiene and quantity. Evaluating herd size, labor availability, and budget helps dairy farmers select the optimal milking method to maximize productivity and animal welfare.

Related Important Terms

Pulsation ratio

Hand-milking relies on the natural rhythm of the milker's hands, often resulting in inconsistent pulsation ratios that can affect teat health and milk flow efficiency, whereas machine-milking systems typically maintain a standardized pulsation ratio of 60:40 or 65:35, optimizing teat stimulation and milk extraction. Maintaining an appropriate pulsation ratio in machine milking is critical for preventing teat-end damage, reducing mastitis risk, and maximizing milking speed and udder comfort in dairy cows.

Residual milk fraction

Hand-milking often results in a higher residual milk fraction compared to machine-milking, potentially reducing total milk yield and impacting udder health. Machine-milking systems apply consistent suction and pulsation, effectively minimizing residual milk and promoting optimal dairy cow productivity.

Oxytocin release timing

Hand-milking stimulates the release of oxytocin through direct teat stimulation, typically resulting in a faster and more pronounced hormonal response within 1-2 minutes, enhancing milk let-down efficiency. In contrast, machine-milking may delay oxytocin release due to mechanical suction patterns, potentially affecting milk yield and udder health if not properly calibrated.

Teat-end integrity

Hand-milking preserves teat-end integrity by applying gentle, controlled pressure that reduces the risk of teat tissue damage and infection compared to machine-milking. Machine-milking, if improperly adjusted, can cause hyperkeratosis and canal erosion, leading to higher susceptibility to mastitis and decreased milk quality.

Bimodal milk flow

Hand-milking produces a natural bimodal milk flow with distinct let-down and stripping phases, enhancing teat stimulation and milk ejection, while machine-milking tends to produce a more continuous, unimodal flow that may reduce teat stimulation efficiency. Optimizing milking techniques to mimic bimodal flow can improve milk yield and udder health, reducing the risk of teat tissue damage and mastitis in dairy cows.

Mastitis susceptibility index

Hand-milking reduces the mechanical stress on dairy cows' teats, resulting in a lower Mastitis susceptibility index compared to machine-milking, which can create inconsistent suction and teat-end damage. Studies indicate that machine-milking increases the risk of mastitis by 15-30% due to improper milking machine maintenance and technique, impacting udder health and milk quality.

Automatic cluster remover

Automatic cluster removers in machine-milking systems enhance dairy cow health by preventing overmilking, reducing teat damage, and improving overall milk quality. Hand-milking lacks this precise control mechanism, often leading to inconsistent milking times and higher risks of udder infections.

Udder edema monitoring

Hand-milking allows for immediate tactile assessment of udder edema in dairy cows, enabling early detection and manual relief of swelling to prevent complications. Machine-milking, while efficient for large-scale operations, requires integrated udder health monitoring systems to accurately detect edema and minimize the risk of mastitis and impaired milk flow.

Somatic cell count dynamics

Hand-milking generally results in a lower somatic cell count (SCC) due to reduced udder stress and minimal mechanical injury, while machine-milking can cause micro-traumas that elevate SCC over time. Maintaining optimal milking hygiene and regular equipment maintenance is essential to control SCC dynamics and prevent mastitis in dairy herds.

Milking-induced stress markers

Hand-milking dairy cows typically results in lower cortisol levels and decreased heart rate variability compared to machine-milking, indicating reduced milking-induced stress markers. Research shows that mechanical milking machines can increase somatic cell counts and oxidative stress, impacting overall cow welfare and milk quality.

Hand-milking vs Machine-milking for dairy cows Infographic

agridif.com

agridif.com