Flow-through tanks for trout rearing rely on a continuous supply of fresh water that removes waste and supplies oxygen, supporting high water quality but requiring significant water resources. Closed loop systems recirculate water through filtration and aeration, minimizing water usage and enhancing environmental sustainability while demanding more complex management and higher initial investment. Choosing between these systems depends on balancing water availability, environmental impact, and operational costs to optimize trout growth and health.

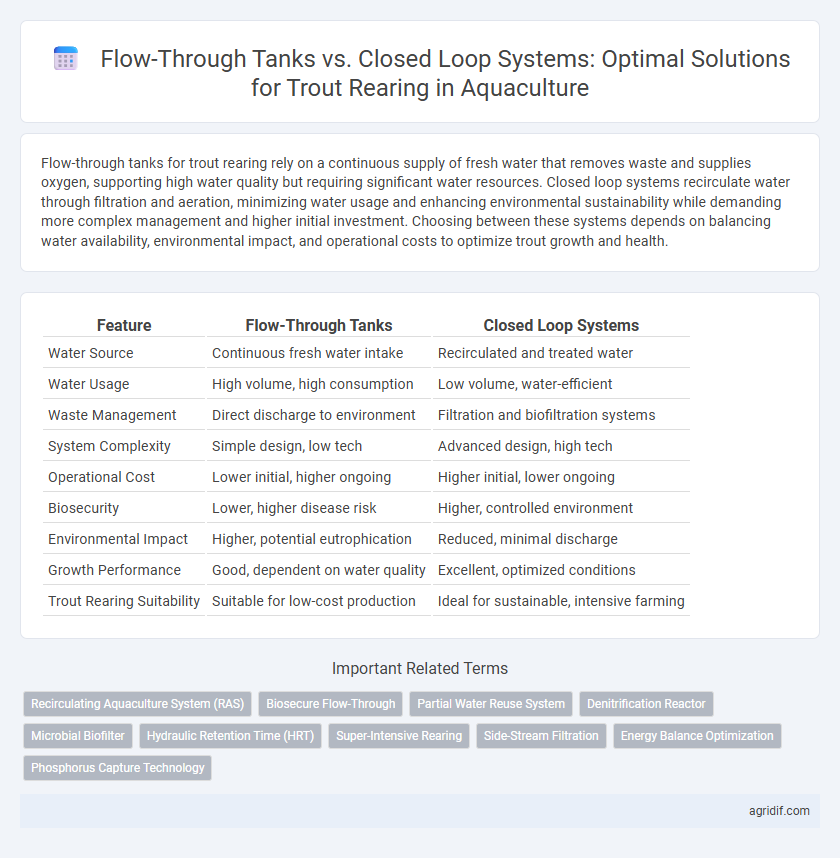

Table of Comparison

| Feature | Flow-Through Tanks | Closed Loop Systems |

|---|---|---|

| Water Source | Continuous fresh water intake | Recirculated and treated water |

| Water Usage | High volume, high consumption | Low volume, water-efficient |

| Waste Management | Direct discharge to environment | Filtration and biofiltration systems |

| System Complexity | Simple design, low tech | Advanced design, high tech |

| Operational Cost | Lower initial, higher ongoing | Higher initial, lower ongoing |

| Biosecurity | Lower, higher disease risk | Higher, controlled environment |

| Environmental Impact | Higher, potential eutrophication | Reduced, minimal discharge |

| Growth Performance | Good, dependent on water quality | Excellent, optimized conditions |

| Trout Rearing Suitability | Suitable for low-cost production | Ideal for sustainable, intensive farming |

Introduction to Trout Rearing Systems

Flow-through tanks and closed loop systems represent two primary methods for trout rearing, each offering distinct advantages in water quality management and operational efficiency. Flow-through tanks rely on continuous freshwater supply, ensuring oxygenation and waste removal but demanding higher water volumes and infrastructure. Closed loop systems recycle water within a contained environment, optimizing resource use and enabling better control over water parameters critical for trout health and growth.

Overview of Flow-Through Tanks

Flow-through tanks for trout rearing utilize a continuous supply of fresh water that flows through the system, effectively removing waste and maintaining optimal oxygen levels for fish health. These tanks require significant water volume and proper effluent management to minimize environmental impact, often relying on nearby natural water sources. Despite higher water usage, flow-through systems offer simpler design and lower operational costs compared to closed loop recirculating aquaculture systems (RAS).

Overview of Closed Loop (Recirculating) Aquaculture Systems

Closed loop recirculating aquaculture systems (RAS) optimize water use by continuously filtering and recycling water, creating a controlled environment essential for trout rearing. These systems enhance biosecurity, reduce water consumption by up to 90%, and enable precise regulation of temperature, oxygen, and waste removal. High-density trout production in RAS improves growth rates and minimizes environmental impact compared to traditional flow-through tanks.

Water Quality Management in Both Systems

Flow-through tanks for trout rearing continuously supply fresh water, effectively diluting waste and maintaining stable dissolved oxygen levels but can lead to higher water usage and discharge concerns. Closed loop systems recycle water, employing biofilters and mechanical filtration to control ammonia and nitrite concentrations, optimizing water quality while conserving resources. Both systems require precise monitoring of pH, temperature, and nitrogen compounds to ensure optimal trout health and growth performance.

Resource Efficiency and Energy Consumption

Flow-through tanks for trout rearing require high volumes of water and continuous flushing, leading to increased water usage and energy consumption due to pumps operating constantly. Closed loop systems recycle water by filtering and treating it, significantly reducing water demand and enabling precise control over water quality, which improves resource efficiency. Energy consumption in closed loop systems is concentrated in filtration and aeration units but remains lower overall compared to the extensive water exchange needs of flow-through tanks.

Disease Control and Biosecurity Considerations

Flow-through tanks offer continuous water exchange, reducing pathogen buildup and helping maintain water quality, but pose higher risks of disease introduction from external water sources. Closed loop systems recycle water, allowing strict control over temperature and water chemistry, which enhances biosecurity by minimizing pathogen entry and facilitating localized disease management. Implementing effective filtration and disinfection protocols in both systems is critical to prevent disease outbreaks and protect trout health in aquaculture operations.

Environmental Impact and Sustainability

Flow-through tanks for trout rearing consume large volumes of freshwater and discharge untreated effluents, leading to habitat disruption and nutrient pollution in surrounding ecosystems. Closed loop systems, such as recirculating aquaculture systems (RAS), significantly reduce water usage by recycling and treating water onsite, minimizing environmental footprint and mitigating contamination risks. Implementing closed loop technologies enhances sustainability by conserving water resources and promoting waste management practices aligned with eco-friendly aquaculture standards.

Economic Analysis: Cost and Profitability Factors

Flow-through tanks for trout rearing typically incur higher water usage costs and environmental discharge fees but benefit from lower initial infrastructure expenses compared to closed loop systems, which require significant investment in filtration and recirculation technology. Economic analysis reveals closed loop systems enhance profitability through reduced water consumption, improved biosecurity, and increased growth rates, offsetting the elevated operational and maintenance costs over time. Profit margins in closed loop systems tend to be more stable and scalable, particularly in regions with stringent environmental regulations or limited water availability.

Suitability for Different Scales of Production

Flow-through tanks are ideal for large-scale trout farming due to their simple design and constant water exchange, supporting high stocking densities and continuous oxygen supply. Closed loop systems provide greater control over water quality and waste management, making them more suitable for small to medium operations aiming for sustainability and lower environmental impact. Each system's scalability depends on resource availability and production goals, with flow-through favoring volume and closed loop prioritizing efficiency and eco-friendliness.

Selecting the Right System for Trout Rearing

Flow-through tanks provide consistent water renewal, crucial for maintaining oxygen levels and waste removal in trout rearing, but they require high water volumes and strong water sources. Closed loop systems optimize water use by recycling and filtering water, leading to better control of temperature, oxygen, and waste, benefiting high-density trout production. Selecting the right system depends on factors like water availability, environmental impact, operational costs, and production goals, with closed loop systems favored in areas with limited water resources.

Related Important Terms

Recirculating Aquaculture System (RAS)

Recirculating Aquaculture Systems (RAS) offer superior water quality management and resource efficiency compared to traditional flow-through tanks, enabling precise control over temperature, oxygen levels, and waste removal critical for optimal trout growth. By continuously filtering and reusing water, RAS reduce environmental impact and operational costs while enhancing biosecurity and stocking density in trout rearing operations.

Biosecure Flow-Through

Biosecure flow-through tanks for trout rearing enhance disease prevention by continuously supplying fresh, pathogen-free water, minimizing biofilm buildup and pathogen accumulation compared to closed loop systems. This method supports optimal trout growth and health by maintaining stable water quality parameters and reducing cross-contamination risks inherent in recirculating aquaculture systems.

Partial Water Reuse System

Partial water reuse systems in flow-through tanks for trout rearing optimize water conservation by recirculating a portion of the effluent while maintaining steady oxygen levels and waste removal. Closed loop systems enhance biosecurity and water quality by continuously filtering and reconditioning water, reducing pathogen risks and environmental discharge compared to traditional flow-through setups.

Denitrification Reactor

Flow-through tanks for trout rearing require continuous water exchange, leading to higher ammonia levels that necessitate large-scale denitrification reactors to convert nitrate into nitrogen gas efficiently. Closed loop systems, by recirculating water and incorporating advanced denitrification reactors, optimize nitrogen removal, reduce water usage, and improve biosecurity in aquaculture operations.

Microbial Biofilter

Flow-through tanks for trout rearing rely on continuous water exchange, which limits microbial biofilter development and bacterial nutrient cycling, whereas closed loop systems promote stable microbial biofilm formation on biofilters, enhancing ammonia removal and maintaining optimal water quality. Efficient microbial biofilters in recirculating aquaculture systems (RAS) convert toxic nitrogenous wastes into less harmful compounds, reducing fish stress and improving growth performance in intensive trout farming.

Hydraulic Retention Time (HRT)

Flow-through tanks for trout rearing typically exhibit a lower hydraulic retention time (HRT), often ranging from minutes to hours, allowing continuous water exchange that supports high oxygen levels but increases water usage. Closed loop systems maintain significantly higher HRTs, sometimes exceeding days, enabling enhanced biofiltration and waste recycling while minimizing water consumption and environmental impact.

Super-Intensive Rearing

Super-intensive trout rearing in aquaculture benefits from closed loop systems due to their ability to maintain optimal water quality and temperature, significantly reducing disease risk compared to traditional flow-through tanks. Closed loop systems enhance biosecurity and resource efficiency by recycling water and minimizing environmental discharge, critical factors in sustainable high-density trout production.

Side-Stream Filtration

Side-stream filtration in flow-through tanks for trout rearing enhances water quality by continuously removing solids and contaminants, reducing stress and disease incidence. Closed loop systems leverage advanced side-stream filtration to recycle water efficiently, minimizing discharge and improving sustainability in intensive aquaculture operations.

Energy Balance Optimization

Flow-through tanks for trout rearing consume higher energy due to continuous water exchange and pumping, while closed loop systems optimize energy balance by recycling water through advanced filtration and oxygenation technologies. Implementing closed loop recirculating aquaculture systems (RAS) reduces water usage by up to 90% and lowers operational energy costs through improved heat retention and controlled environmental parameters.

Phosphorus Capture Technology

Flow-through tanks for trout rearing often result in higher phosphorus discharge, increasing the risk of eutrophication, whereas closed loop systems equipped with advanced phosphorus capture technology significantly reduce nutrient waste by recycling water and capturing phosphorus through biofiltration or chemical precipitation. Implementing closed loop systems enhances environmental sustainability and regulatory compliance by minimizing phosphorus effluent and promoting efficient nutrient management in aquaculture operations.

Flow-Through Tanks vs Closed Loop Systems for Trout Rearing Infographic

agridif.com

agridif.com