Brackishwater systems for tilapia cultivation offer enhanced growth rates and disease resistance due to optimal salinity levels, benefiting from the natural balance between freshwater and seawater. Freshwater systems provide greater control over water quality and temperature, resulting in consistent production cycles and easier management of nutrient levels. Both systems require careful monitoring of environmental parameters to maximize tilapia yield and ensure sustainable aquaculture practices.

Table of Comparison

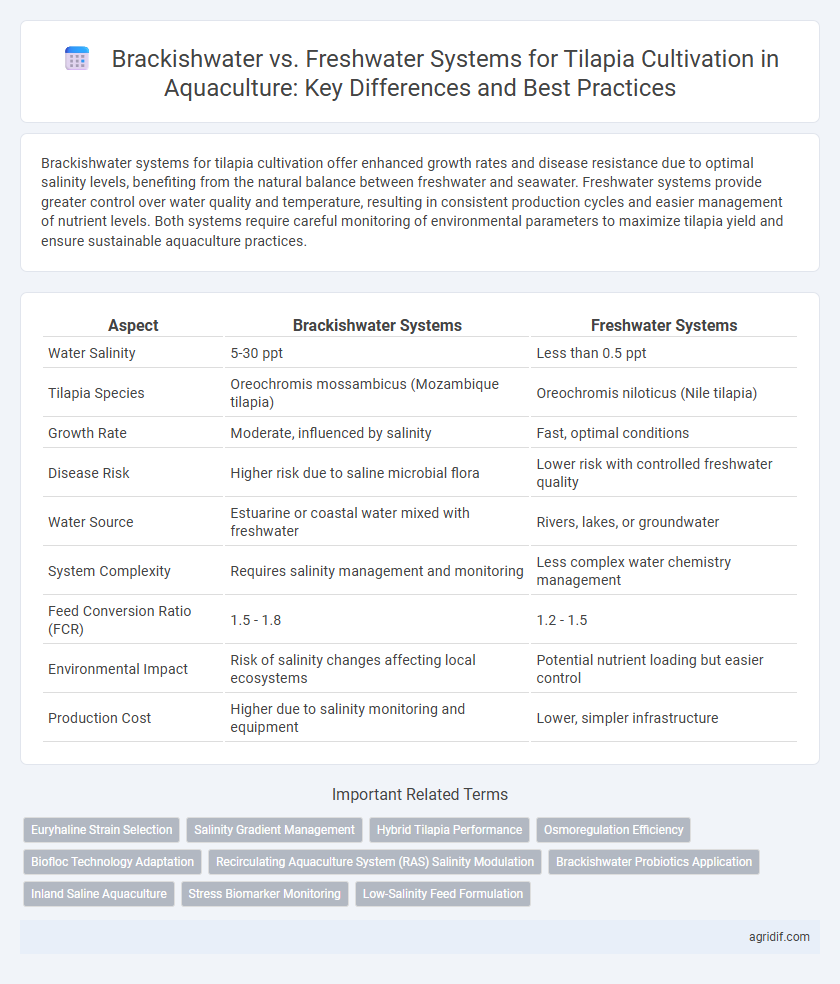

| Aspect | Brackishwater Systems | Freshwater Systems |

|---|---|---|

| Water Salinity | 5-30 ppt | Less than 0.5 ppt |

| Tilapia Species | Oreochromis mossambicus (Mozambique tilapia) | Oreochromis niloticus (Nile tilapia) |

| Growth Rate | Moderate, influenced by salinity | Fast, optimal conditions |

| Disease Risk | Higher risk due to saline microbial flora | Lower risk with controlled freshwater quality |

| Water Source | Estuarine or coastal water mixed with freshwater | Rivers, lakes, or groundwater |

| System Complexity | Requires salinity management and monitoring | Less complex water chemistry management |

| Feed Conversion Ratio (FCR) | 1.5 - 1.8 | 1.2 - 1.5 |

| Environmental Impact | Risk of salinity changes affecting local ecosystems | Potential nutrient loading but easier control |

| Production Cost | Higher due to salinity monitoring and equipment | Lower, simpler infrastructure |

Introduction to Tilapia Cultivation Systems

Tilapia cultivation thrives in both brackishwater and freshwater systems, each offering unique benefits for aquaculture efficiency. Brackishwater systems, with their intermediate salinity, enhance tilapia growth rates and disease resistance, making them suitable for coastal regions. Freshwater systems provide controlled environments with stable water quality, promoting scalable production and ease of management in inland areas.

Defining Brackishwater and Freshwater Environments

Brackishwater environments feature salinity levels between 0.5 to 30 parts per thousand, where freshwater mixes with seawater, creating ideal conditions for certain tilapia species adapted to moderate salt concentrations. Freshwater systems, characterized by salinity levels below 0.5 parts per thousand, provide stable habitats with low salt content suitable for tilapia varieties that thrive in non-saline waters. Understanding these specific salinity ranges is crucial for optimizing tilapia growth, health, and yield in aquaculture operations.

Water Quality Parameters: Brackish vs Freshwater

Brackishwater systems for tilapia cultivation typically exhibit higher salinity levels ranging from 5 to 15 ppt, which influence dissolved oxygen solubility and can affect fish osmoregulation differently than freshwater environments with near 0 ppt salinity. Water temperature stability and pH levels, usually between 7.5 and 8.5 in brackishwater, support optimal tilapia growth, whereas freshwater systems often maintain pH closer to neutral (6.5 to 7.5). Monitoring ammonia, nitrite, and nitrate concentrations is critical in both systems to prevent toxic accumulation, but the buffering capacity tends to be higher in brackishwater, mitigating rapid shifts in water chemistry.

Tilapia Species Suitability for Different Water Types

Tilapia species exhibit varying adaptability to brackishwater and freshwater systems, with Nile tilapia (Oreochromis niloticus) thriving predominantly in freshwater environments while Mozambique tilapia (Oreochromis mossambicus) shows higher tolerance to brackish conditions. Hybrid strains like the Genetically Improved Farmed Tilapia (GIFT) are optimized for freshwater cultivation due to their growth performance and disease resistance. Salinity levels influence osmoregulation, growth rates, and reproductive success, making species selection critical for sustainable tilapia aquaculture in diverse water types.

Comparative Growth Performance in Brackishwater and Freshwater

Tilapia cultivation exhibits varying growth performance between brackishwater and freshwater systems, with research indicating faster growth rates and higher weight gain in freshwater environments due to optimal temperature, dissolved oxygen, and lower salinity stress. Brackishwater systems, while offering potential for disease resistance and feed conversion efficiency, often show slower growth attributed to salinity fluctuations impacting metabolic processes. Comparative studies emphasize adjusting water quality parameters to maximize tilapia yield and growth rate, with freshwater systems currently favored for commercial scale production.

Feed and Nutritional Requirements in Each System

Brackishwater tilapia cultivation demands feed formulations with higher salt-tolerant protein sources and essential minerals to support osmotic regulation, contrasting with freshwater systems where nutritional requirements emphasize balanced carbohydrates and vitamins for optimal growth. The bioavailability of nutrients varies between the two environments, requiring tailored feed strategies that enhance feed conversion ratios and fish health in each system. Effective feed management in brackishwater and freshwater tilapia farming directly impacts growth performance, feed efficiency, and overall aquaculture sustainability.

Disease and Health Management: Key Differences

Brackishwater systems for tilapia cultivation present a unique microbial environment that often reduces the prevalence of freshwater-specific pathogens but can introduce salt-tolerant parasites and bacterial diseases requiring specialized health management protocols. Freshwater systems typically face challenges from pathogens such as Streptococcus agalactiae and Aeromonas hydrophila, necessitating vigilant water quality monitoring and frequent prophylactic treatments. Effective disease control in both systems relies on tailored biosecurity measures, vaccination programs, and stress reduction techniques to optimize fish health and minimize mortality rates.

Economic Viability and Market Considerations

Brackishwater tilapia cultivation often yields higher growth rates and better disease resistance, leading to increased economic viability through reduced mortality and faster turnover. Freshwater systems typically require lower initial investment and operational costs, making them accessible for small-scale farmers targeting local markets. Market considerations highlight stronger demand and premium pricing for brackishwater tilapia in export-oriented sectors, while freshwater tilapia remains dominant in domestic consumption due to its affordability and availability.

Environmental Impacts of Tilapia Production Systems

Brackishwater tilapia systems often lead to higher salinity discharge, which can alter local estuarine ecosystems and affect biodiversity, whereas freshwater systems primarily impact riverine and lake habitats through nutrient loading and eutrophication. Both systems contribute to water quality degradation due to the release of organic matter, antibiotics, and chemicals, but brackishwater cultivation carries more risk of mangrove destruction and soil salinization. Effective environmental management requires tailored mitigation strategies addressing specific ecological vulnerabilities in each production system to sustain biodiversity and water resources.

Choosing the Right System: Key Factors for Success

Tilapia cultivation requires careful selection between brackishwater and freshwater systems, as each environment impacts growth rates, disease resistance, and feed conversion efficiency differently. Brackishwater systems often provide higher salt tolerance and can reduce freshwater usage, whereas freshwater systems offer easier management and lower operational costs. Key factors for success include water quality parameters, salinity tolerance of the tilapia species, and local resource availability to optimize production and profitability.

Related Important Terms

Euryhaline Strain Selection

Euryhaline strain selection enhances tilapia cultivation by enabling optimal growth in both brackishwater and freshwater systems, improving salinity tolerance and overall productivity. Selecting robust euryhaline tilapia strains reduces mortality rates and increases feed conversion efficiency, driving sustainable aquaculture practices in diverse environmental conditions.

Salinity Gradient Management

Tilapia cultivation in brackishwater systems requires precise salinity gradient management to optimize growth rates and osmoregulatory balance, with salinity levels typically maintained between 5 to 15 ppt to enhance feed conversion ratios and stress tolerance. Freshwater systems maintain near-zero salinity, reducing operational complexity but often requiring more intensive water quality management to prevent disease outbreaks and ensure optimal dissolved oxygen levels.

Hybrid Tilapia Performance

Hybrid tilapia exhibit superior growth rates and greater disease resistance in brackishwater systems compared to freshwater environments, enhancing yield efficiency and feed conversion ratios. Brackishwater conditions also improve hybrid tilapia's osmoregulatory functions, promoting better stress tolerance and overall biomass production in aquaculture operations.

Osmoregulation Efficiency

Tilapia exhibit higher osmoregulation efficiency in brackishwater systems, allowing better ionic balance and reduced metabolic stress compared to freshwater environments. This enhanced osmoregulatory capacity improves growth rates and feed conversion efficiency, making brackishwater cultivation more suitable for optimizing tilapia production.

Biofloc Technology Adaptation

Biofloc technology enhances tilapia cultivation efficiency by promoting beneficial microbial growth in both brackishwater and freshwater systems, improving water quality and nutrient recycling. Freshwater systems generally exhibit better biofloc stability and higher tilapia growth rates due to lower salinity stress compared to brackishwater environments.

Recirculating Aquaculture System (RAS) Salinity Modulation

Recirculating Aquaculture Systems (RAS) for tilapia cultivation benefit from salinity modulation by optimizing water quality and fish health through controlled brackishwater or freshwater environments. Brackishwater RAS enhances osmoregulatory efficiency and growth rates in tilapia compared to freshwater systems, enabling precise salinity adjustments that improve feed conversion ratios and disease resistance.

Brackishwater Probiotics Application

Brackishwater systems for tilapia cultivation leverage probiotics to enhance water quality, boost fish health, and improve growth rates by balancing microbial communities and reducing pathogenic bacteria. This targeted application of brackishwater probiotics supports sustainable aquaculture by minimizing environmental stresses and optimizing nutrient absorption in tilapia compared to freshwater systems.

Inland Saline Aquaculture

Inland saline aquaculture leverages brackishwater systems, providing an optimal environment for tilapia cultivation by utilizing naturally occurring saline groundwater, which enhances growth rates and disease resistance compared to traditional freshwater systems. The controlled salinity levels in brackishwater systems improve feed conversion efficiency and reduce waterborne pathogens, making it a sustainable alternative for inland tilapia farming.

Stress Biomarker Monitoring

Brackishwater and freshwater systems for tilapia cultivation differ significantly in stress biomarker profiles, with brackishwater environments often inducing higher cortisol and glucose levels due to salinity fluctuations. Monitoring oxidative stress markers like superoxide dismutase (SOD) and malondialdehyde (MDA) provides critical insights into fish health, enabling optimized husbandry practices tailored to each system's specific stressors.

Low-Salinity Feed Formulation

Low-salinity feed formulation for tilapia cultivation in brackishwater systems requires higher mineral content and sodium levels compared to freshwater systems to support osmoregulation and enhance growth performance. Optimizing nutrient profiles with essential amino acids, vitamins, and trace elements tailored to the ionic environment improves feed efficiency and fish health in both brackishwater and freshwater tilapia farming.

Brackishwater vs Freshwater systems for tilapia cultivation Infographic

agridif.com

agridif.com