Biofloc Technology enhances shrimp production by promoting beneficial microbial communities that improve water quality and reduce the need for water exchange, leading to sustainable and cost-effective farming. In contrast, the Clear Water System relies on frequent water replacement and filtration to maintain water quality, often increasing operational costs and environmental impact. Biofloc offers improved feed conversion ratios and disease resistance, making it a more efficient alternative for commercial shrimp aquaculture.

Table of Comparison

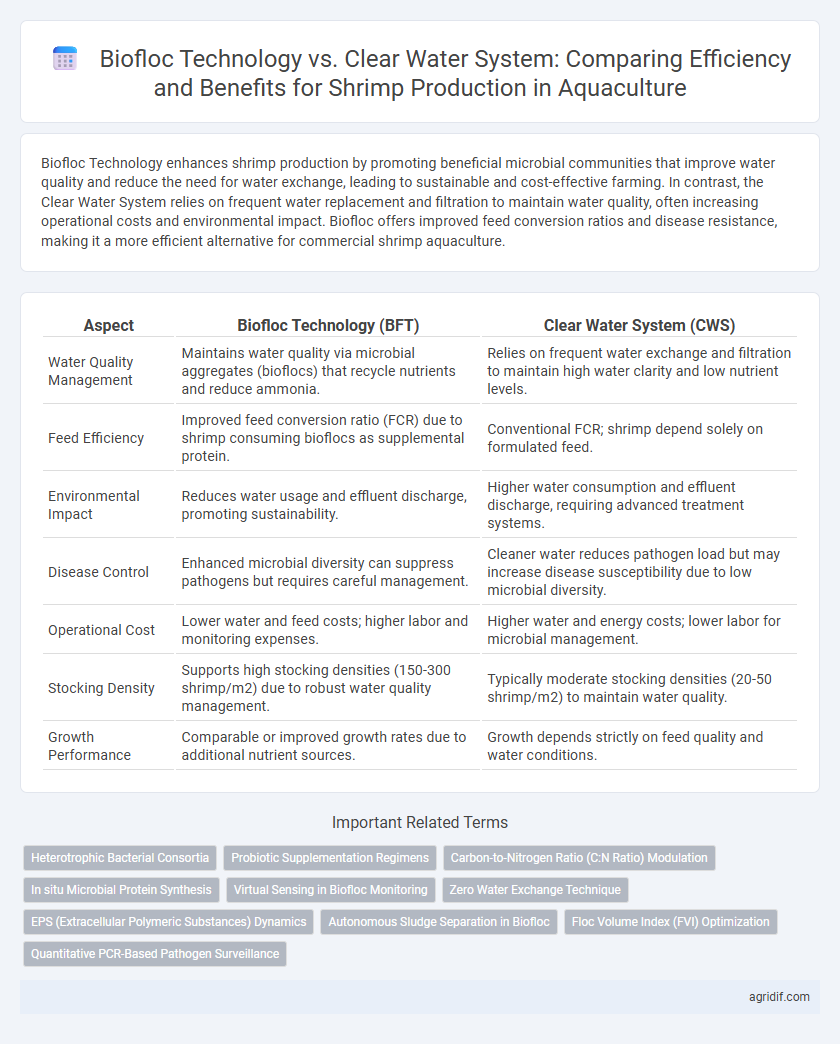

| Aspect | Biofloc Technology (BFT) | Clear Water System (CWS) |

|---|---|---|

| Water Quality Management | Maintains water quality via microbial aggregates (bioflocs) that recycle nutrients and reduce ammonia. | Relies on frequent water exchange and filtration to maintain high water clarity and low nutrient levels. |

| Feed Efficiency | Improved feed conversion ratio (FCR) due to shrimp consuming bioflocs as supplemental protein. | Conventional FCR; shrimp depend solely on formulated feed. |

| Environmental Impact | Reduces water usage and effluent discharge, promoting sustainability. | Higher water consumption and effluent discharge, requiring advanced treatment systems. |

| Disease Control | Enhanced microbial diversity can suppress pathogens but requires careful management. | Cleaner water reduces pathogen load but may increase disease susceptibility due to low microbial diversity. |

| Operational Cost | Lower water and feed costs; higher labor and monitoring expenses. | Higher water and energy costs; lower labor for microbial management. |

| Stocking Density | Supports high stocking densities (150-300 shrimp/m2) due to robust water quality management. | Typically moderate stocking densities (20-50 shrimp/m2) to maintain water quality. |

| Growth Performance | Comparable or improved growth rates due to additional nutrient sources. | Growth depends strictly on feed quality and water conditions. |

Introduction to Shrimp Aquaculture Systems

Shrimp aquaculture primarily utilizes Biofloc Technology (BFT) and Clear Water Systems (CWS) to optimize production in controlled environments. BFT enhances water quality by promoting beneficial microbial communities that recycle nutrients and reduce waste, increasing feed efficiency and sustainability. In contrast, CWS depends on frequent water exchange and filtration to maintain clarity and limits microbial activity, often resulting in higher operational costs and environmental impact.

Overview of Biofloc Technology in Shrimp Farming

Biofloc Technology (BFT) in shrimp farming enhances water quality by promoting beneficial microbial communities that convert waste nutrients into protein-rich bioflocs, serving as an additional feed source. This system reduces water exchange needs and improves shrimp survival rates, feed conversion ratios, and overall productivity compared to conventional Clear Water Systems (CWS). By maintaining a balanced carbon-to-nitrogen ratio and optimizing aeration, BFT supports sustainable aquaculture with lower environmental impact and operational costs.

Clear Water System: Principles and Practices

Clear Water System in shrimp production relies on maintaining optimal water quality through regular filtration, aeration, and controlled stocking densities to minimize waste accumulation and disease risk. This method emphasizes water exchange and biofiltration to keep parameters such as ammonia, nitrite, and dissolved oxygen within safe levels for shrimp health and growth. Advanced practices include using mechanical filters, UV sterilizers, and biofilters to sustain a stable aquatic environment, enhancing shrimp survival rates and productivity.

Key Differences Between Biofloc and Clear Water Systems

Biofloc technology in shrimp production harnesses microbial communities to convert waste into beneficial nutrients, reducing water exchange and enhancing biosecurity, whereas clear water systems rely on intensive filtration and frequent water replacement to maintain water quality. Biofloc systems promote natural feed availability and improve feed conversion ratios, contrasting with the higher dependency on formulated feeds in clear water systems. Energy consumption and operational costs are typically lower in biofloc systems due to reduced water treatment requirements, while clear water systems offer greater control over water parameters but demand more rigorous management and infrastructure.

Water Quality Management: Biofloc vs Clear Water

Biofloc Technology enhances water quality by promoting beneficial microbial communities that recycle nutrients, thereby reducing toxic ammonia and nitrite levels naturally. Clear Water Systems rely heavily on mechanical filtration and water exchange to maintain low concentrations of harmful substances but require significant energy and water resources. Biofloc minimizes water exchange and improves sustainability, whereas Clear Water demands continual monitoring and treatment to prevent water quality degradation in shrimp production.

Growth Performance and Survival Rates

Biofloc Technology enhances shrimp growth performance by promoting a balanced microbial environment that improves water quality and provides supplemental nutrition, leading to higher weight gain and feed conversion ratios compared to Clear Water Systems. Survival rates in shrimp cultured with Biofloc are significantly increased due to reduced pathogen loads and enhanced immune responses, whereas Clear Water Systems often require frequent water exchange and chemical treatments that can stress shrimp. Studies show Biofloc consistently yields survival rates above 85%, outperforming Clear Water Systems that typically achieve 70-80% under similar farming conditions.

Economic Considerations and Cost Efficiency

Biofloc Technology (BFT) significantly reduces feed costs by recycling waste into microbial protein, enhancing shrimp growth and survival rates, which lowers overall production expenses. In contrast, the Clear Water System (CWS) demands higher water exchange and filtration costs, increasing operational expenditures. Economic analyses reveal BFT offers greater cost efficiency through improved feed conversion ratios and reduced water treatment investments, making it a more profitable choice for shrimp farmers.

Environmental Impact and Sustainability

Biofloc Technology (BFT) enhances sustainability in shrimp production by recycling waste nutrients into microbial biomass, significantly reducing water exchange and minimizing environmental pollution. In contrast, the Clear Water System (CWS) demands high water usage and frequent effluent discharge, leading to greater ecological disturbance and potential eutrophication in surrounding aquatic ecosystems. BFT's closed-loop approach supports resource efficiency and lower carbon footprint, positioning it as a more environmentally sustainable method for intensive aquaculture.

Disease Control and Shrimp Health

Biofloc Technology enhances shrimp health by promoting beneficial microbial communities that suppress pathogens, reducing disease outbreaks compared to the Clear Water System. In shrimp production, biofloc's continuous water recirculation and nutrient recycling improve water quality, lowering stress and enhancing immune response. Conversely, the Clear Water System requires frequent water exchange and chemical treatments to control disease, potentially increasing shrimp vulnerability and operational costs.

Future Prospects and Recommendations

Biofloc Technology (BFT) offers sustainable future prospects for shrimp production by enhancing water quality and reducing feed costs through microbial nutrient recycling. In contrast, the Clear Water System (CWS) relies heavily on water exchange and stringent filtration, posing higher operational costs and environmental risks. Integrating BFT with precision monitoring and adaptive management is recommended to optimize shrimp health and productivity in future aquaculture practices.

Related Important Terms

Heterotrophic Bacterial Consortia

Biofloc Technology leverages heterotrophic bacterial consortia to convert organic waste into microbial biomass, enhancing water quality and providing a natural supplemental feed for shrimp, which improves growth rates and reduces feed costs. In contrast, the Clear Water System relies on frequent water exchange and limited microbial activity, often resulting in higher operational costs and increased vulnerability to waterborne diseases in shrimp production.

Probiotic Supplementation Regimens

Biofloc Technology enhances shrimp production by leveraging probiotic supplementation that promotes beneficial microbial communities, improving water quality and disease resistance. In contrast, Clear Water Systems rely heavily on external probiotic additions to maintain microbial balance, often requiring frequent dosing to sustain optimal shrimp health.

Carbon-to-Nitrogen Ratio (C:N Ratio) Modulation

Biofloc technology enhances shrimp production by maintaining an optimal Carbon-to-Nitrogen (C:N) ratio, promoting beneficial microbial growth that converts nitrogenous waste into protein-rich biomass, thereby reducing water exchange and improving water quality. In contrast, the Clear Water System relies on frequent water renewal to control nitrogen levels, making it less efficient in C:N ratio modulation and increasing operational costs.

In situ Microbial Protein Synthesis

Biofloc Technology enhances shrimp production by promoting in situ microbial protein synthesis, which converts waste nutrients into high-quality microbial biomass, reducing feed costs and improving water quality. In contrast, the Clear Water System relies on external feed inputs and frequent water exchange, leading to less efficient nutrient utilization and higher operational costs.

Virtual Sensing in Biofloc Monitoring

Virtual sensing in Biofloc Technology enables real-time monitoring of water quality parameters such as ammonia, nitrite, and dissolved oxygen, enhancing shrimp health and productivity compared to traditional Clear Water Systems. This digital approach optimizes biofloc dynamics by providing continuous data for timely management decisions, reducing reliance on manual sampling and improving sustainability in shrimp aquaculture.

Zero Water Exchange Technique

Biofloc Technology enhances shrimp production by maintaining water quality through microbial aggregation, enabling a zero water exchange system that reduces water consumption and improves biosecurity. In contrast, the Clear Water System relies on frequent water exchange to control waste and disease, leading to higher resource use and environmental impact.

EPS (Extracellular Polymeric Substances) Dynamics

Biofloc Technology enhances shrimp production by promoting EPS (Extracellular Polymeric Substances) dynamics that improve water quality and microbial balance, fostering disease resistance and nutrient recycling. In contrast, the Clear Water System relies on frequent water exchange, limiting EPS development and thus reducing the natural biofilm benefits integral to shrimp health and growth.

Autonomous Sludge Separation in Biofloc

Biofloc technology enhances shrimp production by promoting autonomous sludge separation through microbial aggregation, reducing labor and water exchange compared to the Clear Water System, which relies heavily on mechanical filtration for sludge removal. This natural biofloc aggregation improves water quality and nutrient recycling, boosting shrimp growth and overall system sustainability.

Floc Volume Index (FVI) Optimization

Optimizing Floc Volume Index (FVI) in Biofloc Technology enhances nutrient recycling and microbial balance, leading to improved shrimp health and growth rates compared to the Clear Water System. Maintaining an ideal FVI range of 5-15 ml/l promotes water quality stability and reduces feed costs, making Biofloc systems more sustainable and economically viable for intensive shrimp production.

Quantitative PCR-Based Pathogen Surveillance

Quantitative PCR-based pathogen surveillance in biofloc technology significantly enhances early detection and management of pathogenic Vibrio species in shrimp production compared to the clear water system, resulting in a 30-40% reduction in disease outbreaks. Biofloc systems offer integrated microbial management by promoting beneficial microbial communities, which improve shrimp survival rates by 15-25% relative to the traditional clear water approach.

Biofloc Technology vs Clear Water System for Shrimp Production Infographic

agridif.com

agridif.com