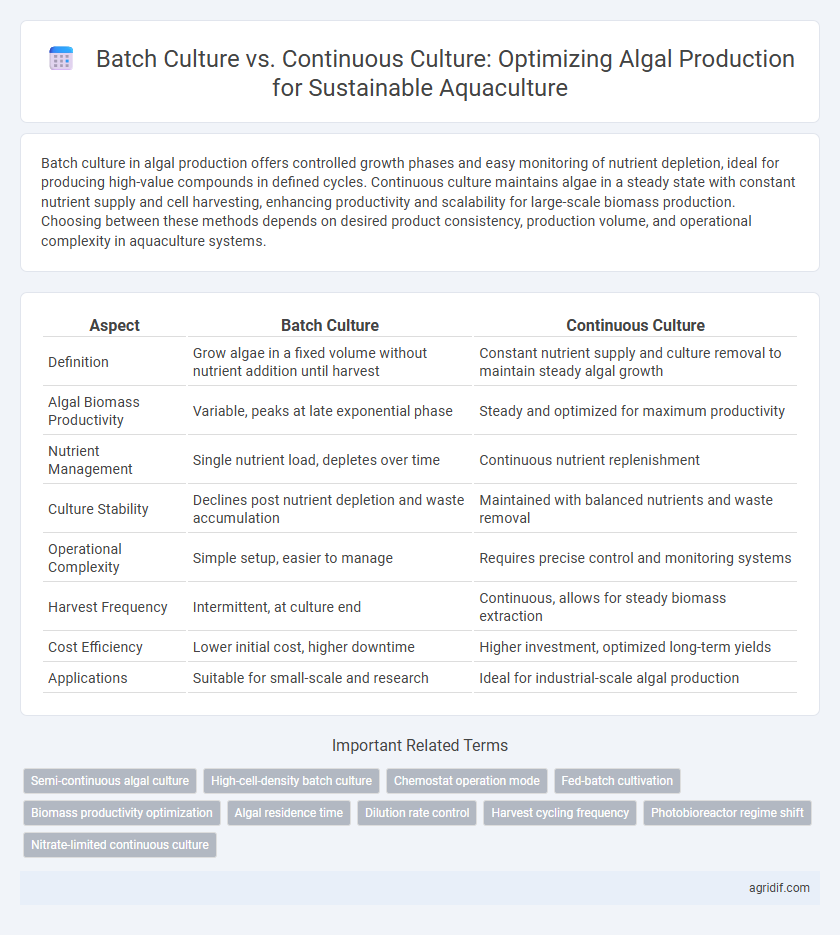

Batch culture in algal production offers controlled growth phases and easy monitoring of nutrient depletion, ideal for producing high-value compounds in defined cycles. Continuous culture maintains algae in a steady state with constant nutrient supply and cell harvesting, enhancing productivity and scalability for large-scale biomass production. Choosing between these methods depends on desired product consistency, production volume, and operational complexity in aquaculture systems.

Table of Comparison

| Aspect | Batch Culture | Continuous Culture |

|---|---|---|

| Definition | Grow algae in a fixed volume without nutrient addition until harvest | Constant nutrient supply and culture removal to maintain steady algal growth |

| Algal Biomass Productivity | Variable, peaks at late exponential phase | Steady and optimized for maximum productivity |

| Nutrient Management | Single nutrient load, depletes over time | Continuous nutrient replenishment |

| Culture Stability | Declines post nutrient depletion and waste accumulation | Maintained with balanced nutrients and waste removal |

| Operational Complexity | Simple setup, easier to manage | Requires precise control and monitoring systems |

| Harvest Frequency | Intermittent, at culture end | Continuous, allows for steady biomass extraction |

| Cost Efficiency | Lower initial cost, higher downtime | Higher investment, optimized long-term yields |

| Applications | Suitable for small-scale and research | Ideal for industrial-scale algal production |

Introduction to Algal Production Systems

Batch culture in algal production involves growing algae in a closed system with a fixed volume of nutrient medium, allowing cells to proliferate until nutrients are depleted. Continuous culture maintains a steady state by constantly supplying fresh nutrients and removing culture, optimizing algal biomass yield and nutrient utilization over time. Understanding the operational differences between batch and continuous cultures is crucial for selecting efficient algal production systems tailored to specific biomass quality and quantity requirements.

Defining Batch Culture in Algae Farming

Batch culture in algal production involves cultivating algae in a closed system where nutrients are supplied at the beginning and no additional inputs occur until harvest. This method allows precise control over growth phases, maximizing biomass accumulation during optimal conditions. Batch culture is favored for producing specific algal compounds due to its capacity to limit contamination and maintain stable environmental parameters throughout the growth cycle.

Understanding Continuous Culture in Aquaculture

Continuous culture in aquaculture involves maintaining algal production at a steady state by constantly supplying fresh nutrients and removing a portion of the culture, ensuring optimal growth conditions and biomass yield. This method enhances productivity by minimizing growth lag phases and stabilizing environmental parameters such as light, pH, and nutrient concentration. Continuous culture systems are particularly advantageous for large-scale algal biomass production due to their efficiency and ability to provide a consistent output for downstream aquaculture applications.

Key Differences Between Batch and Continuous Culture

Batch culture in algal production involves cultivating algae in a closed system where nutrients are supplied at the start and the entire culture is harvested at the end, leading to distinct growth phases and nutrient depletion over time. Continuous culture maintains a steady-state environment by constantly adding fresh nutrients and removing culture medium, enabling sustained algal growth and consistent biomass productivity. Key differences include nutrient availability, growth dynamics, and operational complexity, with batch culture allowing easier control over growth phases while continuous culture optimizes production efficiency and resource utilization.

Advantages of Batch Culture for Algal Production

Batch culture for algal production offers greater control over growth conditions, enabling precise manipulation of nutrient levels and light exposure to optimize biomass yield. It allows for easy monitoring and harvesting at peak productivity phases, reducing contamination risks and ensuring consistent product quality. This method also provides flexibility for producing diverse algal strains by adjusting batch parameters according to specific culture requirements.

Benefits of Continuous Culture Techniques

Continuous culture techniques in algal production enable consistent biomass yield by maintaining optimal growth conditions, thereby enhancing productivity compared to batch culture. This method allows precise control of nutrient supply, light intensity, and waste removal, resulting in higher cell density and improved resource efficiency. The scalability and automation potential of continuous culture reduce downtime and operational costs, making it ideal for large-scale aquaculture applications.

Limitations and Challenges in Batch Cultures

Batch culture in algal production faces limitations such as nutrient depletion and accumulation of waste products, which can inhibit growth and reduce yield. The process requires downtime for harvesting and cleaning, leading to inconsistent biomass output and increased labor costs. Additionally, batch cultures often struggle with scale-up challenges and limited control over environmental parameters, impacting overall productivity and efficiency.

Drawbacks of Continuous Culture Systems

Continuous culture systems for algal production in aquaculture face drawbacks such as increased susceptibility to contamination due to prolonged cultivation periods and constant nutrient supply. Maintaining optimal growth conditions is challenging, leading to potential fluctuations in algal biomass quality and productivity. Additionally, high operational costs and complex monitoring requirements hinder scalability and economic efficiency compared to batch culture systems.

Choosing the Right Culture Method for Your Aquafarm

Selecting between batch culture and continuous culture for algal production depends on your aquafarm's specific goals and operational capacity. Batch culture offers simplicity and control, ideal for small-scale or seasonal production with easier contamination management. Continuous culture supports consistent biomass output and higher productivity but requires advanced monitoring systems and greater investment in infrastructure.

Future Trends in Algal Cultivation Technologies

Batch culture in algal production offers controlled growth environments ideal for experimental and high-quality biomass, while continuous culture systems maximize yield and resource efficiency through steady-state operations. Future trends in algal cultivation technologies emphasize integrating advanced photobioreactors with real-time monitoring sensors and automated nutrient delivery, enhancing productivity and sustainability. Innovations like artificial intelligence-driven optimization and hybrid culture systems are expected to revolutionize large-scale algal biomass production for biofuels, food supplements, and bioplastics.

Related Important Terms

Semi-continuous algal culture

Semi-continuous algal culture in aquaculture combines the benefits of batch and continuous systems by periodically harvesting a portion of the biomass while maintaining culture volume and nutrient levels, optimizing growth rates and biomass yield. This method enhances productivity and stability in algal production, reducing contamination risks and nutrient depletion compared to purely continuous culture.

High-cell-density batch culture

High-cell-density batch culture in algal production offers precise control over nutrient supply and growth phases, enabling maximum biomass accumulation and enhanced metabolite yield compared to continuous culture systems. This method facilitates optimization of harvest timing and reduces contamination risks, improving overall productivity in aquaculture operations.

Chemostat operation mode

Batch culture in algal production involves growing algae in a closed system with limited nutrients, leading to nutrient depletion and reduced growth over time; in contrast, continuous culture using a chemostat maintains steady-state conditions by constantly supplying fresh medium and removing culture, optimizing growth rate and biomass productivity. Chemostat operation enables precise control of growth parameters such as dilution rate and nutrient concentration, enhancing metabolic stability and maximizing algal yield for aquaculture applications.

Fed-batch cultivation

Fed-batch cultivation in algal production offers controlled nutrient addition, enhancing biomass yield and preventing substrate inhibition compared to batch culture. This method maintains optimal growth conditions by intermittently feeding nutrients, balancing productivity and resource efficiency more effectively than continuous culture.

Biomass productivity optimization

Batch culture in algal aquaculture allows for controlled nutrient dosing and light exposure, resulting in high biomass productivity during specific growth phases; continuous culture maintains steady-state conditions that optimize resource utilization and sustain consistent biomass yield over time. Optimizing biomass productivity involves balancing nutrient supply, light intensity, and dilution rates, with continuous culture generally providing greater efficiency for large-scale algal biomass production.

Algal residence time

Batch culture in algal production involves fixed residence times, typically ranging from several days to weeks, allowing controlled nutrient consumption and biomass accumulation, whereas continuous culture maintains a steady state with shorter algal residence times to optimize productivity and sustain nutrient uptake. Managing algal residence time in continuous culture enhances growth rates and prevents cell senescence, while batch culture's extended residence supports metabolite accumulation but risks nutrient depletion and growth inhibition.

Dilution rate control

Batch culture for algal production involves fixed nutrient conditions and no medium replacement during growth, limiting dilution rate control to the initial setup and leading to variable growth phases. Continuous culture maintains steady-state growth by controlling dilution rates through constant nutrient input and biomass removal, optimizing algal productivity and stability in aquaculture systems.

Harvest cycling frequency

Batch culture in algal production involves periodic harvesting, often every 7-14 days, allowing for complete biomass accumulation before reset, maximizing product quality but limiting overall yield frequency. Continuous culture maintains steady-state conditions with daily or more frequent harvests, enhancing productivity and consistent biomass output, though it requires more complex management to balance nutrient supply and waste removal.

Photobioreactor regime shift

Batch culture in algal photobioreactors offers controlled nutrient provision and simplified harvest cycles, optimizing biomass yield for specific production phases, while continuous culture enables steady-state operation with constant nutrient supply and cell density, enhancing productivity and reducing downtime. Shifting from batch to continuous photobioreactor regimes in aquaculture can improve algal growth rates and resource efficiency, promoting sustainable algal biomass production for biofuels and bioproducts.

Nitrate-limited continuous culture

Nitrate-limited continuous culture in algal production maintains steady-state growth by regulating nitrate concentrations, enhancing biomass productivity and nutrient utilization efficiency compared to batch culture methods. This approach reduces nutrient wastage and allows precise control over algal physiology, optimizing lipid accumulation and overall yield in aquaculture applications.

Batch Culture vs Continuous Culture for Algal Production Infographic

agridif.com

agridif.com