Controlled-release fertilizers enhance nutrient efficiency by releasing nutrients steadily, reducing losses and improving crop uptake compared to split applications that deliver nutrients in several doses. This method minimizes labor and application frequency while maintaining consistent nutrient availability throughout the growing season. Controlled-release fertilizers support sustainable crop production by optimizing nutrient use and decreasing environmental impact from leaching or runoff.

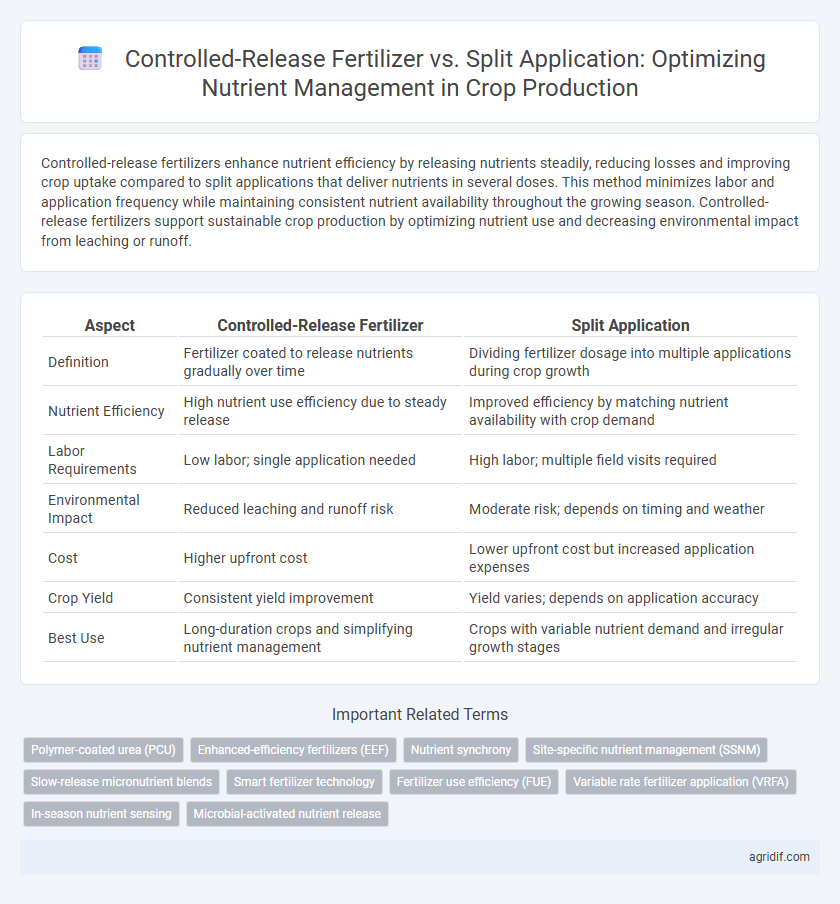

Table of Comparison

| Aspect | Controlled-Release Fertilizer | Split Application |

|---|---|---|

| Definition | Fertilizer coated to release nutrients gradually over time | Dividing fertilizer dosage into multiple applications during crop growth |

| Nutrient Efficiency | High nutrient use efficiency due to steady release | Improved efficiency by matching nutrient availability with crop demand |

| Labor Requirements | Low labor; single application needed | High labor; multiple field visits required |

| Environmental Impact | Reduced leaching and runoff risk | Moderate risk; depends on timing and weather |

| Cost | Higher upfront cost | Lower upfront cost but increased application expenses |

| Crop Yield | Consistent yield improvement | Yield varies; depends on application accuracy |

| Best Use | Long-duration crops and simplifying nutrient management | Crops with variable nutrient demand and irregular growth stages |

Introduction to Nutrient Management in Crop Production

Controlled-release fertilizers enhance nutrient use efficiency by releasing nutrients gradually in sync with crop nutrient uptake, reducing losses and environmental impact. Split application involves dividing fertilizer doses across key growth stages to match crop nutrient demand, minimizing leaching and volatilization. Both methods optimize nutrient availability, improving yield and sustainability in crop production systems.

Overview of Controlled-Release Fertilizers

Controlled-release fertilizers (CRFs) enhance nutrient use efficiency by releasing nutrients gradually over time, aligning with crop nutrient uptake patterns and minimizing leaching losses. These fertilizers typically consist of nutrient cores coated with polymers or sulfur, allowing precise control over the release rate based on environmental conditions such as temperature and moisture. Compared to split applications, CRFs reduce labor and application frequency while improving crop yield and environmental sustainability through optimized nutrient availability.

Understanding Split Fertilizer Application

Split fertilizer application enhances nutrient use efficiency by delivering fertilizers in multiple doses aligned with crop growth stages, reducing nutrient losses compared to single, uncontrolled releases. Controlled-release fertilizers provide a steady nutrient supply but may not perfectly match the dynamic nutrient demand throughout the crop cycle, potentially leading to suboptimal uptake. Understanding the timing and crop-specific nutrient requirements is crucial for optimizing split application schedules to maximize yield and minimize environmental impact.

Mechanisms of Nutrient Release in Controlled Products

Controlled-release fertilizers release nutrients gradually through polymer coatings or matrix systems that regulate nutrient dissolution based on soil temperature and moisture. This steady nutrient supply enhances plant uptake efficiency and reduces nutrient leaching compared to split applications, which rely on multiple, time-specific nutrient deliveries. The controlled mechanisms in these fertilizers optimize nutrient availability, aligning release rates with crop nutrient demand throughout growth stages.

Efficiency Comparison: Controlled-Release vs Split Application

Controlled-release fertilizers provide a steady nutrient supply, minimizing losses through leaching and volatilization, thereby enhancing nutrient use efficiency compared to split applications. Split application delivers nutrients at multiple growth stages but may increase labor costs and risk of uneven nutrient availability. Studies show controlled-release fertilizers improve crop yield and nutrient uptake consistency, making them a more efficient choice in nutrient management.

Impact on Crop Yield and Quality

Controlled-release fertilizers provide a steady nutrient supply, enhancing nutrient use efficiency, which leads to increased crop yield and improved quality by minimizing nutrient losses and reducing stress during critical growth stages. Split applications allow precise timing of nutrient availability, optimizing nutrient uptake and adjusting to crop demand fluctuations, resulting in enhanced yield consistency and grain quality. Studies show that controlled-release fertilizers often outperform split applications in long-term nitrogen availability, promoting sustained crop growth and higher-quality produce.

Environmental Implications and Sustainability

Controlled-release fertilizers minimize nutrient losses through leaching and volatilization, reducing environmental pollution and enhancing nutrient uptake efficiency compared to split application methods. Split applications often require multiple field passes, increasing fuel consumption and greenhouse gas emissions, whereas controlled-release fertilizers streamline application and promote sustainable farming practices. Adoption of controlled-release fertilizers supports long-term soil health and water quality by preventing nutrient runoff and maintaining balanced nutrient availability.

Cost Analysis and Economic Considerations

Controlled-release fertilizers often reduce labor costs and nutrient losses by providing nutrients steadily, enhancing crop yield stability and minimizing environmental impact compared to split applications. Split application demands multiple field operations, increasing application labor and machinery expenses, potentially elevating overall cost despite allowing targeted nutrient timing. Economic evaluations highlight that controlled-release options can improve cost-effectiveness by increasing nutrient use efficiency and reducing input frequency, whereas split applications offer flexibility but may incur higher cumulative operational costs.

Practical Guidelines for Farmers

Controlled-release fertilizers improve nutrient use efficiency by releasing nutrients gradually, reducing losses from leaching and volatilization compared to traditional split applications. Farmers should match the release rate of controlled-release fertilizers with crop nutrient demand stages to optimize growth and minimize environmental impact. Practical guidelines recommend soil testing before application and adjusting fertilizer type and amount based on specific crop requirements and local conditions.

Future Trends in Fertilizer Technology

Controlled-release fertilizers enhance nutrient use efficiency by releasing nutrients gradually, matching crop uptake patterns, thereby reducing leaching and environmental impact. Split application continues to be essential for optimizing nutrient availability at critical growth stages but may involve higher labor and management costs. Future trends in fertilizer technology emphasize integrating controlled-release formulations with precision agriculture and sensor-based nutrient management to optimize application timing and rates, ultimately improving crop yield and sustainability.

Related Important Terms

Polymer-coated urea (PCU)

Polymer-coated urea (PCU) enhances nutrient use efficiency by releasing nitrogen gradually, reducing leaching and volatilization compared to split application methods. Controlled-release fertilizers like PCU provide consistent nutrient availability, optimizing crop growth and yield while minimizing environmental impact in crop production systems.

Enhanced-efficiency fertilizers (EEF)

Enhanced-efficiency fertilizers (EEF), including controlled-release fertilizers, optimize nutrient availability by releasing nutrients gradually, reducing leaching and volatilization losses compared to traditional split application methods. Studies demonstrate that EEFs improve nutrient use efficiency, enhance crop yields, and minimize environmental impacts by aligning nutrient release with crop uptake patterns.

Nutrient synchrony

Controlled-release fertilizers enhance nutrient synchrony by gradually releasing nutrients in alignment with crop uptake, reducing losses and improving efficiency. Split application also targets nutrient synchrony by timing fertilizer inputs according to crop growth stages, but controlled-release fertilizers simplify management and minimize labor requirements.

Site-specific nutrient management (SSNM)

Controlled-release fertilizers enhance nutrient availability by synchronizing nutrient release with crop demand, reducing losses and improving efficiency in site-specific nutrient management (SSNM) systems. Split application, by applying nutrients at critical growth stages based on soil and crop monitoring, allows precise nutrient targeting, minimizing environmental impact and supporting optimal crop production in SSNM.

Slow-release micronutrient blends

Slow-release micronutrient blends in controlled-release fertilizers enhance nutrient availability over extended periods, improving crop uptake efficiency compared to split applications that require multiple dosing and risk nutrient loss. These blends optimize nutrient use, reduce leaching, and support sustained plant growth by delivering essential micronutrients steadily during critical growth stages.

Smart fertilizer technology

Controlled-release fertilizers enhance nutrient use efficiency by releasing nutrients gradually, aligning with crop uptake patterns, which reduces leaching and environmental impact compared to traditional split application methods. Smart fertilizer technology integrates sensors and data analytics to optimize nutrient timing and dosage, further improving crop yield and sustainability in nutrient management.

Fertilizer use efficiency (FUE)

Controlled-release fertilizers enhance Fertilizer Use Efficiency (FUE) by minimizing nutrient losses through synchronized nutrient release with crop demand, reducing leaching and volatilization compared to split application methods. Split application provides timely nutrient availability but may result in higher nutrient losses and inconsistent FUE due to environmental factors affecting nutrient uptake.

Variable rate fertilizer application (VRFA)

Variable rate fertilizer application (VRFA) enhances nutrient efficiency by tailoring fertilizer placement and timing to crop-specific needs, outperforming traditional controlled-release fertilizers and split applications in maximizing nutrient uptake and minimizing environmental impact. VRFA integrates precision technology to adjust nutrient delivery dynamically, optimizing crop yield and reducing fertilizer waste across variable field conditions.

In-season nutrient sensing

Controlled-release fertilizers provide a steady nutrient supply, reducing leaching and improving nutrient use efficiency, while split application aligns nutrient delivery more precisely with crop uptake based on in-season nutrient sensing data. Advances in in-season nutrient sensing technologies enable real-time monitoring of crop nutrient status, optimizing the timing and amount of fertilizer applied through split applications for enhanced yield and sustainability.

Microbial-activated nutrient release

Controlled-release fertilizers enhance nutrient availability by promoting microbial-activated nutrient release, optimizing soil microbiome activity and extending nutrient release over time. Split application improves nutrient use efficiency by synchronizing nutrient delivery with crop demand, but controlled-release fertilizers provide a more consistent microbial stimulation and reduced leaching losses in diverse soil environments.

Controlled-release fertilizer vs split application for nutrient management Infographic

agridif.com

agridif.com