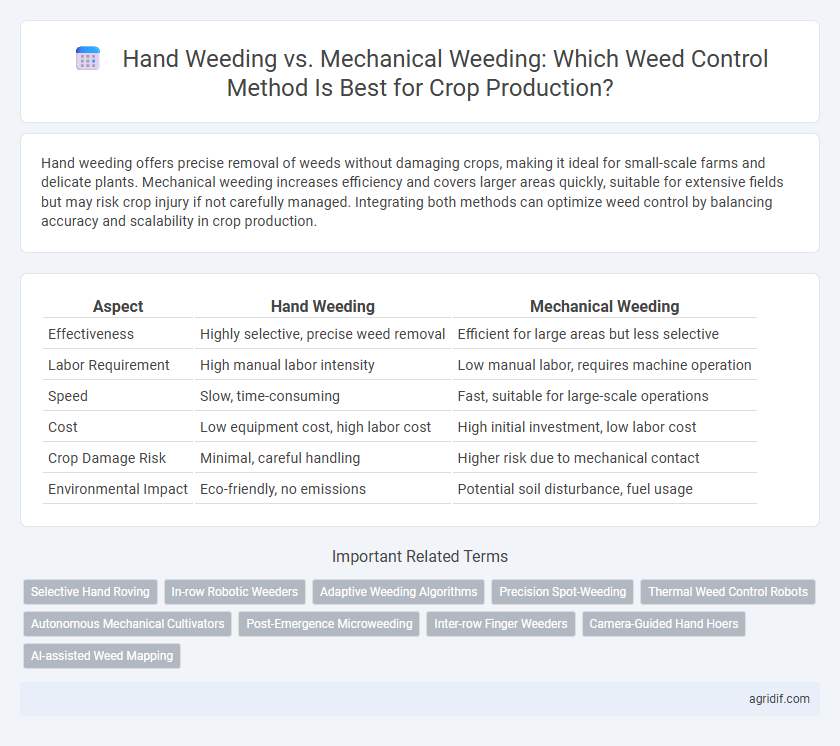

Hand weeding offers precise removal of weeds without damaging crops, making it ideal for small-scale farms and delicate plants. Mechanical weeding increases efficiency and covers larger areas quickly, suitable for extensive fields but may risk crop injury if not carefully managed. Integrating both methods can optimize weed control by balancing accuracy and scalability in crop production.

Table of Comparison

| Aspect | Hand Weeding | Mechanical Weeding |

|---|---|---|

| Effectiveness | Highly selective, precise weed removal | Efficient for large areas but less selective |

| Labor Requirement | High manual labor intensity | Low manual labor, requires machine operation |

| Speed | Slow, time-consuming | Fast, suitable for large-scale operations |

| Cost | Low equipment cost, high labor cost | High initial investment, low labor cost |

| Crop Damage Risk | Minimal, careful handling | Higher risk due to mechanical contact |

| Environmental Impact | Eco-friendly, no emissions | Potential soil disturbance, fuel usage |

Introduction to Weed Control in Crop Production

Weed control is a critical component of crop production, directly impacting crop yield and quality by reducing competition for nutrients, water, and sunlight. Hand weeding offers precise removal of weeds, especially in small-scale or sensitive crop systems, but is labor-intensive and time-consuming. Mechanical weeding, using tools such as hoes, cultivators, or automated machines, provides faster and more scalable weed control but may cause soil disturbance and damage to crops if not carefully managed.

Overview of Hand Weeding Methods

Hand weeding involves manually removing weeds from crops using tools such as hoes, knives, or by hand pulling, which allows for precise targeting of unwanted plants without damaging the crop. This method is labor-intensive but effective in small-scale or organic farming systems where herbicide use is limited or avoided. Hand weeding also facilitates early detection of pest or disease issues, contributing to improved crop health and yield.

Mechanical Weeding: Tools and Techniques

Mechanical weeding employs advanced tools such as rotary hoes, tine weeders, and cultivators to efficiently disrupt weed growth while minimizing crop damage. Precision-guided machinery equipped with GPS and AI technology enhances accuracy, targeting weeds with minimal soil disturbance and reducing herbicide dependency. These techniques improve soil aeration and contribute to sustainable crop production by promoting healthier root development and increasing overall yield.

Effectiveness of Hand vs Mechanical Weeding

Hand weeding offers precise control by targeting individual weeds, minimizing crop damage and ensuring thorough removal, which is especially effective in small-scale or sensitive crops. Mechanical weeding covers larger areas faster, significantly reducing labor costs and time, but may miss some weeds and cause soil disturbance that can affect crop health. Combining both methods can optimize weed control effectiveness by leveraging the precision of hand weeding with the efficiency of mechanical tools.

Labor and Cost Considerations

Hand weeding requires intensive labor and is often more time-consuming, making it costly for large-scale crop production. Mechanical weeding reduces labor needs and increases efficiency but involves higher initial investment in equipment and maintenance. Cost-effectiveness depends on farm size, labor availability, and long-term operational expenses associated with each method.

Impact on Crop Yield and Quality

Hand weeding provides precise removal of weeds, minimizing crop damage and often leading to higher crop quality and yield in small-scale farming. Mechanical weeding offers faster weed control over large areas but can cause crop injury and soil disruption, potentially reducing yield and quality if not carefully managed. Effective weed management balances the accuracy of hand weeding with the efficiency of mechanical methods to optimize both crop yield and quality.

Environmental Implications of Weed Control Methods

Hand weeding minimizes soil disruption and preserves beneficial microorganisms, reducing carbon footprint compared to fossil-fuel-powered mechanical weeding equipment. Mechanical weeding often leads to increased soil compaction and erosion, adversely affecting soil health and water retention capabilities. Sustainable crop production prioritizes weed control methods that balance efficacy with ecological impact to maintain long-term environmental quality.

Suitability for Different Crop Types and Field Sizes

Hand weeding offers precise control for delicate or small-scale crops like vegetables and horticultural plants, especially in small field sizes where selective weed removal is crucial. Mechanical weeding is more efficient for larger fields and row crops such as cereals and legumes, providing rapid weed management but with less selectivity, which may risk crop damage. Choosing between hand and mechanical weeding depends on crop sensitivity, field size, and labor availability to optimize weed control and crop yield.

Challenges and Limitations of Each Method

Hand weeding ensures precise removal of weeds but is labor-intensive, time-consuming, and costly, limiting scalability for large-scale crop production. Mechanical weeding offers faster weed control and reduces labor demands but can cause crop damage, is less effective for weeds near plants, and requires regular equipment maintenance. Both methods face challenges in adapting to diverse field conditions and weed species, impacting overall efficiency and crop yield.

Future Trends in Weed Management Practices

Future trends in weed management practices highlight increased adoption of precision agriculture technologies that integrate mechanical weeding with AI-driven weed detection systems to enhance efficiency and reduce herbicide use. Innovations such as autonomous robotic weeders and sensor-based equipment are expected to minimize labor costs associated with hand weeding while improving crop yields by targeting weeds more accurately. Advances in machine learning and robotics will drive the shift toward sustainable, environmentally friendly weed control methods in large-scale crop production.

Related Important Terms

Selective Hand Roving

Selective hand roving in crop production targets specific weeds by manual removal, minimizing crop damage and promoting better plant health compared to mechanical weeding, which often disrupts soil structure and non-target plants. This precision method enhances weed control efficiency, particularly in high-value or sensitive crops, leading to increased yield and reduced herbicide dependence.

In-row Robotic Weeders

In-row robotic weeders significantly enhance crop production by precisely targeting weeds within crop rows, reducing herbicide reliance and labor costs compared to traditional hand weeding and mechanical methods. Advanced sensor technologies and AI algorithms enable these robotic systems to distinguish crops from weeds, improving weed control efficiency and promoting sustainable agricultural practices.

Adaptive Weeding Algorithms

Adaptive weeding algorithms enhance mechanical weeding efficiency by using real-time data and machine learning to precisely identify and target weed species, reducing crop damage and minimizing herbicide use. These innovations outperform traditional hand weeding by offering scalable, cost-effective, and eco-friendly solutions that optimize weed control in diverse cropping systems.

Precision Spot-Weeding

Precision spot-weeding uses advanced sensors and robotics to target individual weeds, significantly reducing herbicide use and crop damage compared to traditional hand weeding. This technology enhances efficiency and accuracy in weed control, leading to higher crop yields and sustainable production practices.

Thermal Weed Control Robots

Thermal weed control robots offer precise, chemical-free weed management by applying targeted heat to eliminate weeds without damaging crops, enhancing sustainable crop production. Compared to traditional hand weeding or mechanical weeding, these robots reduce labor costs and soil disturbance while improving efficiency and crop yield.

Autonomous Mechanical Cultivators

Autonomous mechanical cultivators leverage advanced sensor technology and AI algorithms to precisely target weeds, significantly reducing labor costs and minimizing crop damage compared to traditional hand weeding. These systems enhance efficiency by operating continuously and adapting to varying field conditions, thereby improving overall weed control and crop yield.

Post-Emergence Microweeding

Post-emergence microweeding effectively targets young weed seedlings, reducing competition and enhancing crop growth while minimizing soil disturbance compared to mechanical weeding. This precise method improves weed control efficiency and preserves soil structure, promoting higher crop yields and sustainable crop production practices.

Inter-row Finger Weeders

Inter-row finger weeders provide precise mechanical weed control by targeting weeds between crop rows without damaging the plants, enhancing soil aeration and reducing labor costs compared to hand weeding. This method increases efficiency in weed management while promoting sustainable crop production through decreased herbicide reliance.

Camera-Guided Hand Hoers

Camera-guided hand hoers enhance precision in hand weeding by using advanced sensor technology to identify and target weeds directly, minimizing crop damage and optimizing labor efficiency. This method outperforms traditional mechanical weeding by reducing soil disturbance and conserving beneficial microorganisms essential for sustainable crop production.

AI-assisted Weed Mapping

AI-assisted weed mapping enhances mechanical weeding precision by accurately identifying weed-infested areas, reducing crop damage and labor costs compared to traditional hand weeding. This technology enables targeted herbicide application and optimizes resource use, leading to higher crop yields and sustainable weed management.

Hand Weeding vs Mechanical Weeding for Weed Control Infographic

agridif.com

agridif.com