Mechanical harvesting significantly increases efficiency and reduces labor costs compared to manual harvesting, enabling faster crop extraction on large-scale farms. However, manual harvesting allows for more selective picking, which can minimize crop damage and improve quality in delicate or specialty crops. Balancing these methods depends on crop type, farm size, and economic considerations.

Table of Comparison

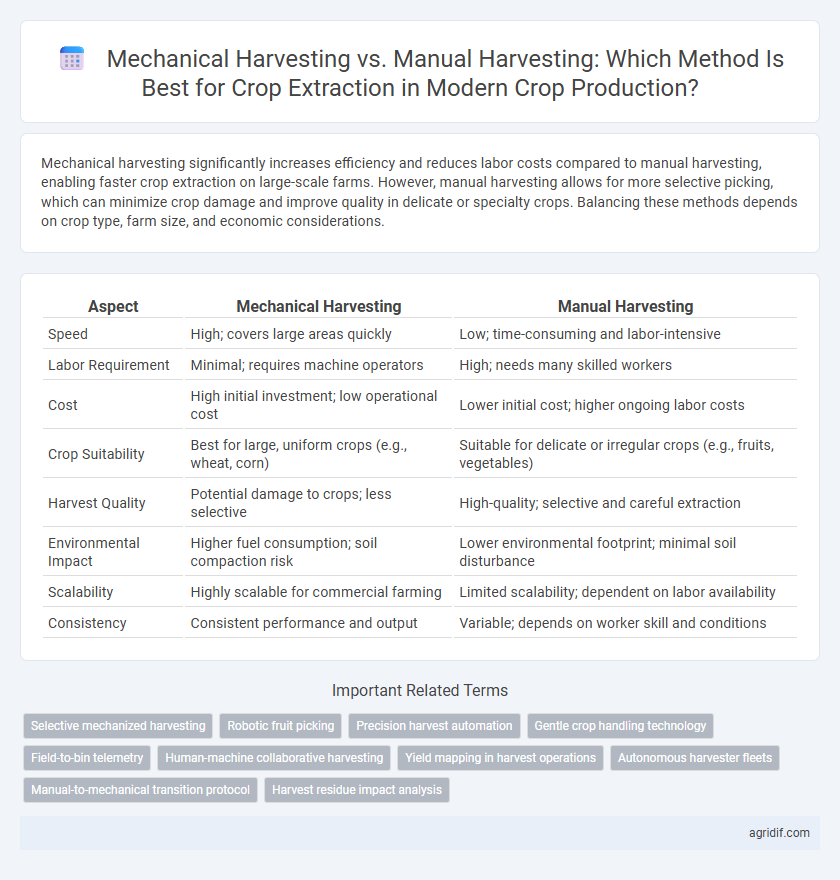

| Aspect | Mechanical Harvesting | Manual Harvesting |

|---|---|---|

| Speed | High; covers large areas quickly | Low; time-consuming and labor-intensive |

| Labor Requirement | Minimal; requires machine operators | High; needs many skilled workers |

| Cost | High initial investment; low operational cost | Lower initial cost; higher ongoing labor costs |

| Crop Suitability | Best for large, uniform crops (e.g., wheat, corn) | Suitable for delicate or irregular crops (e.g., fruits, vegetables) |

| Harvest Quality | Potential damage to crops; less selective | High-quality; selective and careful extraction |

| Environmental Impact | Higher fuel consumption; soil compaction risk | Lower environmental footprint; minimal soil disturbance |

| Scalability | Highly scalable for commercial farming | Limited scalability; dependent on labor availability |

| Consistency | Consistent performance and output | Variable; depends on worker skill and conditions |

Introduction to Crop Harvesting Methods

Mechanical harvesting uses advanced machinery like combine harvesters to efficiently collect crops, significantly increasing speed and reducing labor costs compared to manual methods. Manual harvesting relies on human labor to cut and gather crops, offering greater precision for delicate crops but limited scalability and higher labor expenses. Choosing between mechanical and manual harvesting depends on crop type, scale of production, and resource availability, impacting overall productivity and cost-efficiency.

Overview of Mechanical Harvesting in Agriculture

Mechanical harvesting in agriculture significantly increases efficiency and reduces labor costs by using advanced machinery such as combine harvesters, cotton pickers, and potato diggers. These machines enable large-scale crop extraction with greater speed and consistency, minimizing crop loss and improving yield quality. Adoption of mechanical harvesting is particularly beneficial for grains, legumes, and root crops, where precision and throughput directly impact productivity.

Manual Harvesting: Traditional Practices and Techniques

Manual harvesting relies on age-old techniques such as handpicking, sickle cutting, and selective harvesting, preserving crop quality and minimizing damage. This method allows farmers to carefully assess each plant for ripeness, ensuring optimal yield and reducing contamination from unripe or diseased produce. Despite being labor-intensive, manual harvesting remains vital for crops like fruits, vegetables, and specialty grains where precision and quality control are paramount.

Efficiency Comparison: Mechanical vs Manual Harvesting

Mechanical harvesting significantly increases efficiency by reducing labor hours and speeding up crop extraction, with machines capable of harvesting several acres per hour compared to manual methods that rely on slow, labor-intensive handpicking. Precision agriculture technologies integrated into mechanical harvesters optimize yield by minimizing crop damage and ensuring uniform harvesting. Manual harvesting offers higher selectivity and minimal damage for delicate crops but is less cost-effective for large-scale operations due to slower processing speeds and increased labor costs.

Labor Requirements and Workforce Implications

Mechanical harvesting significantly reduces labor requirements by automating crop extraction processes, enabling faster and more efficient harvesting over large areas. Manual harvesting demands extensive seasonal labor, often resulting in higher labor costs, variable worker availability, and increased risk of labor shortages during peak periods. The shift towards mechanization influences workforce dynamics by decreasing reliance on manual laborers while increasing the need for skilled operators and maintenance personnel.

Impact on Crop Yield and Quality

Mechanical harvesting significantly increases crop yield by enabling faster and more efficient extraction, reducing field losses caused by delayed gathering. However, it can sometimes cause physical damage to delicate crops, negatively affecting quality and market value compared to manual harvesting. Manual harvesting, while labor-intensive, allows for selective picking and better preservation of crop integrity, ultimately enhancing quality but often limiting overall yield due to slower processing times.

Cost Analysis: Investment and Operational Expenses

Mechanical harvesting requires significant initial investment in machinery, which can range from $50,000 to $200,000 depending on the equipment type and scale of operation. Operational expenses include fuel, maintenance, and skilled labor, generally resulting in lower per-unit costs compared to manual harvesting. Manual harvesting incurs minimal capital investment but higher labor costs and slower extraction rates, often making it less cost-effective for large-scale crop production.

Sustainability and Environmental Considerations

Mechanical harvesting significantly reduces labor intensity and increases efficiency but may contribute to soil compaction and higher energy consumption, impacting long-term soil health. Manual harvesting, while labor-intensive, allows for selective picking, reduces damage to crops and surrounding plants, and minimizes fossil fuel emissions, supporting biodiversity and sustainable land management. Sustainable crop production increasingly balances mechanical efficiency with environmental preservation through innovations like low-impact machinery and integrated pest management practices.

Safety and Health Risks for Farm Workers

Mechanical harvesting reduces physical strain and exposure to repetitive motions compared to manual harvesting, significantly lowering the risk of musculoskeletal disorders among farm workers. However, machinery operation introduces hazards such as accidents, noise-induced hearing loss, and exposure to airborne dust or chemicals during crop processing. Implementing proper safety protocols, personal protective equipment (PPE), and regular maintenance of harvesting equipment are essential to mitigate health risks in mechanized crop extraction.

Future Trends in Harvesting Technology

Mechanical harvesting is rapidly evolving with the integration of artificial intelligence and robotics, enabling higher precision and efficiency compared to manual harvesting. Future trends emphasize autonomous machinery equipped with advanced sensors and machine learning algorithms to optimize crop extraction while minimizing waste and labor costs. Innovations in drone-assisted monitoring and real-time data analytics also enhance decision-making for timely and scalable harvesting operations.

Related Important Terms

Selective mechanized harvesting

Selective mechanized harvesting enhances crop production efficiency by targeting mature plants with precision, reducing crop damage and minimizing labor costs compared to manual harvesting. Advanced technologies like optical sensors and machine learning enable real-time decision-making, optimizing yield quality and promoting sustainable agricultural practices.

Robotic fruit picking

Robotic fruit picking enhances crop production by increasing efficiency and consistency in harvesting delicate fruits compared to manual methods, reducing labor costs and minimizing damage. Mechanical harvesting, particularly through advanced robotics, enables precise identification and picking of ripe fruits, optimizing yield quality and supporting sustainable agricultural practices.

Precision harvest automation

Precision harvest automation enhances crop extraction efficiency by integrating advanced sensors and AI-driven machinery, outperforming manual harvesting in speed and accuracy. Mechanical harvesting reduces labor costs and crop damage, while precision technology ensures optimal yield by selectively targeting mature produce.

Gentle crop handling technology

Mechanical harvesting with gentle crop handling technology minimizes physical damage by using cushioned conveyors and controlled picking mechanisms, improving crop quality and reducing post-harvest losses compared to manual harvesting. This technology ensures efficient extraction while maintaining the integrity of delicate fruits and vegetables, enhancing overall productivity in crop production.

Field-to-bin telemetry

Mechanical harvesting enhances crop extraction efficiency by integrating field-to-bin telemetry, enabling real-time monitoring of yield, moisture levels, and equipment performance to optimize resource allocation. Manual harvesting lacks precise data feedback, limiting the ability to track crop quality and quantity from field to bin, thus reducing overall operational transparency and scalability.

Human-machine collaborative harvesting

Human-machine collaborative harvesting enhances crop production efficiency by integrating advanced mechanical harvesters with skilled labor, reducing crop damage and increasing throughput compared to purely manual or mechanical methods. This synergy optimizes resource use, minimizes labor costs, and adapts to variable field conditions, improving overall harvest quality and sustainability.

Yield mapping in harvest operations

Mechanical harvesting enhances yield mapping accuracy by integrating GPS and sensor technologies that collect precise data on crop output variability across fields, enabling optimized input management and improved decision-making. Manual harvesting, while labor-intensive and less consistent in spatial data collection, allows for selective picking that can impact yield quality but limits comprehensive yield mapping capabilities essential for precision agriculture.

Autonomous harvester fleets

Autonomous harvester fleets significantly enhance crop production efficiency by reducing labor costs and minimizing harvesting time compared to manual methods. These fleets leverage advanced sensors and AI technologies to optimize crop extraction, improve yield accuracy, and enable continuous operation in diverse field conditions.

Manual-to-mechanical transition protocol

The manual-to-mechanical transition protocol in crop production emphasizes systematic training for operators, calibration of harvesting machinery, and phased integration to minimize crop damage and labor disruption. Data-driven adjustments based on crop type, field conditions, and machinery performance ensure optimal efficiency and yield during the shift from manual to mechanical harvesting methods.

Harvest residue impact analysis

Mechanical harvesting generates higher volumes of harvest residue due to incomplete crop removal and plant material breakage, which can enhance soil organic matter but may require additional field clearance compared to manual harvesting. Manual harvesting produces less residue, allowing for cleaner fields but potentially reducing soil cover and increasing erosion risk, impacting long-term soil health and nutrient cycling in crop production systems.

Mechanical harvesting vs Manual harvesting for crop extraction Infographic

agridif.com

agridif.com