Automatic milking systems significantly enhance labor optimization by reducing the need for manual intervention, allowing dairy farmers to allocate time to other critical tasks. These systems provide consistent milking schedules and improve animal welfare through gentle, precise handling, which boosts milk yield and quality. In contrast, traditional milking requires more labor hours and can lead to inconsistent milking routines, increasing the risk of errors and fatigue among farm workers.

Table of Comparison

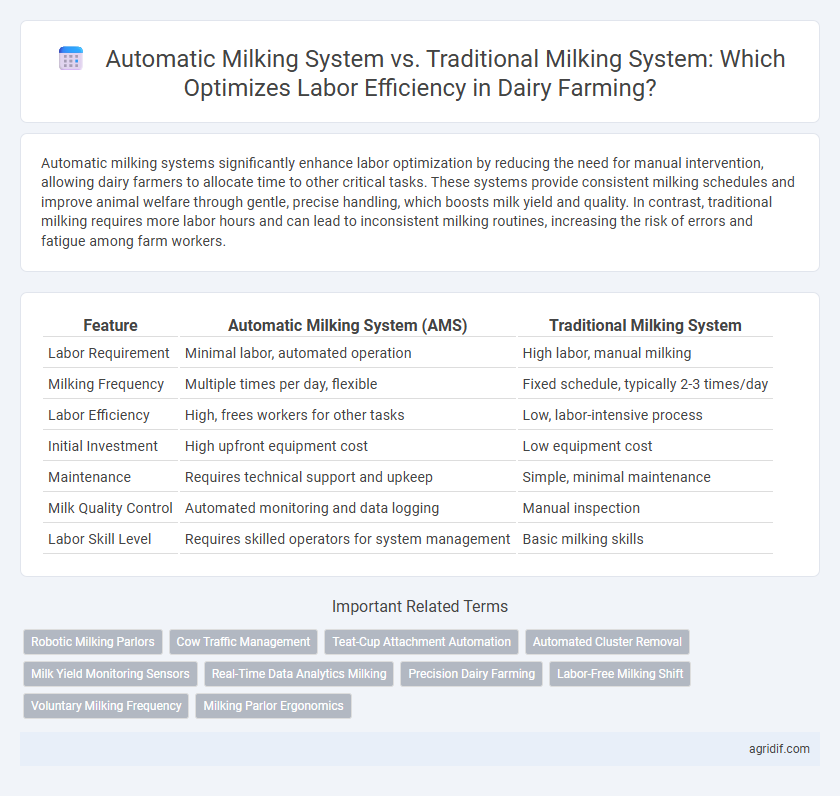

| Feature | Automatic Milking System (AMS) | Traditional Milking System |

|---|---|---|

| Labor Requirement | Minimal labor, automated operation | High labor, manual milking |

| Milking Frequency | Multiple times per day, flexible | Fixed schedule, typically 2-3 times/day |

| Labor Efficiency | High, frees workers for other tasks | Low, labor-intensive process |

| Initial Investment | High upfront equipment cost | Low equipment cost |

| Maintenance | Requires technical support and upkeep | Simple, minimal maintenance |

| Milk Quality Control | Automated monitoring and data logging | Manual inspection |

| Labor Skill Level | Requires skilled operators for system management | Basic milking skills |

Introduction to Milking Systems in Dairy Farming

Automatic milking systems (AMS) increase labor efficiency by reducing the need for manual intervention, enabling farmers to manage larger herds with fewer workers. Traditional milking systems require scheduled, labor-intensive processes, demanding consistent human presence and physical effort. Integration of AMS also enhances data collection for herd management, optimizing milk production and labor allocation.

Overview of Automatic Milking Systems (AMS)

Automatic Milking Systems (AMS) utilize robotics and advanced sensor technology to streamline the milking process, significantly reducing labor requirements compared to Traditional Milking Systems. These systems enable cows to be milked individually on demand, improving herd management efficiency and reducing manual intervention. Data integration in AMS supports monitoring animal health and production metrics, enhancing decision-making while optimizing labor allocation on dairy farms.

Traditional Milking Systems Explained

Traditional milking systems rely heavily on manual labor, requiring skilled workers to operate milking machines and handle cows directly, which can limit labor efficiency and increase operational costs. These systems often involve fixed schedules that demand consistent human presence, making it challenging to optimize labor resources and manage workforce flexibility. Despite these limitations, traditional milking remains widespread due to lower initial investment compared to automatic milking systems, though it generally results in higher ongoing labor expenses.

Labor Requirements: AMS vs Traditional Methods

Automatic milking systems (AMS) significantly reduce labor requirements by enabling cows to be milked without human intervention, allowing farm workers to focus on other critical tasks. Traditional milking systems demand consistent manual labor, requiring multiple workers to handle milking operations multiple times a day. AMS improves labor efficiency by minimizing the need for skilled milking labor and streamlining milk collection processes.

Efficiency and Productivity Comparison

Automatic milking systems enhance labor efficiency by reducing the time and manual effort required for milking, allowing farmers to manage larger herds with fewer workers. Traditional milking systems rely heavily on human labor, which limits scalability and can increase operational costs. Studies show automatic systems can improve milk yield consistency and overall productivity by optimizing milking frequency and animal comfort.

Impact on Labor Costs and Workforce Management

Automatic milking systems significantly reduce labor costs by minimizing the need for manual intervention, allowing a smaller workforce to manage larger herds efficiently. These systems enable more flexible workforce management by automating routine tasks such as milking, cleaning, and data collection, which traditionally require multiple labor hours daily. In contrast, traditional milking systems demand higher labor input for consistent performance, leading to increased labor expenses and complex scheduling challenges.

Animal Welfare and Milking Consistency

Automatic milking systems enhance animal welfare by allowing cows to be milked voluntarily, reducing stress and improving udder health through consistent milking intervals. These systems optimize labor by minimizing manual handling and enabling real-time monitoring of cow health and milk quality. Traditional milking methods often require scheduled labor and can introduce variability in milking consistency, potentially affecting both productivity and animal comfort.

Technological Investment and Maintenance Needs

Automatic milking systems require significant technological investment, including advanced robotics and sensor technologies, to optimize labor efficiency in dairy farming. These systems reduce manual labor through automation but demand routine maintenance and specialized technical support to ensure operational reliability. In contrast, traditional milking systems involve lower initial costs but rely heavily on manual labor, with simpler maintenance needs that are less technology-dependent.

Adaptability and Scalability in Dairy Operations

Automatic milking systems offer greater adaptability by accommodating fluctuating herd sizes and varying milking schedules without increasing labor demands. Traditional milking systems require proportional labor increases as herd size grows, limiting scalability and flexibility in dairy operations. Implementing automatic systems enables efficient labor optimization and seamless scalability, supporting dynamic farm management and enhancing overall productivity.

Choosing the Right Milking System for Labor Optimization

Automatic milking systems significantly reduce labor requirements by allowing cows to be milked without direct human intervention, enabling farmers to allocate workforce more efficiently and reduce labor costs. Traditional milking systems demand more manual labor, requiring consistent time and physical effort for operation, which can limit farm scalability and increase labor expenses. Choosing the right milking system depends on farm size, labor availability, and cost controls, with automatic systems offering substantial labor optimization benefits for larger or labor-constrained operations.

Related Important Terms

Robotic Milking Parlors

Robotic milking parlors enhance labor optimization by automating milk extraction, reducing manual tasks by up to 70% and allowing dairy farmers to reallocate labor toward herd management and maintenance. Compared to traditional milking systems, these automated units increase efficiency through precise scheduling and continuous monitoring, boosting overall productivity while minimizing labor costs.

Cow Traffic Management

Automatic milking systems improve labor optimization by enabling efficient cow traffic management through voluntary cow movement to milking stations, reducing the need for manual herding and labor-intensive scheduling. Traditional milking systems require scheduled manual gathering and herding of cows, increasing labor demands and limiting flexibility in daily farm operations.

Teat-Cup Attachment Automation

Automatic milking systems (AMS) enhance labor optimization by utilizing advanced teat-cup attachment automation, reducing the need for manual intervention and enabling continuous milking operations. In contrast, traditional milking systems rely on manual teat-cup attachment, increasing labor demands and limiting efficiency during peak milking times.

Automated Cluster Removal

Automated Cluster Removal (ACR) in Automatic Milking Systems significantly enhances labor efficiency by reducing the need for constant human supervision and intervention during milking, allowing farm workers to allocate time to other critical tasks. Traditional milking systems require manual cluster detachment, increasing labor demands and the risk of teat damage, whereas ACR ensures timely and precise cluster removal, improving overall milking routine productivity and animal welfare.

Milk Yield Monitoring Sensors

Automatic milking systems equipped with advanced milk yield monitoring sensors provide continuous, precise data collection, enabling real-time herd performance analysis and optimizing labor by reducing manual measurement tasks. Traditional milking systems rely on periodic manual measurements, which increase labor intensity and limit the accuracy and frequency of milk yield monitoring.

Real-Time Data Analytics Milking

Automatic milking systems leverage real-time data analytics to enhance labor optimization by continuously monitoring cow behavior, milk yield, and health indicators, reducing manual labor requirements and enabling precise herd management. Traditional milking systems lack integrated data capabilities, leading to increased labor intensity and less efficient decision-making based on irregular observations rather than continuous automated insights.

Precision Dairy Farming

Automatic milking systems enhance labor optimization in dairy farming by enabling cows to be milked individually on demand, reducing labor hours by up to 50% compared to traditional milking systems. Precision Dairy Farming technology integrates automated data collection on milk yield, cow health, and behavior, allowing for targeted interventions that improve overall farm efficiency and animal welfare.

Labor-Free Milking Shift

Automatic milking systems significantly reduce labor requirements by enabling a labor-free milking shift, allowing farmers to allocate their time to other essential tasks while cows are milked independently. Traditional milking systems demand continuous manual labor, increasing time and workforce costs, whereas automated systems optimize labor efficiency through technology-driven, hands-off operations.

Voluntary Milking Frequency

Automatic milking systems (AMS) increase voluntary milking frequency by allowing cows to be milked multiple times per day, enhancing labor efficiency through reduced manual intervention and better herd management. Traditional milking systems rely on fixed milking schedules, limiting milking frequency and requiring more intensive labor input for routine tasks.

Milking Parlor Ergonomics

Automatic milking systems enhance labor optimization by reducing repetitive physical strain and improving ergonomic conditions compared to traditional milking parlors, where workers face prolonged standing and awkward postures. These systems streamline milking processes with automated routines that minimize manual handling, leading to increased worker comfort and efficiency on dairy farms.

Automatic milking system vs Traditional milking system for labor optimization Infographic

agridif.com

agridif.com