Parlor milking requires skilled labor and scheduled herd management, offering efficiency in large-scale dairy operations but can be labor-intensive and stressful for cows. Robotic milking systems provide continuous, automated milk collection that enhances cow comfort and improves milk yield by allowing cows to be milked on their own schedule. Choosing between parlor and robotic milking depends on farm size, labor availability, and investment capacity, with robots typically boosting productivity and animal welfare.

Table of Comparison

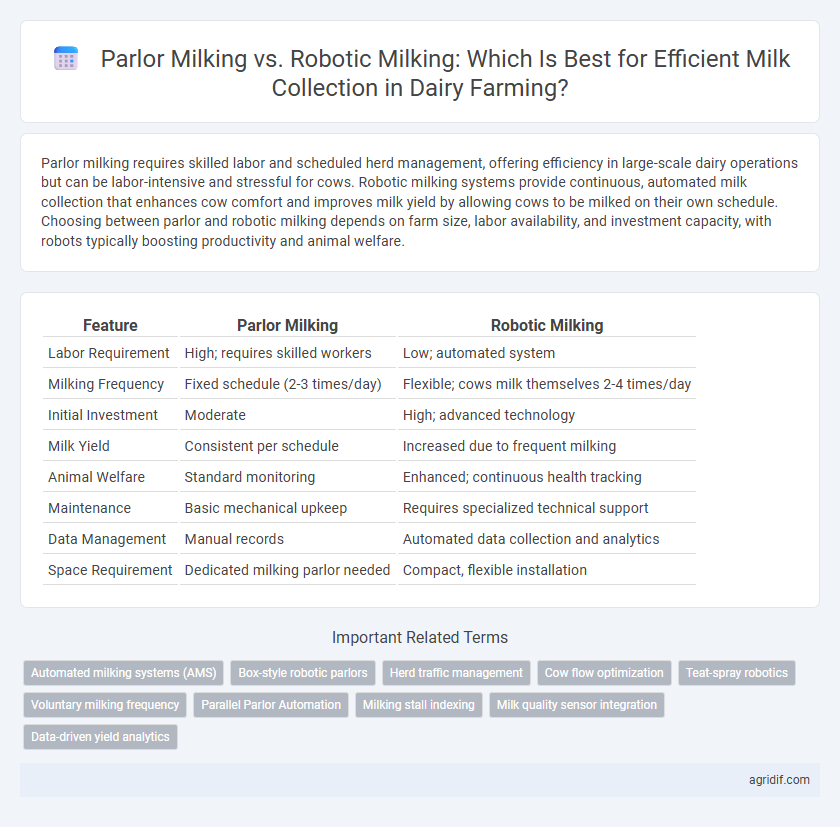

| Feature | Parlor Milking | Robotic Milking |

|---|---|---|

| Labor Requirement | High; requires skilled workers | Low; automated system |

| Milking Frequency | Fixed schedule (2-3 times/day) | Flexible; cows milk themselves 2-4 times/day |

| Initial Investment | Moderate | High; advanced technology |

| Milk Yield | Consistent per schedule | Increased due to frequent milking |

| Animal Welfare | Standard monitoring | Enhanced; continuous health tracking |

| Maintenance | Basic mechanical upkeep | Requires specialized technical support |

| Data Management | Manual records | Automated data collection and analytics |

| Space Requirement | Dedicated milking parlor needed | Compact, flexible installation |

Introduction to Modern Milking Methods

Modern milking methods in dairy farming primarily include parlor milking and robotic milking systems, each offering unique advantages for milk collection efficiency and animal welfare. Parlor milking involves manual or semi-automatic systems with high throughput capacity, ideal for large-scale operations requiring structured workflows. Robotic milking leverages automated technology with sensors and AI, enabling individualized cow management, reduced labor costs, and improved milking frequency.

Overview of Parlor Milking Systems

Parlor milking systems are a traditional method where cows enter a designated area to be milked by operators using milking machines, ensuring controlled and efficient milk collection. These systems offer high throughput and allow farmers to maintain strict hygiene and quality control standards during milking. Parlor milking is labor-intensive but provides consistent milk yield monitoring and herd management benefits compared to fully automated alternatives.

Understanding Robotic Milking Technology

Robotic milking technology revolutionizes dairy farming by automating the milking process, enhancing efficiency and animal welfare. Advanced sensors and AI systems detect cow health and optimize milk yield through precise teat cleaning and milking routines. This technology reduces labor costs and allows continuous milk collection, improving overall farm productivity compared to traditional parlor milking methods.

Efficiency and Labor Requirements

Parlor milking systems streamline milk collection through structured workflows, requiring a skilled labor force to manage multiple cows simultaneously, which enhances operational efficiency in large-scale dairy farms. Robotic milking systems automate the process, reducing labor demands by allowing cows to be milked on their own schedule, increasing milking frequency and improving milk yield. While parlor milking depends heavily on trained personnel for timely operations, robotic milking delivers consistent efficiency by minimizing labor input and optimizing herd management through data analytics.

Animal Welfare and Cow Comfort

Robotic milking systems enhance animal welfare by allowing cows to choose milking times, reducing stress and promoting natural behavior, which supports better udder health and comfort. Parlor milking, while traditional and efficient for large herds, can induce stress due to forced milking schedules and handling, potentially affecting cow comfort negatively. Implementing robotic milking technologies often leads to improved cow welfare metrics such as lower somatic cell counts and decreased lameness incidence.

Milk Quality and Hygiene Standards

Parlor milking systems allow controlled environments that enhance milk quality by reducing contamination through standardized hygiene protocols. Robotic milking machines automatically clean teats before milking and continuously monitor milk quality parameters, ensuring consistent hygiene and reducing bacterial counts. Both methods prioritize maintaining optimal milk quality but robotic systems offer real-time data analytics for immediate quality control improvements.

Investment Costs and Economic Considerations

Parlor milking systems require lower initial investment costs compared to robotic milking, which involves high upfront expenses for automation technology and integration. Economic considerations for parlor milking include labor costs and efficiency, as manual operation demands skilled workers but offers predictable maintenance, while robotic milking reduces labor costs and enables 24/7 operation but requires ongoing technical support and higher depreciation. Choosing between these systems depends on herd size, labor availability, and long-term financial planning for maximizing return on investment in dairy farming.

Technological Maintenance and Scalability

Parlor milking systems require regular manual maintenance and skilled labor to manage mechanical components, limiting scalability in large-scale operations. Robotic milking machines integrate automated diagnostics and remote monitoring, reducing downtime and maintenance complexity while supporting scalable herd sizes with minimal human intervention. Investment in robotic systems facilitates efficient scalability by optimizing labor resources and ensuring consistent technological upkeep.

Farmer Workload and Lifestyle Impact

Parlor milking demands intensive manual labor with scheduled milking times, increasing farmer workload and limiting flexibility in daily routines. Robotic milking systems automate the process, reducing physical strain and allowing farmers to manage multiple tasks, resulting in enhanced lifestyle balance and more efficient herd management. Adoption of robotic milking can improve work-life harmony, but requires initial investment and technical proficiency.

Future Trends in Dairy Milking Systems

Robotic milking systems increasingly dominate future trends in dairy farming by enhancing efficiency and animal welfare through automated, non-invasive milk collection and real-time monitoring of cow health. Parlor milking, while still prevalent, faces limitations in scalability and labor reduction compared to advanced robotic units integrated with AI-driven analytics and IoT connectivity. Emerging technologies focus on precision livestock farming, aiming to optimize milk yield, reduce labor costs, and improve sustainability in dairy operations.

Related Important Terms

Automated milking systems (AMS)

Automated milking systems (AMS) enhance dairy farm efficiency by enabling robotic milking, which reduces labor costs and increases milking frequency compared to traditional parlor milking methods. AMS technology collects precise data on milk yield and cow health, optimizing herd management and improving overall milk quality.

Box-style robotic parlors

Box-style robotic parlors enhance dairy farming efficiency by automating milk collection through individual stalls equipped with sensors, reducing labor costs and improving animal welfare. Compared to traditional parlor milking, these systems optimize milk yield and data accuracy by enabling continuous, stress-free milking aligned with cows' natural rhythms.

Herd traffic management

Parlor milking requires scheduled herd movement, often limiting cow traffic flow and potentially causing stress, whereas robotic milking systems enable voluntary cow traffic, improving herd welfare and optimizing milk yield through more natural milking frequencies. Efficient herd traffic management in robotic systems reduces labor costs and enhances barn hygiene by minimizing crowding and injury risks.

Cow flow optimization

Parlor milking systems facilitate controlled cow flow through structured milking stations, allowing for predictable herd movement and efficient labor management. Robotic milking enhances cow flow optimization by enabling voluntary milking schedules, reducing stress, and increasing milking frequency, which leads to improved milk yield and animal welfare.

Teat-spray robotics

Parlor milking systems rely on manual teat-spray application, which can lead to inconsistent coverage and increased risk of mastitis, while robotic milking integrates automated teat-spray robotics, ensuring precise and hygienic application that enhances udder health and milk quality. Teat-spray robotics use sensors and targeted spraying technology to uniformly disinfect teats post-milking, reducing bacterial contamination and improving overall dairy farm productivity.

Voluntary milking frequency

Robotic milking systems enable voluntary milking frequency, allowing cows to be milked multiple times per day based on their natural behavior, which improves milk yield and animal welfare. In contrast, parlor milking follows a fixed schedule that limits the potential for increased milking frequency and may not align with individual cow milking needs.

Parallel Parlor Automation

Parallel Parlor Automation in dairy farming enhances efficiency by allowing multiple cows to be milked simultaneously with minimal labor, improving milk yield consistency and animal welfare. Compared to robotic milking, parallel parlors offer faster throughput and better control over milking parameters, optimizing overall herd productivity.

Milking stall indexing

Milking stall indexing in parlor milking requires precise synchronization of cows entering fixed stalls, optimizing throughput but limiting flexibility during peak times. Robotic milking systems utilize automated, sensor-driven indexing to manage cow flow dynamically, enhancing milking frequency and improving animal welfare by allowing cows to self-select milking times.

Milk quality sensor integration

Parlor milking systems with integrated milk quality sensors enable real-time monitoring of somatic cell count, conductivity, and milk temperature, ensuring immediate detection of mastitis and other milk quality issues. Robotic milking machines enhance this process by continuously collecting high-resolution data per cow, optimizing milk yield and health management through advanced sensor technology and automated data analytics.

Data-driven yield analytics

Parlor milking offers controlled milk collection with manual oversight, enabling real-time yield monitoring but limited data granularity, while robotic milking systems utilize integrated sensors and AI-driven analytics to provide continuous, detailed milk yield data and health metrics for each cow, optimizing herd management. Advanced data-driven yield analytics from robotic milking enhance milk production forecasting and herd performance evaluation, driving precision dairy farming decisions.

Parlor milking vs Robotic milking for milk collection Infographic

agridif.com

agridif.com