Parlor milking offers a controlled environment ideal for small herds, ensuring consistent hygiene and animal comfort during the milking process. Pipeline milking provides efficiency by reducing labor and time, allowing farmers to milk animals directly in the barn, which can minimize stress for the herd. Choosing between the two depends on the farm's layout, budget, and the dairy farmer's priorities for herd management and milk quality.

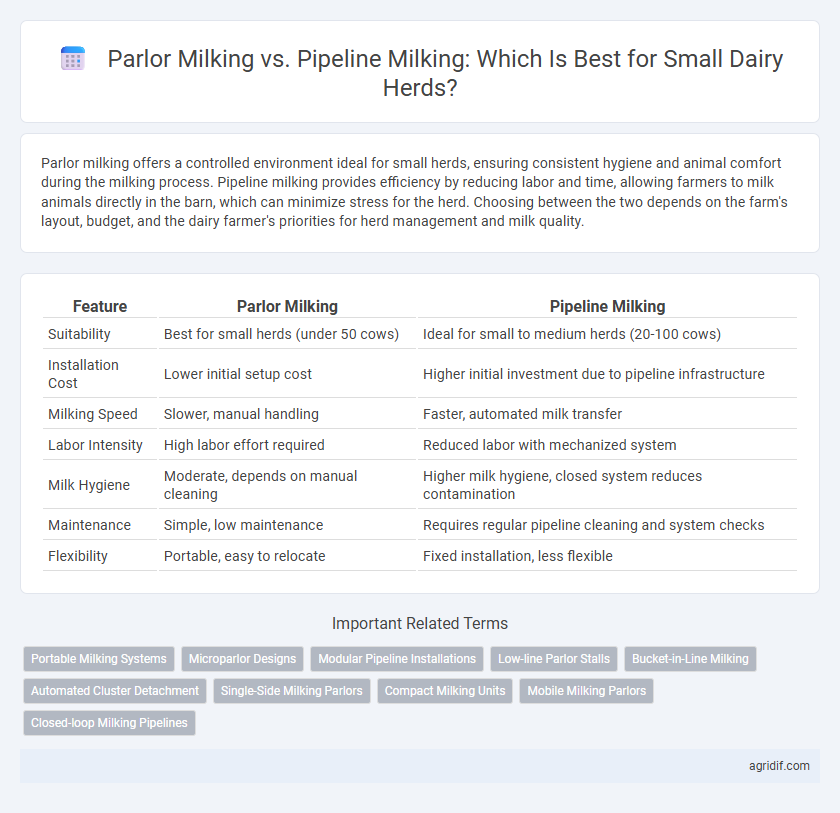

Table of Comparison

| Feature | Parlor Milking | Pipeline Milking |

|---|---|---|

| Suitability | Best for small herds (under 50 cows) | Ideal for small to medium herds (20-100 cows) |

| Installation Cost | Lower initial setup cost | Higher initial investment due to pipeline infrastructure |

| Milking Speed | Slower, manual handling | Faster, automated milk transfer |

| Labor Intensity | High labor effort required | Reduced labor with mechanized system |

| Milk Hygiene | Moderate, depends on manual cleaning | Higher milk hygiene, closed system reduces contamination |

| Maintenance | Simple, low maintenance | Requires regular pipeline cleaning and system checks |

| Flexibility | Portable, easy to relocate | Fixed installation, less flexible |

Introduction to Milking Systems for Small Dairy Herds

Parlor milking systems offer flexibility and ease of monitoring individual cows, making them ideal for small dairy herds of fewer than 50 cows. Pipeline milking systems streamline milk transfer directly from the milking station to the bulk tank, reducing labor but requiring higher initial investment and maintenance. Choosing between these systems depends on herd size, farm layout, and budget constraints specific to small-scale dairy operations.

What is Parlor Milking?

Parlor milking is a method where cows are brought into a designated area equipped with milking stalls, allowing farmers to milk multiple cows simultaneously using milking machines. This system offers controlled hygiene and efficient milk collection, making it suitable for small herds ranging from 20 to 100 cows. Parlor milking minimizes labor intensity and improves milk quality by providing a clean and organized environment.

Understanding Pipeline Milking

Pipeline milking systems streamline the milking process by directly transporting milk from individual cows to a central storage tank, reducing labor and contamination risks. For small herds, this method offers efficient hygiene control and minimizes the need for manual handling compared to parlor milking. Proper installation and maintenance of pipeline equipment are essential to maximize milk quality and operational efficiency in small-scale dairy farms.

Equipment Requirements: Parlor vs Pipeline

Parlor milking systems for small herds require a structured setup including milking stalls, vacuum pumps, pulsators, and a milk collection tank, emphasizing flexibility and control but often need more initial investment space. Pipeline milking systems involve fixed pipelines that directly transport milk to a bulk tank, reducing manual handling and labor, with equipment such as stainless steel pipelines, vacuum lines, and bulk milk cooling tanks necessitating precise installation. Small herd operations benefit from pipeline milking's streamlined equipment reducing labor, while parlor milking's modular components offer easier scalability and customization.

Labor Efficiency in Small-Scale Operations

Pipeline milking systems enhance labor efficiency in small-scale dairy farms by reducing the need for manual handling and streamlining the milking process. Parlor milking may require more time and physical effort per cow, making it less efficient for limited labor resources. Implementing pipeline systems can optimize workflow, cut down milking time, and increase overall productivity in small herds.

Milk Quality and Hygiene Comparison

Parlor milking offers enhanced control over the milking process, leading to improved milk quality through reduced contamination and precise udder cleaning. Pipeline milking systems provide consistent hygiene by minimizing manual handling and exposure to external contaminants, which helps maintain uniform milk standards. For small herds, choosing between parlor and pipeline milking depends on balancing the need for personalized udder care with the efficiency of automated milk transport to optimize overall milk hygiene and quality.

Installation and Maintenance Costs

Parlor milking systems typically require higher initial installation costs due to the need for specialized equipment and dedicated milking spaces, making them less cost-effective for small herds. Pipeline milking systems offer lower installation expenses by integrating milking lines directly within barn structures, reducing setup complexity and capital investment. Maintenance costs for pipeline systems are generally lower since they involve fewer mechanical components and simpler cleaning procedures compared to parlor setups.

Space and Infrastructure Demands

Parlor milking requires more dedicated space and structural investment, including a separate milking area with stalls and walkways designed for animal movement and worker accessibility. Pipeline milking systems demand less physical space as they integrate milking lines directly from the barn, reducing the need for a standalone parlor and minimizing infrastructure costs. For small herds, pipeline milking offers a compact, efficient solution with lower spatial and infrastructure requirements compared to traditional parlor setups.

Animal Comfort and Handling

Parlor milking offers individualized animal comfort by allowing cows to be milked in a controlled environment with gentle handling, reducing stress and promoting consistent milk flow. Pipeline milking systems for small herds enhance efficiency by minimizing cow movement and streamlining the milking process, though they may require more careful management to maintain animal comfort and ensure proper hygiene. Prioritizing gentle handling and minimizing cow stress in either system leads to improved milk quality and overall herd health.

Choosing the Right System for Small Herds

Parlor milking suits small herds by offering ergonomic workstations and precise control over each cow, enhancing milk quality and udder health. Pipeline milking integrates directly with bulk tanks, streamlining the milking process while reducing labor and equipment costs, ideal for confined spaces. Assess factors like herd size, labor availability, investment capacity, and milking frequency to determine the most efficient and sustainable system for small-scale dairy operations.

Related Important Terms

Portable Milking Systems

Portable milking systems offer a flexible and cost-effective solution for small herds, enabling farmers to easily move equipment and milk cows in different locations without extensive infrastructure. Compared to traditional parlor milking, pipeline milking systems reduce labor time and enhance milk quality by minimizing contamination risks through closed, sanitary pipelines.

Microparlor Designs

Microparlor designs optimize pipeline milking for small herds by enhancing space efficiency and reducing labor compared to traditional parlor milking systems. These compact setups streamline milk flow directly into bulk tanks, improving hygiene and milk quality while minimizing animal stress.

Modular Pipeline Installations

Modular pipeline installations offer flexible, scalable solutions ideal for small dairy herds, allowing incremental expansion without major disruptions. These systems ensure efficient milking by integrating customized pipeline components, improving hygiene and reducing labor compared to traditional parlor milking setups.

Low-line Parlor Stalls

Low-line parlor stalls offer ergonomic benefits and efficient cow traffic flow, making them ideal for small herd dairy farms that prioritize comfort and milking speed. Compared to pipeline milking, low-line parlor systems enhance udder health by reducing contamination risks while optimizing milk yield consistency and labor efficiency.

Bucket-in-Line Milking

Bucket-in-line milking systems offer small herd dairy farms flexibility and cost-efficiency by enabling individual teat cups to collect milk directly into a portable bucket, reducing initial infrastructure investment compared to pipeline milking. This method enhances maneuverability and ease of maintenance while maintaining milk quality through controlled vacuum pulsation, making it ideal for farms with limited herd sizes under 50 cows.

Automated Cluster Detachment

Automated cluster detachment in parlor milking systems enhances milking efficiency and reduces labor by automatically removing clusters when milk flow drops, minimizing teat damage and overmilking in small herds. Pipeline milking with automated detachment offers streamlined workflows but may involve higher initial setup costs and requires proper maintenance to ensure consistent sensor performance and animal comfort.

Single-Side Milking Parlors

Single-side milking parlors provide efficient space utilization and ease of cow handling for small dairy herds compared to traditional pipeline milking systems, which may require more manual labor and space. These parlors optimize milking speed and hygiene by centralizing equipment and reducing cow movement, enhancing productivity for farms managing limited herd sizes.

Compact Milking Units

Compact milking units in parlor milking provide greater flexibility and ease of operation for small herds, optimizing labor efficiency and milk quality control. Pipeline milking systems reduce physical strain by allowing direct milk transport from cow to bulk tank, enhancing hygiene and minimizing contamination risks in limited-space dairy setups.

Mobile Milking Parlors

Mobile milking parlors offer small herds flexibility and efficiency by enabling on-site milking without permanent infrastructure, reducing labor and cow stress compared to traditional pipeline milking systems. These portable units integrate automated milking technology that enhances udder health monitoring and milk quality, making them ideal for rotational grazing setups.

Closed-loop Milking Pipelines

Closed-loop milking pipelines offer small herd dairy farms a hygienic and efficient alternative to traditional parlor milking by minimizing milk contamination and reducing labor time through automated cleaning and milk transfer systems. These sealed systems enhance milk quality and animal comfort while streamlining milking operations, making them ideal for small-scale dairy producers seeking productivity and sanitation improvements.

Parlor Milking vs Pipeline Milking for Small Herds Infographic

agridif.com

agridif.com