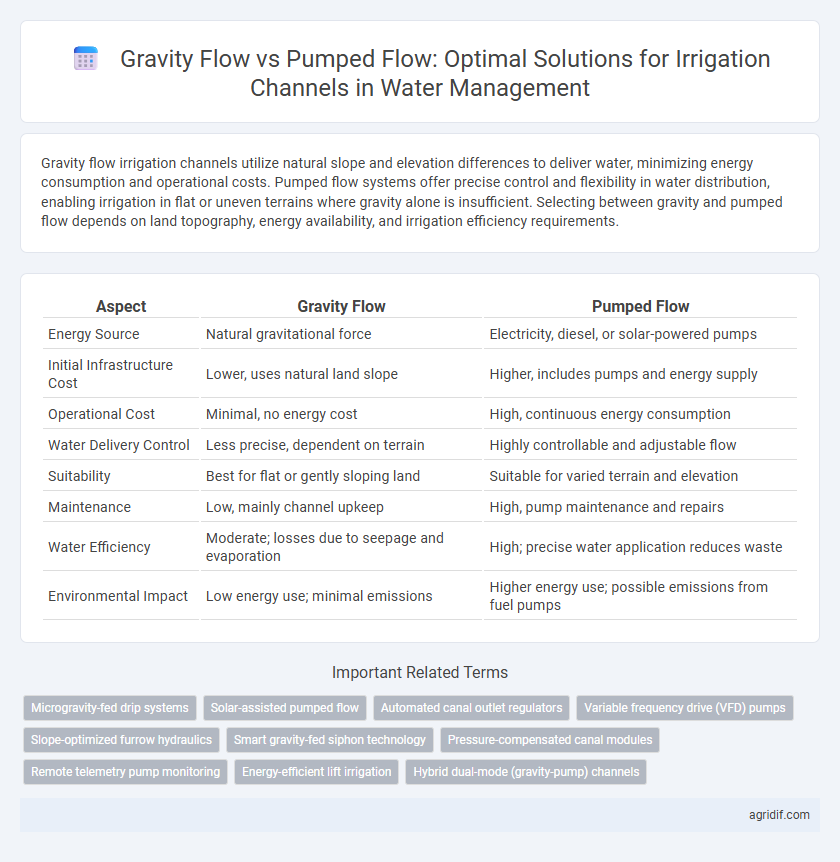

Gravity flow irrigation channels utilize natural slope and elevation differences to deliver water, minimizing energy consumption and operational costs. Pumped flow systems offer precise control and flexibility in water distribution, enabling irrigation in flat or uneven terrains where gravity alone is insufficient. Selecting between gravity and pumped flow depends on land topography, energy availability, and irrigation efficiency requirements.

Table of Comparison

| Aspect | Gravity Flow | Pumped Flow |

|---|---|---|

| Energy Source | Natural gravitational force | Electricity, diesel, or solar-powered pumps |

| Initial Infrastructure Cost | Lower, uses natural land slope | Higher, includes pumps and energy supply |

| Operational Cost | Minimal, no energy cost | High, continuous energy consumption |

| Water Delivery Control | Less precise, dependent on terrain | Highly controllable and adjustable flow |

| Suitability | Best for flat or gently sloping land | Suitable for varied terrain and elevation |

| Maintenance | Low, mainly channel upkeep | High, pump maintenance and repairs |

| Water Efficiency | Moderate; losses due to seepage and evaporation | High; precise water application reduces waste |

| Environmental Impact | Low energy use; minimal emissions | Higher energy use; possible emissions from fuel pumps |

Introduction to Gravity Flow and Pumped Flow in Irrigation

Gravity flow irrigation utilizes natural land gradients to move water through channels, minimizing energy costs and reducing infrastructure complexity. Pumped flow systems rely on mechanical pumps to distribute water, allowing precise control over flow rates and enabling irrigation on flat or uneven terrain where gravity alone is insufficient. Understanding the fundamental differences in energy consumption, control, and terrain adaptability is crucial for optimizing irrigation system design and water management efficiency.

Principles of Gravity Flow Irrigation Channels

Gravity flow irrigation channels rely on the natural slope of the terrain to convey water from sources like rivers or reservoirs to agricultural fields, minimizing energy consumption. These channels are designed based on principles of hydraulics, including channel slope, cross-sectional area, and roughness, to ensure uniform water distribution and prevent erosion. Properly designed gravity flow systems optimize water use efficiency by controlling flow velocity and maintaining adequate depth through earth-lined or concrete channels.

Mechanisms and Applications of Pumped Flow Systems

Pumped flow systems in irrigation utilize mechanical pumps such as centrifugal or submersible pumps to lift and convey water, enabling precise control over water distribution in areas lacking natural elevation gradients. These systems are essential for irrigating terrains with low or irregular slopes, facilitating efficient water delivery in agricultural fields where gravity flow is insufficient. Advanced pumped irrigation setups integrate variable speed drives and automated controls, optimizing water use efficiency and enabling large-scale, uniform irrigation across diverse crop types.

Energy Efficiency: Gravity vs Pumped Flow

Gravity flow irrigation channels leverage natural elevation differences to move water without external energy inputs, resulting in significantly higher energy efficiency compared to pumped flow systems. Pumped flow requires electricity or fuel to operate pumps, leading to increased operational costs and carbon emissions. Optimizing channel design in gravity flow systems reduces water losses and enhances sustainable water management practices.

Water Distribution Uniformity in Both Systems

Gravity flow irrigation channels offer high water distribution uniformity by relying on natural slope and controlled channel design, minimizing energy use and reducing pressure variations. Pumped flow systems enable precise regulation of water delivery rates, enhancing uniformity through adjustable pressure and flow control, especially in uneven terrain or varying crop demands. Optimal water distribution in both systems depends on channel design, maintenance, and flow regulation techniques tailored to specific field conditions.

Cost Analysis: Installation and Operational Expenses

Gravity flow irrigation channels typically incur lower installation costs due to minimal mechanical components and reduced energy requirements, making them economically favorable in regions with suitable topography. Pumped flow systems demand higher initial investment for pumps, motors, and control units, alongside ongoing operational expenses driven by electricity or fuel consumption. Over the long term, gravity flow offers cost savings through minimal maintenance and zero energy costs, whereas pumped flow provides enhanced control and flexibility but at increased financial burden.

Environmental Impact: Gravity Flow vs Pumped Flow

Gravity flow irrigation channels reduce energy consumption and greenhouse gas emissions by relying on natural water gradients, making them more environmentally sustainable than pumped flow systems. Pumped flow irrigation demands significant electricity or fuel, contributing to higher carbon footprints and potential water source depletion due to over-extraction. Efficient gravity flow designs optimize water distribution while minimizing soil erosion and habitat disruption, preserving local ecosystems better than mechanically driven alternatives.

Maintenance Requirements and Longevity

Gravity flow irrigation channels generally require less maintenance due to the absence of mechanical parts prone to wear and failure, enhancing their longevity when designed with proper slope and filtration. Pumped flow systems involve regular maintenance of pumps, motors, and electrical components, which increases operational costs and shortens equipment lifespan if not properly serviced. Well-maintained gravity flow channels can function efficiently for decades, whereas pumped systems typically have a shorter service life dependent on the maintenance schedule and component quality.

Suitability for Different Terrain and Crop Types

Gravity flow irrigation channels excel in gently sloped terrains and are ideal for crops like rice and sugarcane that benefit from uniform water distribution through surface irrigation. Pumped flow systems offer greater flexibility for uneven or flat terrains, supporting high-value crops such as vegetables and fruits that require precise water control and varying flow rates. Selecting between gravity and pumped flow depends on terrain gradients, soil infiltration rates, and specific crop water requirements to optimize irrigation efficiency and crop yield.

Decision-Making Factors for Optimal System Selection

Decision-making factors for selecting gravity flow versus pumped flow in irrigation channels include water source availability, topography, and energy costs. Gravity flow systems are optimal in areas with favorable slopes and access to elevated water sources, minimizing energy consumption and maintenance. Pumped flow systems offer flexibility in flat terrains or where water must be lifted, requiring careful evaluation of pump efficiency, operational costs, and reliability for sustainable water management.

Related Important Terms

Microgravity-fed drip systems

Microgravity-fed drip systems utilize gravity flow to deliver water efficiently, reducing energy costs and minimizing mechanical failures compared to pumped flow systems in irrigation channels. These systems optimize water distribution by leveraging natural elevation differences, enhancing irrigation uniformity and conserving water resources in agricultural practices.

Solar-assisted pumped flow

Solar-assisted pumped flow in irrigation channels offers higher control over water distribution and efficiency compared to traditional gravity flow systems, especially in large-scale agricultural operations. Integrating photovoltaic technology reduces energy costs and environmental impact while enabling irrigation in areas with inadequate natural water gradients.

Automated canal outlet regulators

Automated canal outlet regulators in gravity flow irrigation utilize gravitational force to control water distribution with minimal energy use, enhancing efficiency in water delivery and reducing operational costs. Pumped flow systems require energy-intensive equipment to manage water pressure and distribution but offer greater control and flexibility in irrigation scheduling and flow rates.

Variable frequency drive (VFD) pumps

Variable frequency drive (VFD) pumps enhance pumped flow irrigation systems by enabling precise control over water discharge rates, leading to significant energy savings and optimized water use compared to traditional gravity flow channels. Integration of VFD technology reduces pump wear and allows adaptive response to changing crop water requirements, improving overall irrigation efficiency and sustainability.

Slope-optimized furrow hydraulics

Slope-optimized furrow hydraulics enhance gravity flow irrigation channels by utilizing natural terrain gradients to maximize water distribution efficiency and minimize energy consumption. Pumped flow irrigation allows precise control over discharge rates but requires additional energy input, making gravity flow more sustainable for fields with adequate slope and soil infiltration characteristics.

Smart gravity-fed siphon technology

Smart gravity-fed siphon technology enhances irrigation efficiency by minimizing energy consumption and enabling precise water delivery in gravity flow systems. Unlike pumped flow methods, it leverages natural hydraulic forces, reducing operational costs while maintaining optimal soil moisture levels for sustainable crop production.

Pressure-compensated canal modules

Pressure-compensated canal modules enhance gravity flow irrigation channels by maintaining consistent water distribution regardless of elevation changes, reducing energy costs compared to pumped flow systems that rely on mechanical pressure. This technology optimizes water use efficiency and minimizes sediment buildup, benefiting large-scale agricultural irrigation schemes.

Remote telemetry pump monitoring

Gravity flow irrigation channels offer energy-efficient water delivery but limited control and responsiveness, whereas pumped flow systems enable precise water management and scheduling. Remote telemetry pump monitoring enhances pumped flow efficiency by providing real-time data on pump performance, flow rates, and system faults, enabling timely maintenance and optimized water use.

Energy-efficient lift irrigation

Gravity flow irrigation channels utilize natural terrain elevation to deliver water efficiently without external energy, significantly reducing operational costs compared to pumped flow systems. Pumped flow irrigation, although offering precise water delivery and adaptability to flat or uneven terrains, typically consumes higher energy, making gravity-fed systems more sustainable and cost-effective for large-scale lift irrigation projects.

Hybrid dual-mode (gravity-pump) channels

Hybrid dual-mode irrigation channels combine gravity flow and pumped flow systems to optimize water distribution efficiency and energy use. This approach leverages gravity for baseline water movement while activating pumps during low-gradient sections or variable demand periods, enhancing overall irrigation control and reducing operational costs.

Gravity flow vs Pumped flow for irrigation channels Infographic

agridif.com

agridif.com